This is an old revision of the document!

28.15. Wastage Prediction due to expiry when ordering

The problem

Prior to mSupply v7.12, when ordering or reporting on suggested ordering, you could simply tell mSupply to ignore stock that was going to expiry in three or four months time. mSupply would then lower it's stock level and order according to usages.

However due to popular demand with mSupply v7.12 we have tried to do a better job of predicting stock wastage due to expiry. Using the consumption data that we have, we have travelled into the future and worked out the likely wastage stock. This page describes the workflow.

Suggested Order reports

Lets look at a report in mSupply v7.12 or later.

From mSupply activate the menu :

- Report > Purchasing > Suggested Order quantities…

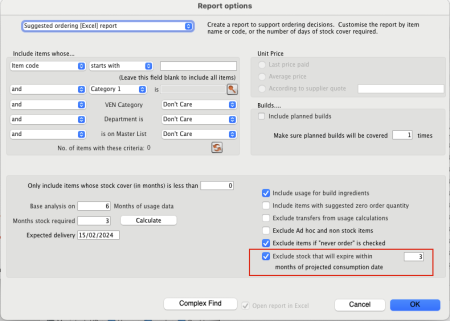

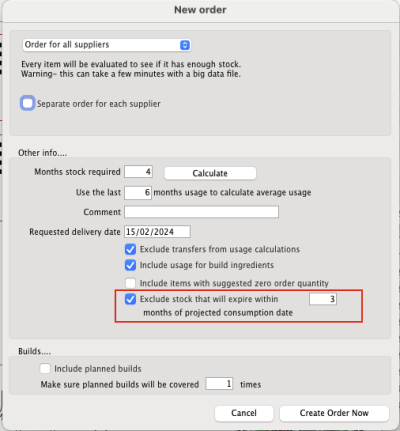

The Suggested ordering report now has a new/updated expiry filter checkbox : Exclude stock that will expire within 3 months of projected consumption date

This checkbox accurately takes into account the likelihood of current stock expiring in the future based on the monthly calculated consumption for an item while determining the suggested order quantities. Previously you could tell mSupply to ignore stock that was close to expiry by say 3 or 6 months when calculating quantities, however this is approximate.

With mSupply version v7.12, mSupply has the option to accurately analyse the stock quantities that can’t be distributed due the consumption rate and the expiry date of the stock. This results in a more accurate estimate of the suggested order quantities.

The workflow :

Imagine we have the following batches for an item.

| Item | Batch | Stock | Expiry |

|---|---|---|---|

| Amoxycillin/ Clavulanic acid 30mg | b12-2023 | 500 | 12/2023 |

| Amoxycillin/ Clavulanic acid 30mg | b06-2024 | 550 | 06/2024 |

| Amoxycillin/ Clavulanic acid 30mg | b06-2025 | 100 | 06/2025 |

- Imagine the current date is 1/1/2024

- Imagine the AMC is 50

- Imagine you need stock for 12 months.

- When running the report this is checked : Exclude stock that will expire within 3 months of projected consumption date

When the above report is run, mSupply will immediately ignore the batch `b12-2023` as it has already expired as the current date is `1/1/2024`.

For batch `b06-2024` : mSupply works out that you can only dispense this batch till the end of April 2024, due to the set 3 months cutt-off date for expiry. So the months that this stock cane be dispensed are :

- January 2024

- February 2024

- March 2024

- April 2024

So the stock that can be used from batch `b06-2024` is : 4 * 50 = 200. ( In the reports that you will see in the future, this is known as effective stock) So the wasted quantity for batch `b06-2024` is : 550 - 200 = 350 (This is expiring stock, 350 will need to be thrown away. In the reports that you will see in the future, this is shown as Expiring stock )

For batch `b06-2025` : So from May 2024, mSupply will need to start using this batch for distribution. So this is 8 months remaining from May 2024 - to December 2024. However with a stock of just `100` this item will be used up during the following two months :

- May 2024

- June 2024

So for batch `b06-2025` all the stock will be used up and they will be no wastage.

However we now have 6 months starting from July 2024 till the end of December 2024 where we don’t have any stock, so mSupply will suggest a immediate order of : 6 * 50 =300 to cope with the 12 months starting from `1/1/2024`

mSupply has effectively time travelled into the future to work out the Effective Stock on hand (SOH) and the order will be carried out based on this and not the current stock on hand.

New Columns on Suggested order reports and changes

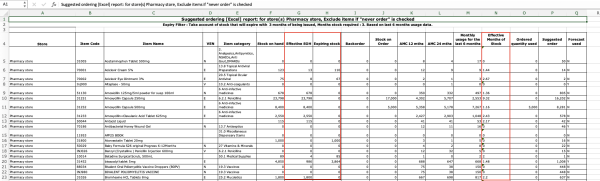

Now the suggested ordering reports will have two new column :

- Effective SOH (Stock on Hand) : From above this is the stock quantities that can be used before they expire.

- Expiring stock : This is the stock quantity that can’t be used due to predicted expiry and cut-off date.

The `Effective Month of Stock` is now calculated from the `Effective SOH` and not from the `Stock on Hand`. The `Suggested order` is now calculated from the `Effective SOH` and the `Effective Month of Stock`.