This is an old revision of the document!

12.02. Ordering Process with Supplier Hub

The complete ordering process for the supplier hub is summarised in the diagram below:

- The customer creates a purchase order in their mSupply instance (top left in the diagram) which, when confirmed, is sent to the Supplier Hub.

- The Supplier hub sends this as a customer requisition to the supplier’s mSupply instance.

- The supplier creates a customer invoice from the customer requisition; this determines the stock that is sent to the customer.

- Once finalised, the customer invoice is sent to the Supplier hub as an Advance Shipping Notification (ASN).

- The customer receives this as a Goods Received note in their mSupply instance.

- The Goods Received note can be edited to correctly reflect the stock received in the customer's store.

- Once finalised, the Goods Received note information is updated on the customer's original purchase order and sent to the Supplier Hub. It then updates the customer invoice originally created in the supplier's mSupply instance to show the quantity, batches and date or reception of the stock received.

Ordering from a Supplier Hub site

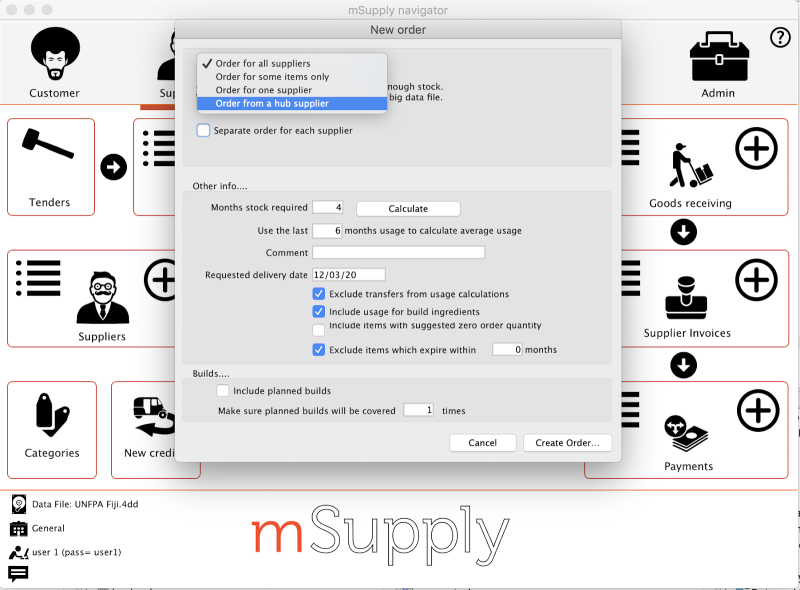

- Click ‘Calculated’ on the Supplier tab to create a new calculated purchase order.

- Choose ‘Order from a hub supplier’ in the drop down list.

- This will then allow you to search from the supplier hub suppliers

- Once chosen, it will create a purchase order for the items in the Supplier Hub Catalog for that supplier (See Supplier Hub Config - Setting up Catalogs for how these catalogs are defined).

- The purchase order must be confirmed for the order to be sent to the supplier hub.

| Previous: 12.01. Configuring the mSupply Link | | Next: 12.03. Supplying a mSupply Link site |