This is an old revision of the document!

test - all namespaces

1.01. Introduction

Thank you for choosing mSupply. mSupply is now a family of software products, a team of trainers and consultants. Before you launch in (if you haven't already!), we suggest you plan to take the following steps.

- Get a feel for Open mSupply. If you're running a vertically integrated supply chain, Open mSupply will likely work well for you. It is open source (free of charge) and is the product that The mSupply Foundation is prioritising for development. As of February 2025, a proprietary Legacy mSupply Central server is still required at the core of an mSupply installation, but most stores in the supply chain below the 'central' store(s) can be Open mSupply. The plan is to develop all of the central server functionality in Open mSupply.

- Read the rest of this introduction.

- Read the setup, tutorial and licence chapters in this manual.

Please note that installation requires basic computer skills:

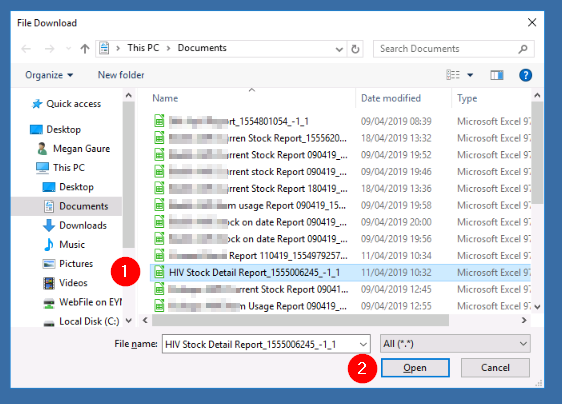

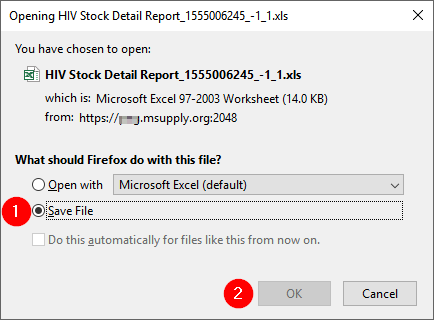

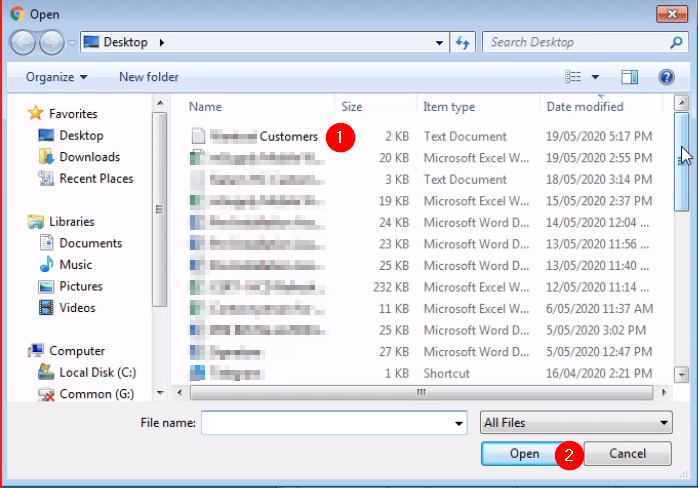

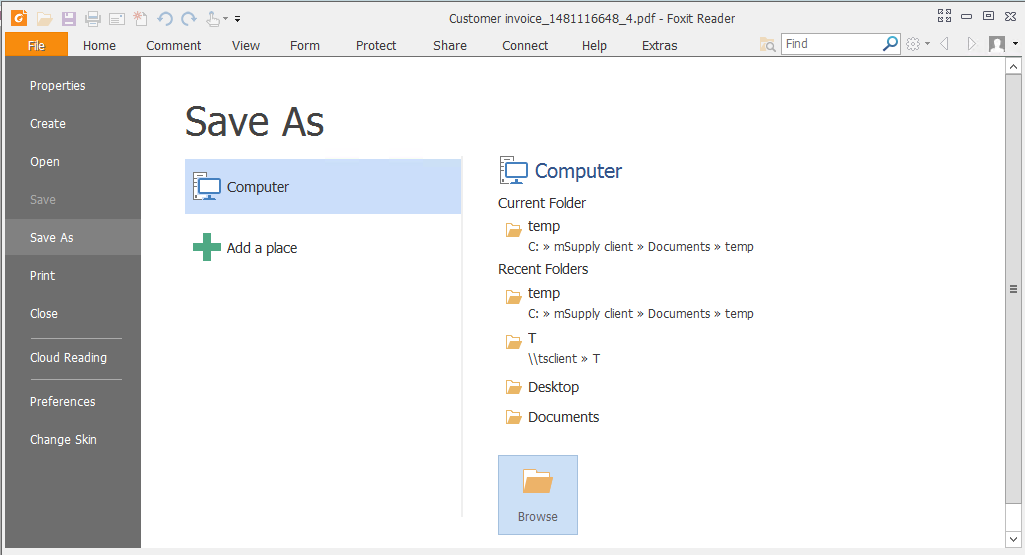

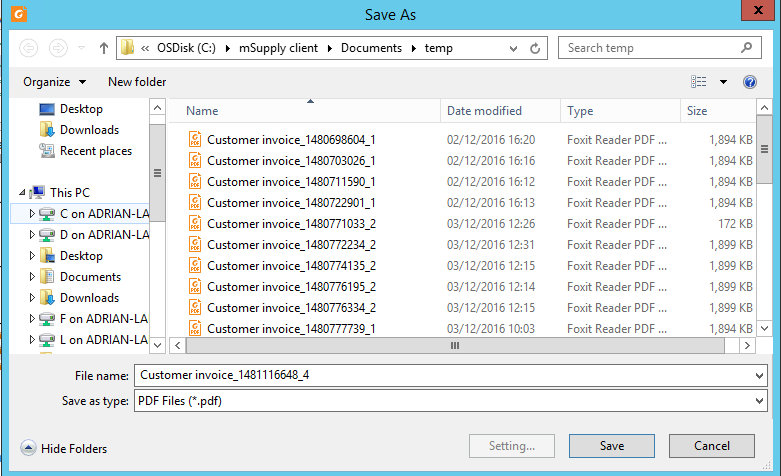

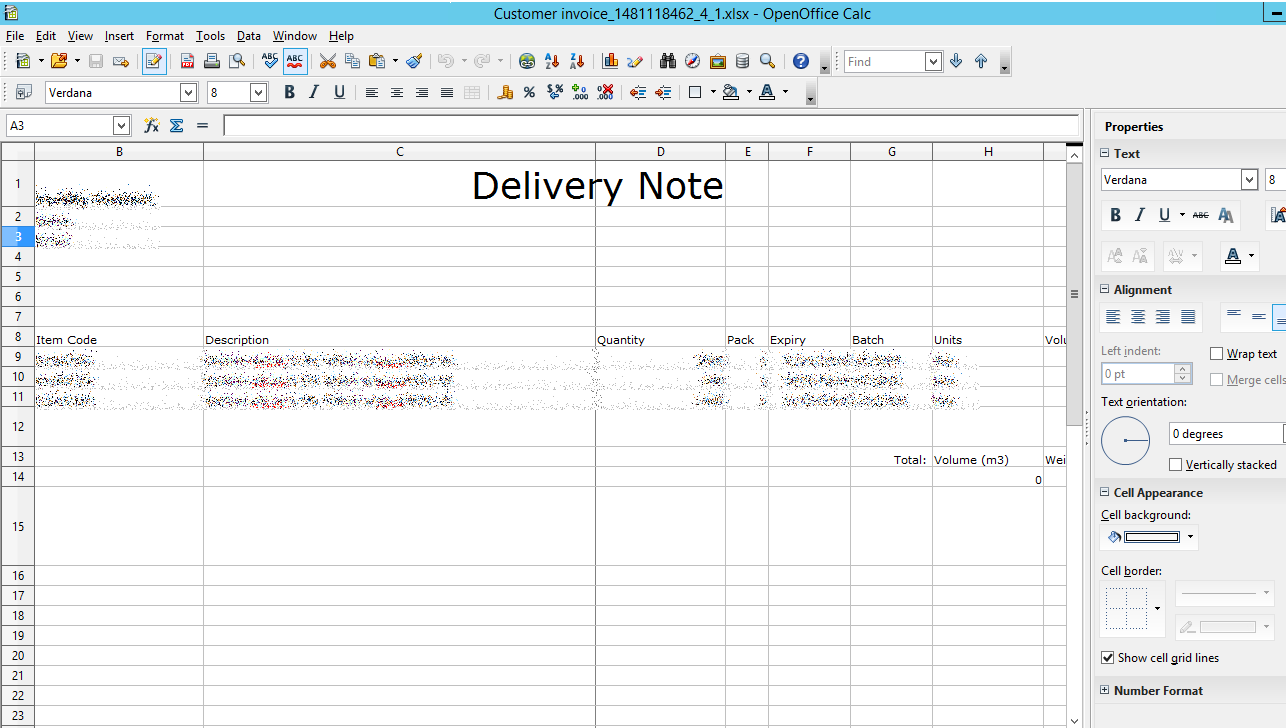

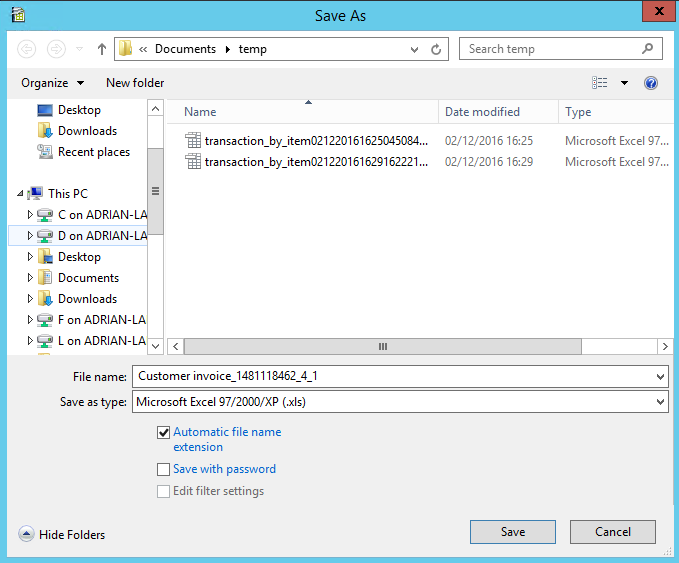

- You need to be able to locate a file using the “open” and “save” windows.

- If you are not sure, why not try, and email us if you get stuck.

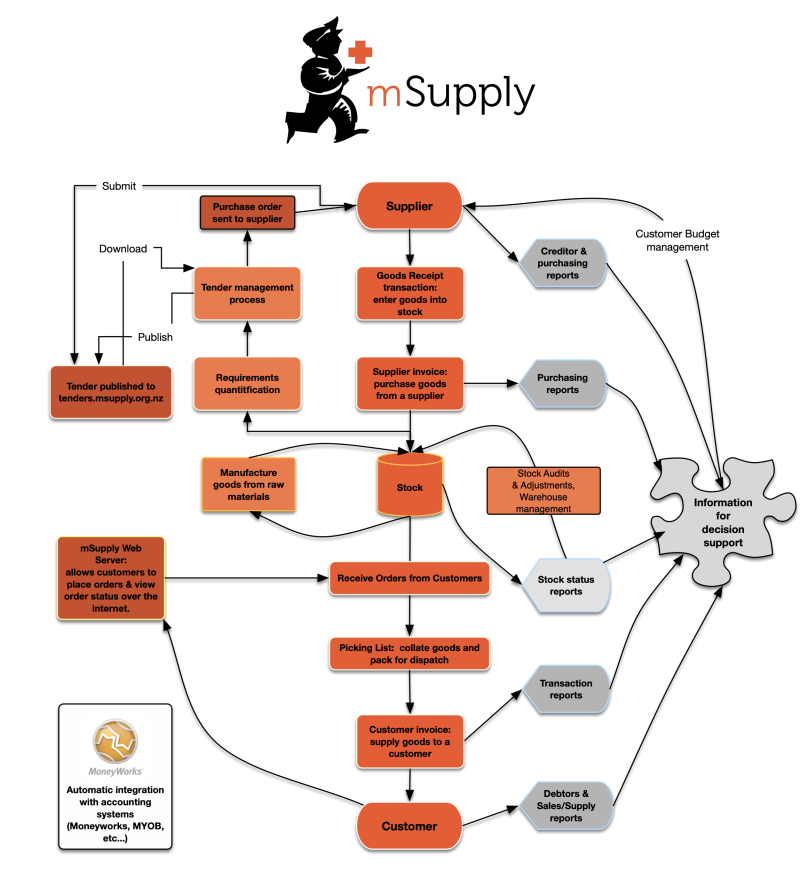

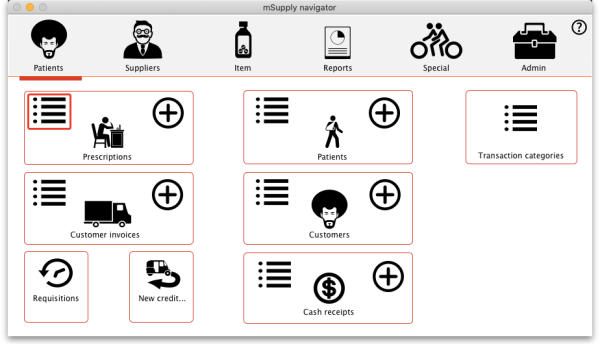

mSupply is designed to handle the following tasks:

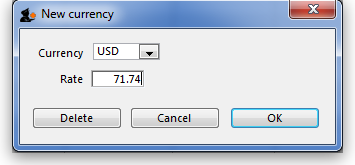

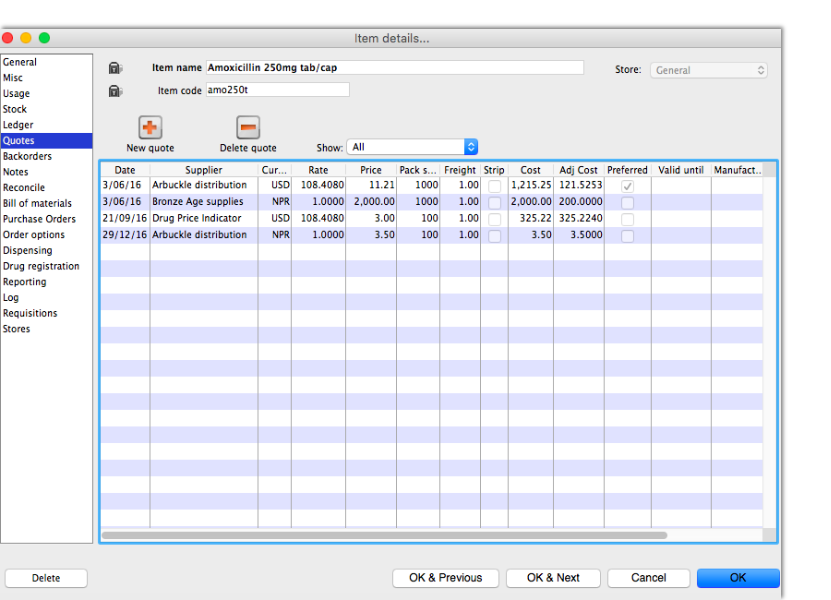

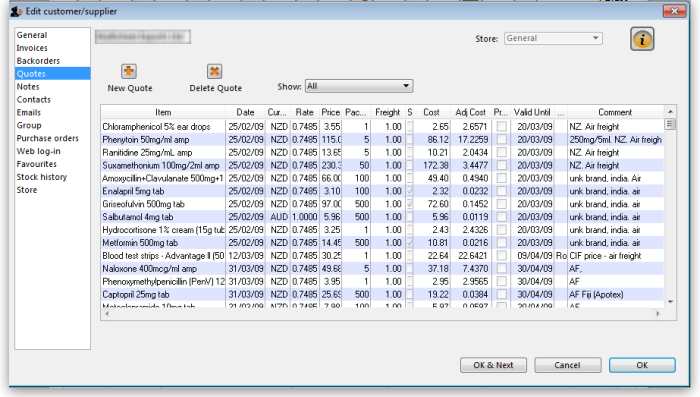

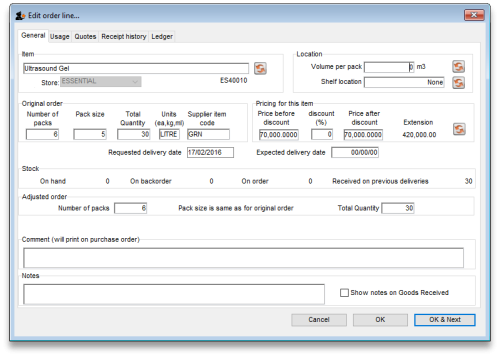

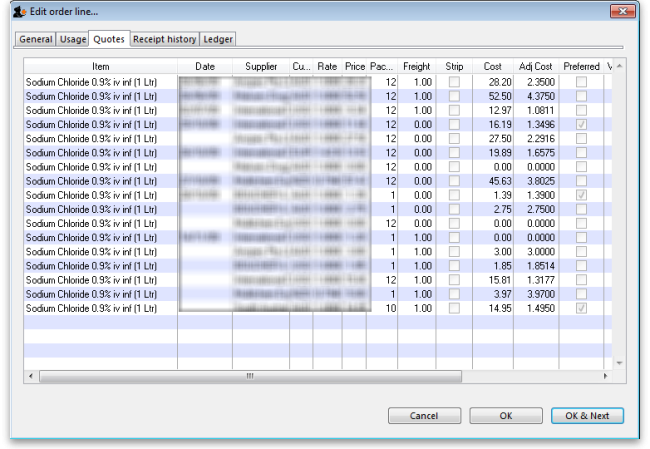

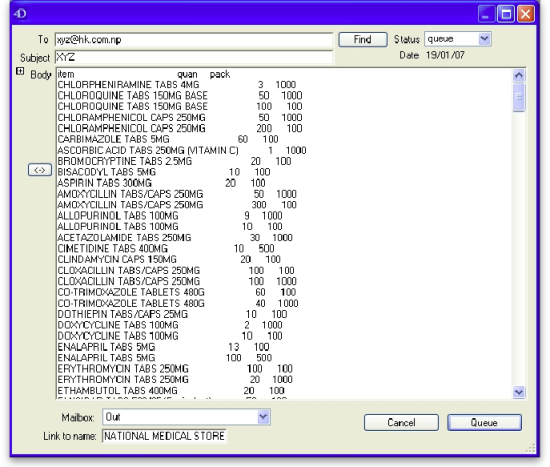

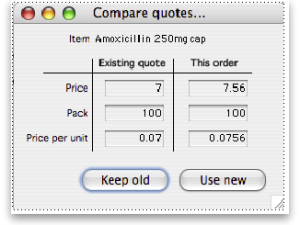

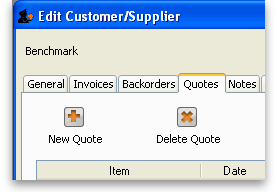

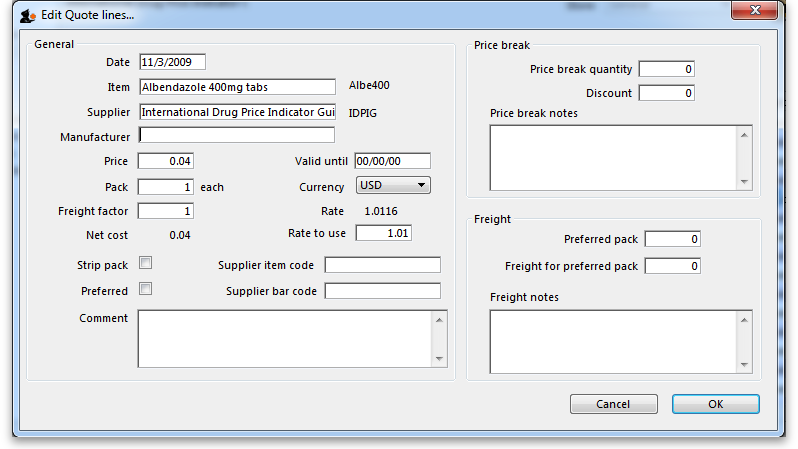

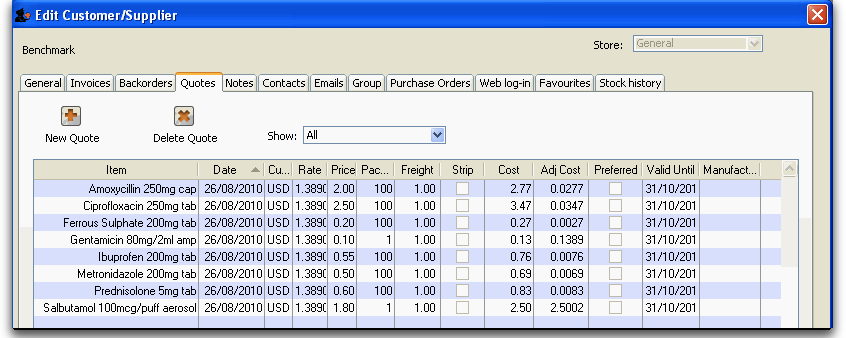

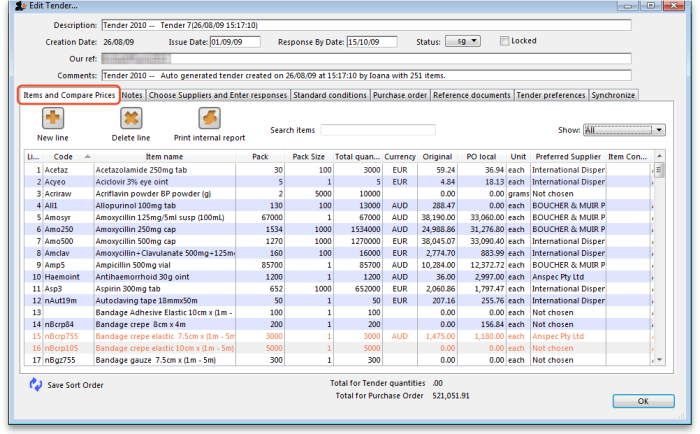

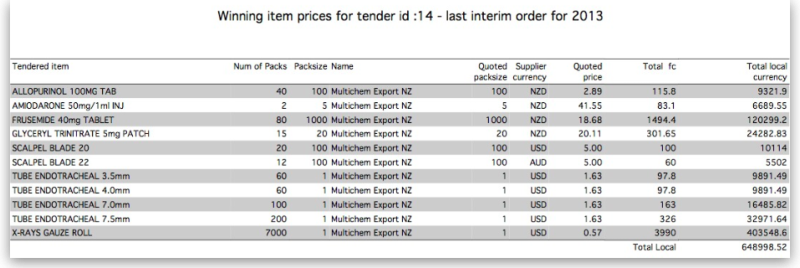

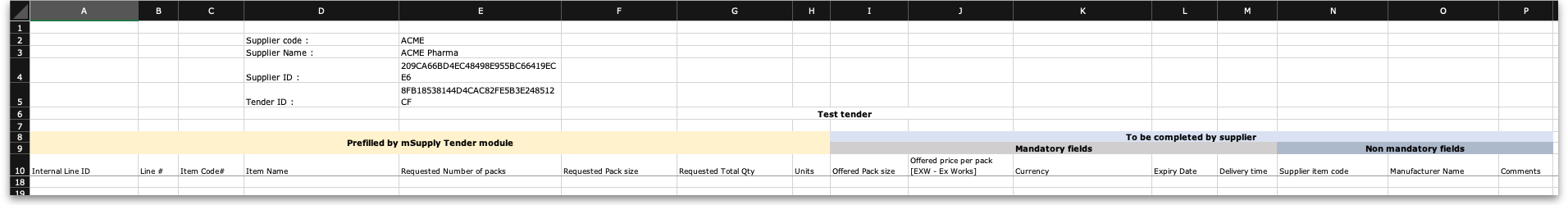

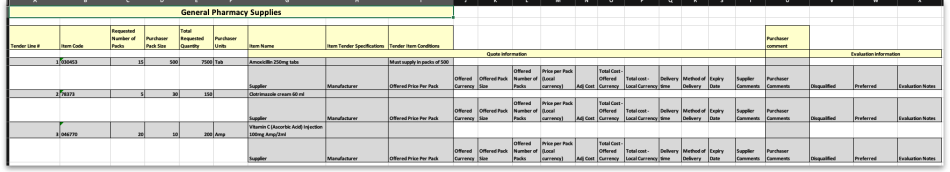

- Recording quotations received from various suppliers in a way that makes for easy comparison of true cost prices.

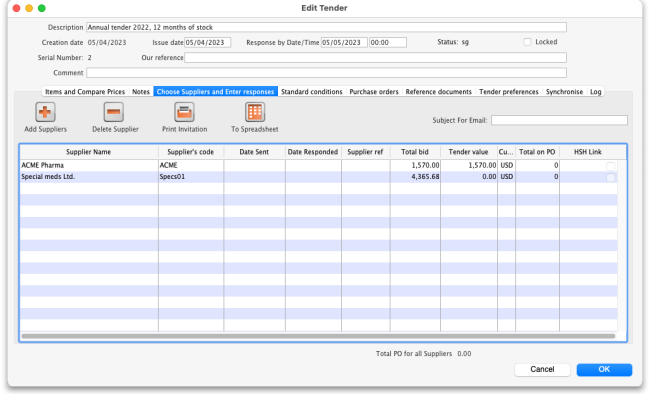

- Create tenders for suppliers to respond to.

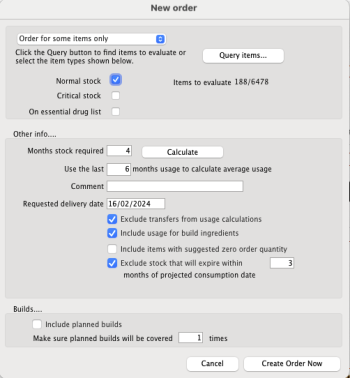

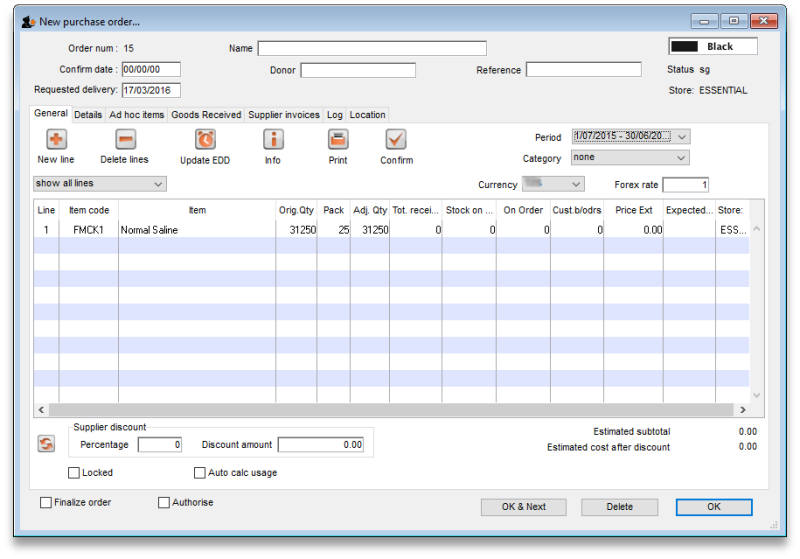

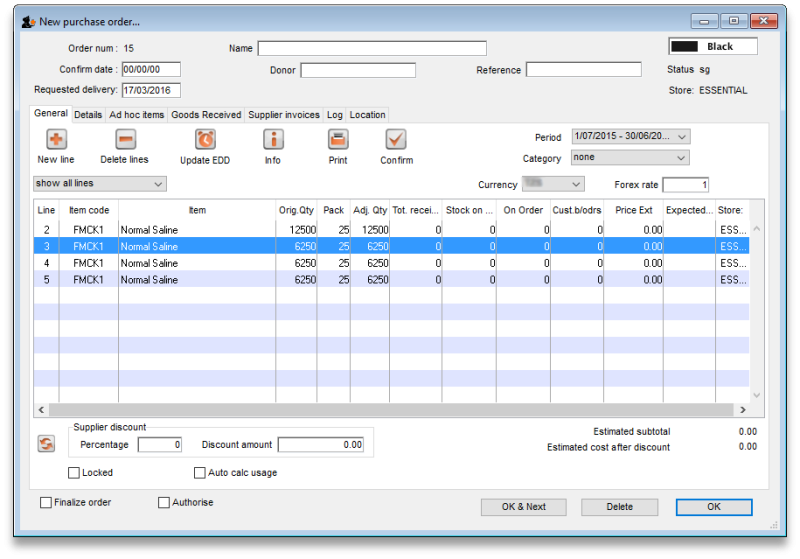

- Ordering (Purchasing) of items from a particular supplier, using actual usage figures to calculate the required quantities.

- Entering of incoming goods into inventory.

- Manufacturing items. That is, building new items from raw materials in your stock.

- Tracking Accounts Payable and Accounts Receivable

- Issuing of invoices for customers, and recording the transaction against inventory.

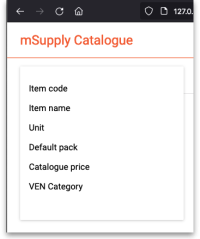

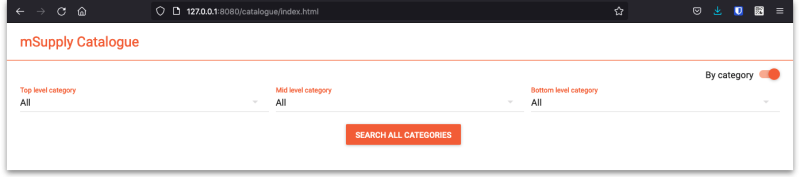

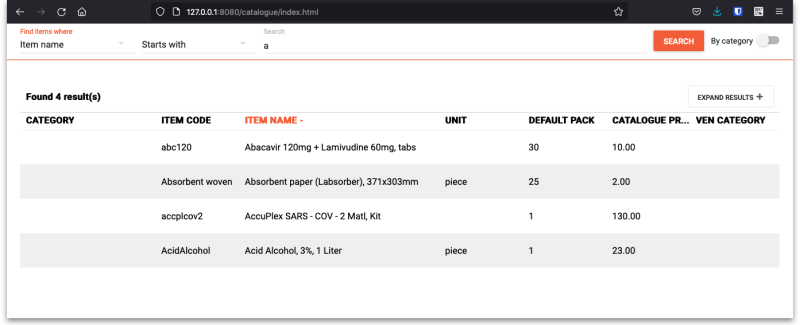

- Customers are able to order on-line via the internet, and can view stock status and the status of their orders.

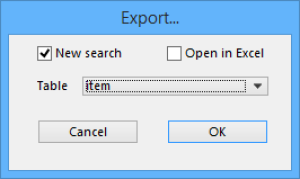

- Exporting purchase and invoice data for import into an accounting program.

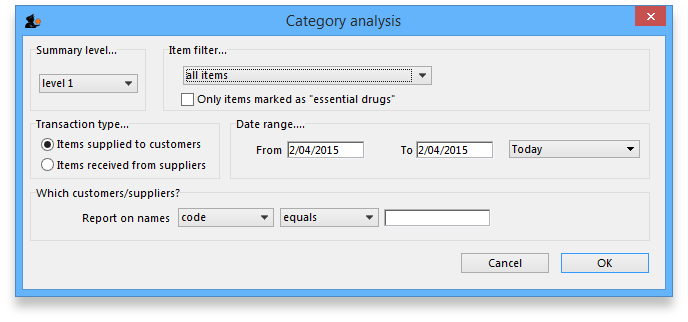

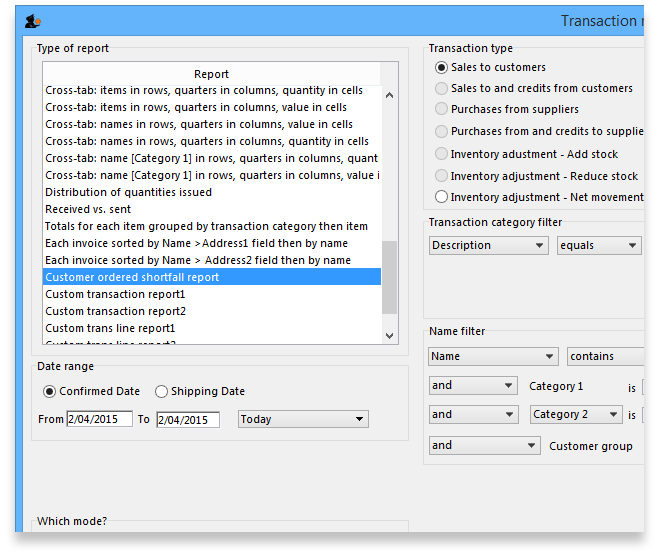

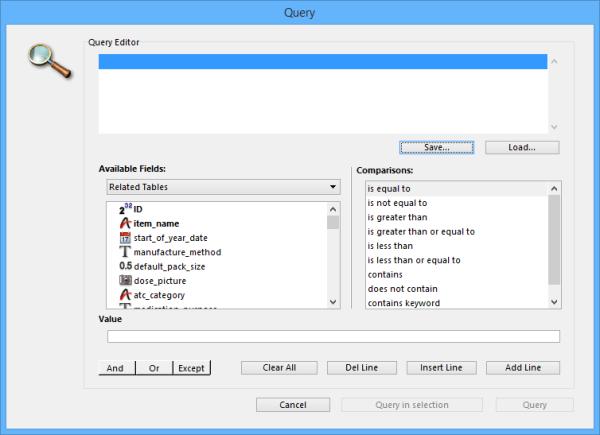

- Reporting on transactions and other data in almost any manner you want!

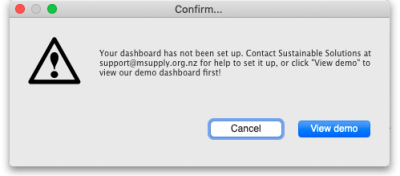

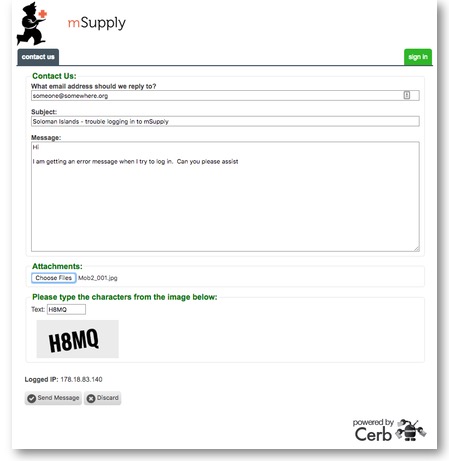

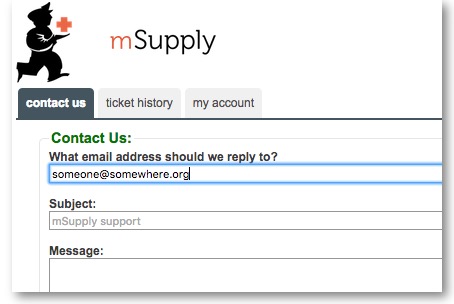

- If you need help with installing mSupply please feel free to email us at support@msupply.org.nz

About this user guide

The latest and most authoritative version of this User Guide is located on-line at http://docs.msupply.org.nz/. You can export the chapter you're viewing in PDF format by clicking the export:pdf tab to the right. It may then be viewed off-line within Acrobat Reader or other PDF viewer. To obtain the whole user guide in PDF format, visit mSupply site

If you are reading a PDF version, it is likely that a more up-to-date version is available on-line.

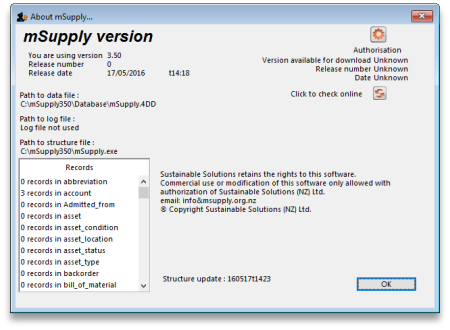

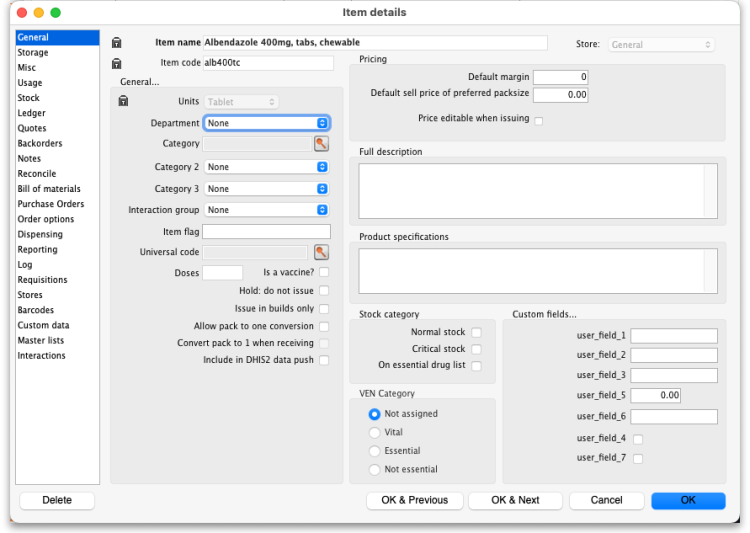

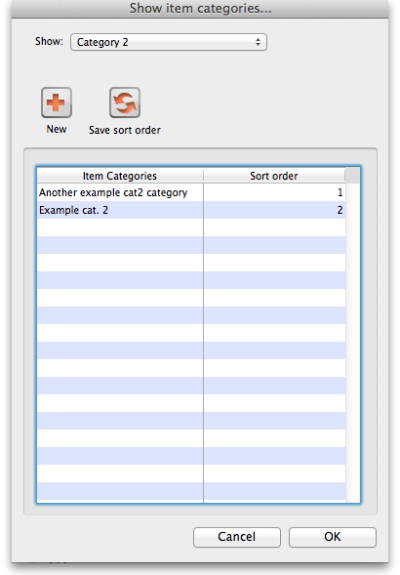

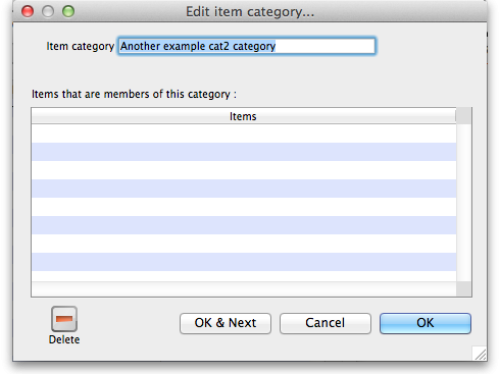

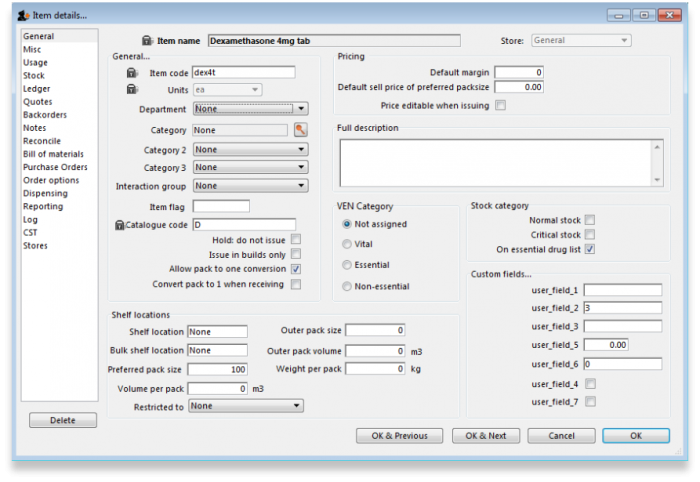

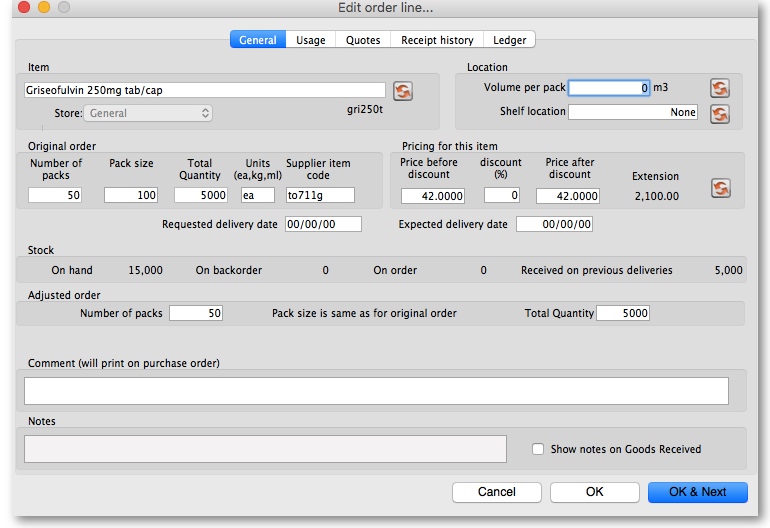

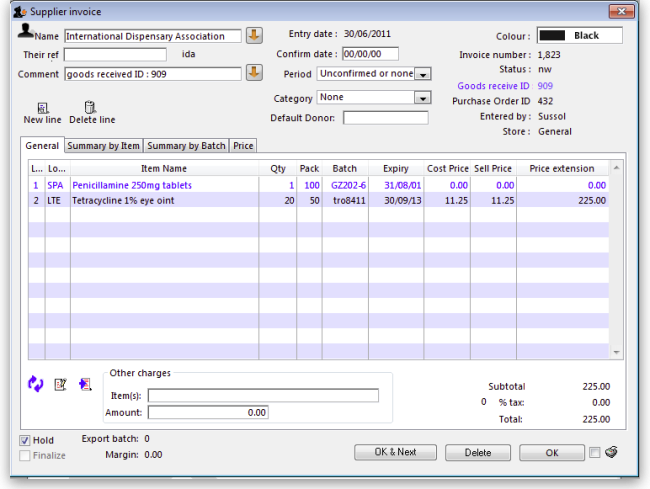

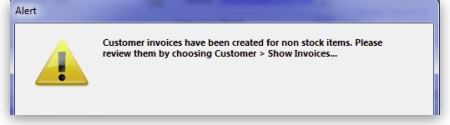

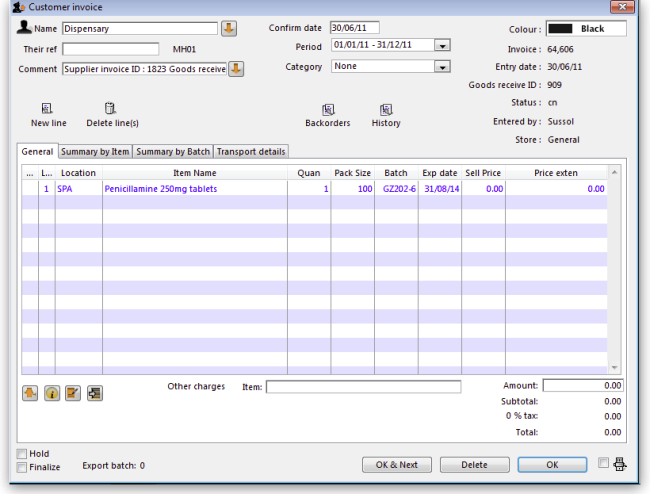

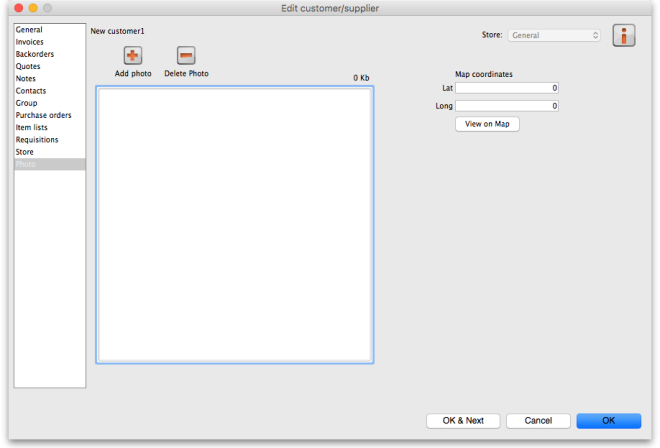

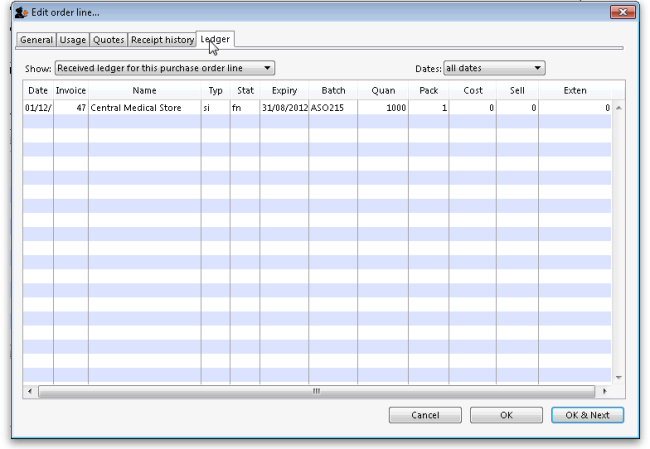

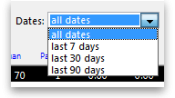

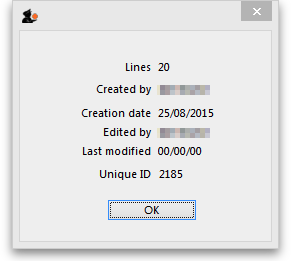

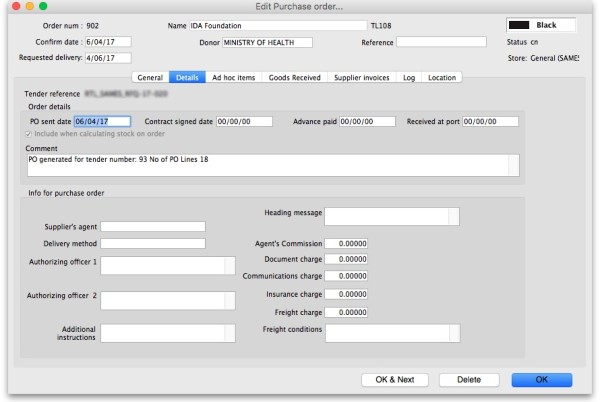

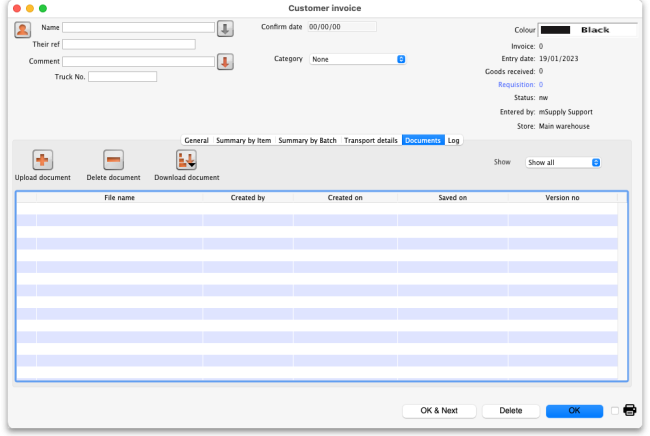

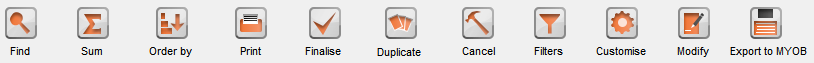

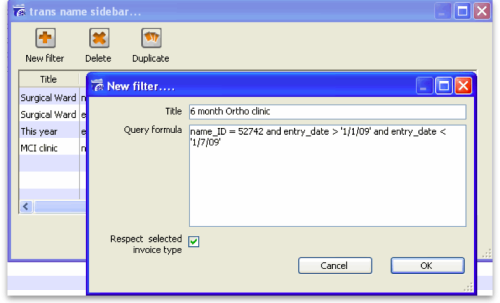

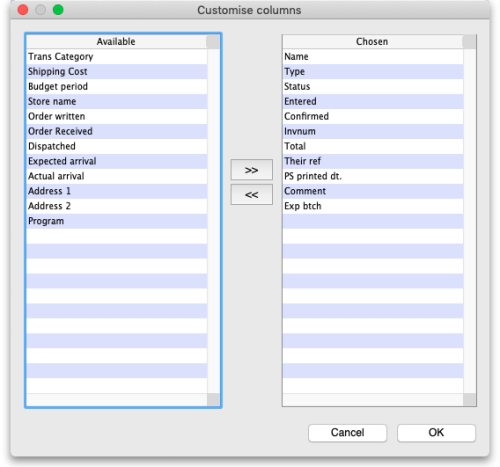

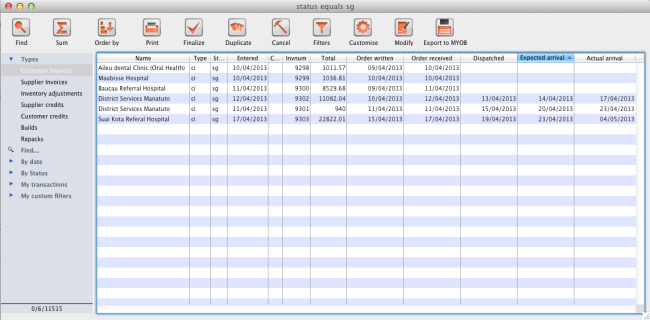

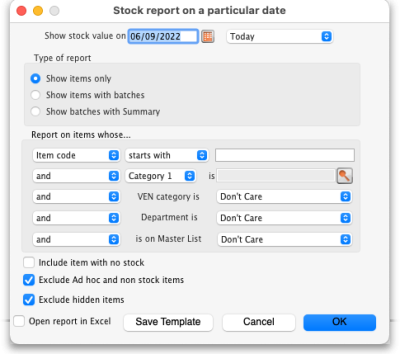

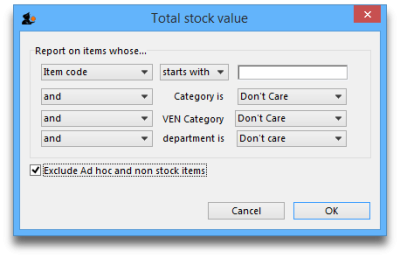

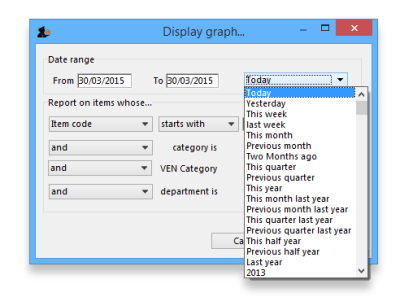

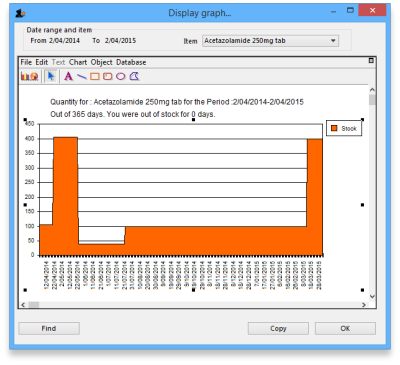

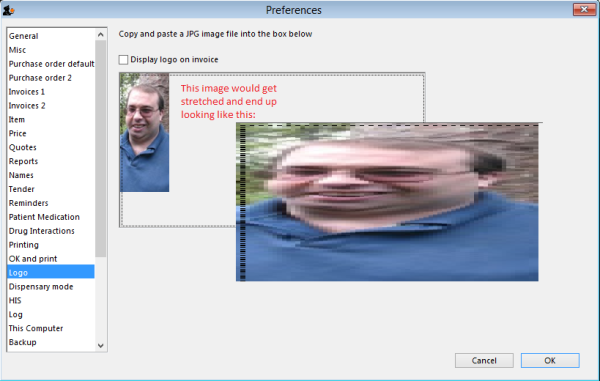

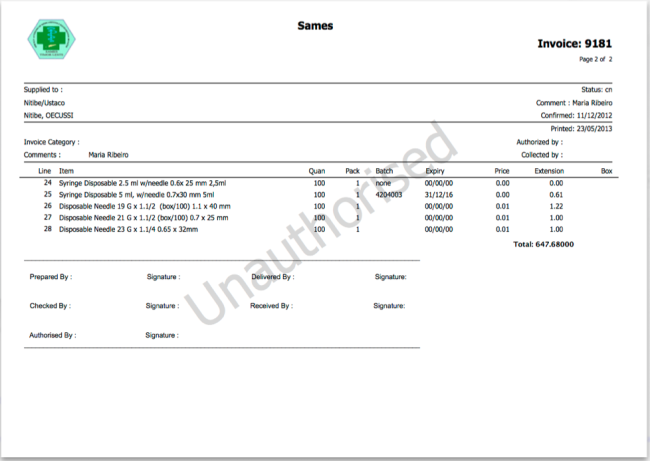

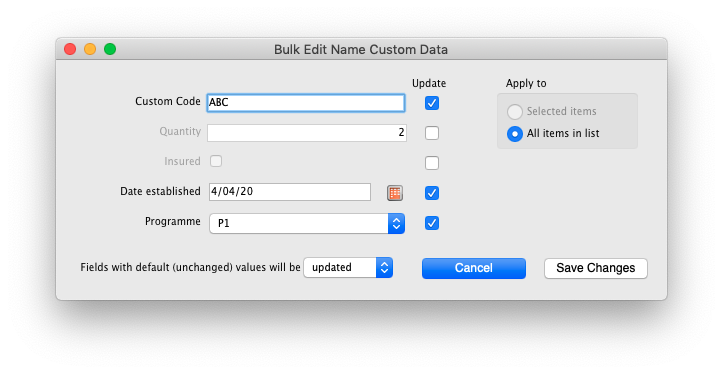

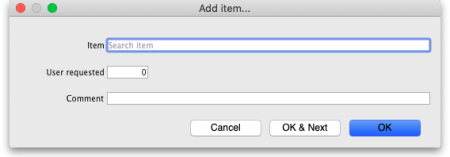

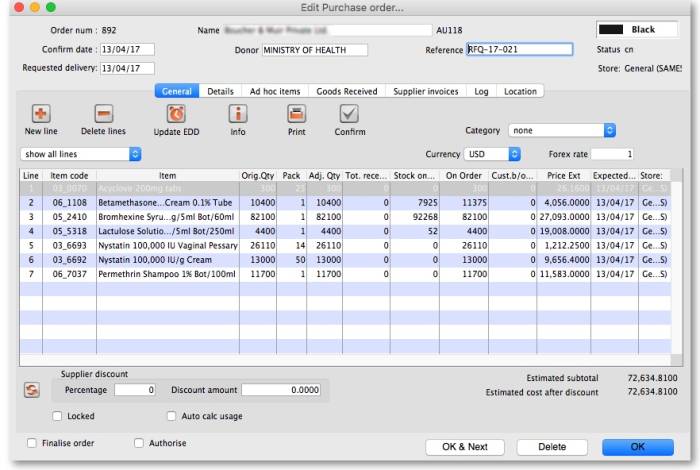

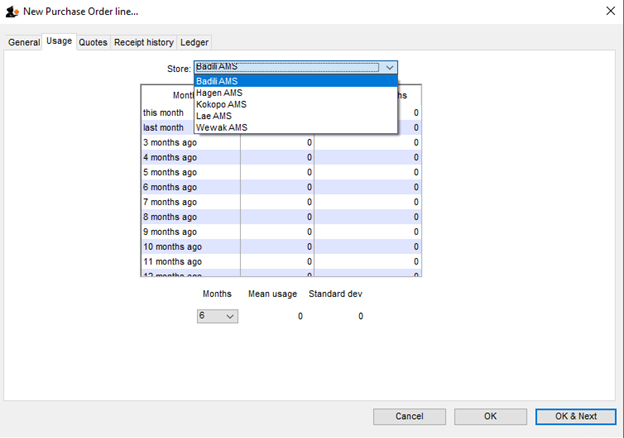

The software is under constant development as new features and facilities are added. We strive to ensure that the user guide and the graphics that it contains reflect these developments, but occasionally you may find that there are differences between the program itself and the guide or its graphics, where the updating of the guide has not quite kept pace with the development of the software. These are usually of a minor nature, but should you have any difficulties, do please send us an e-mail with details of your problem.

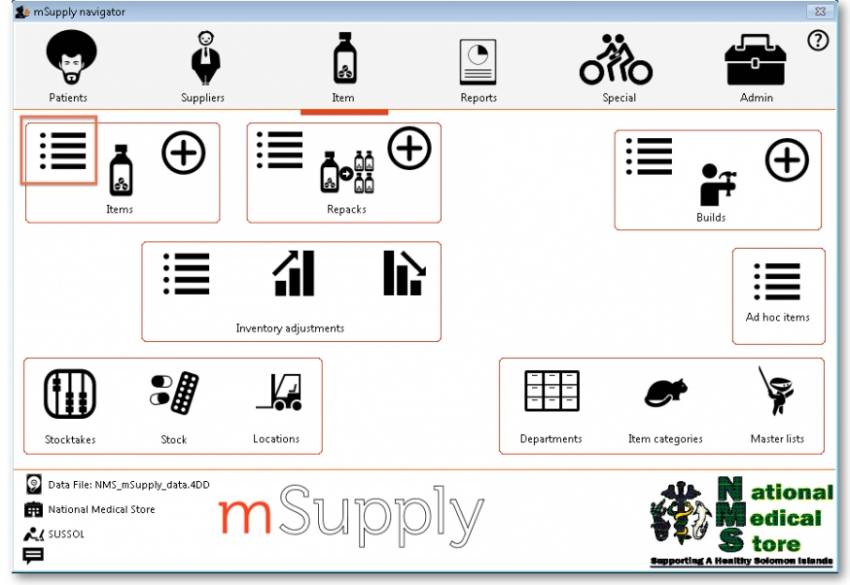

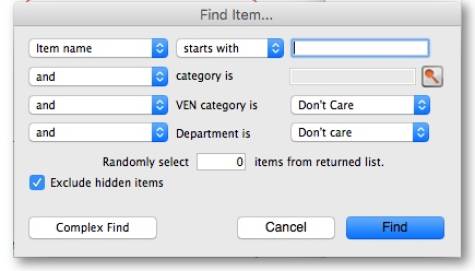

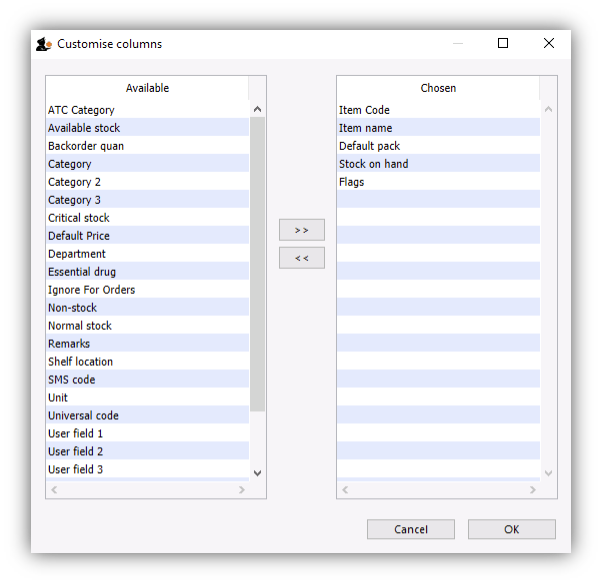

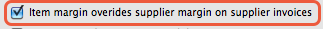

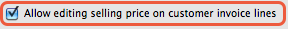

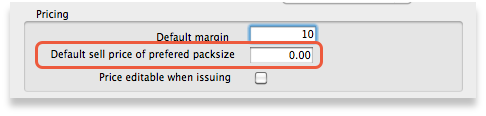

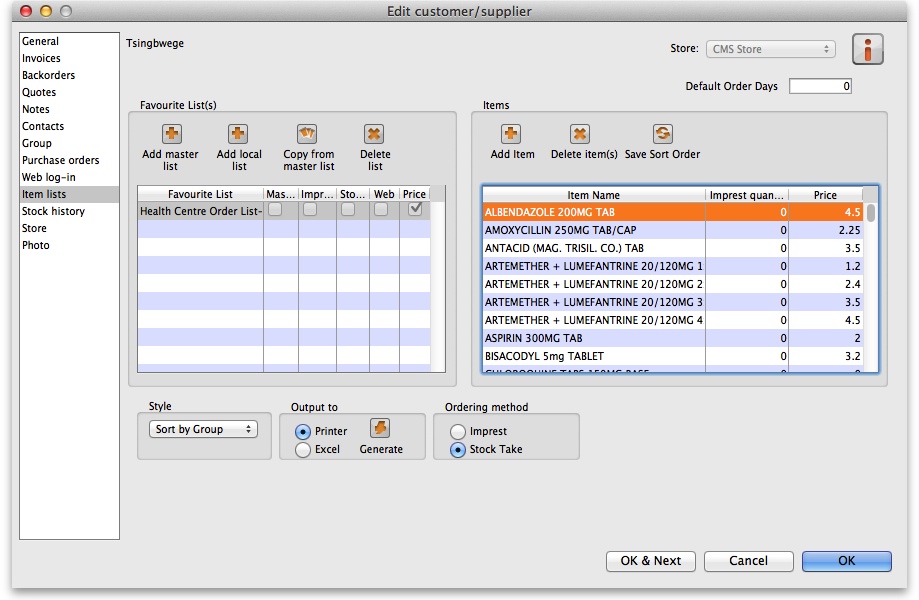

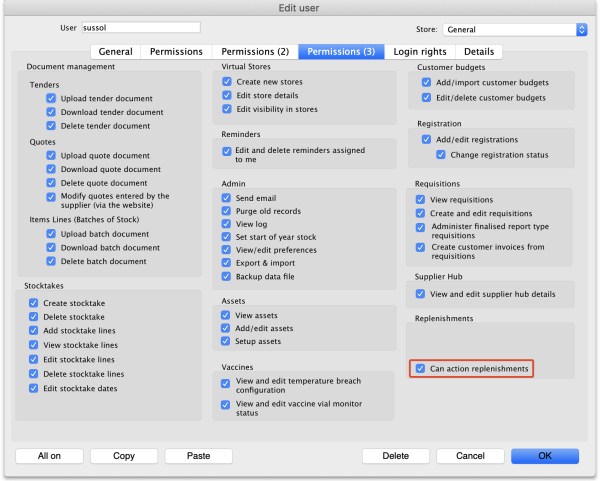

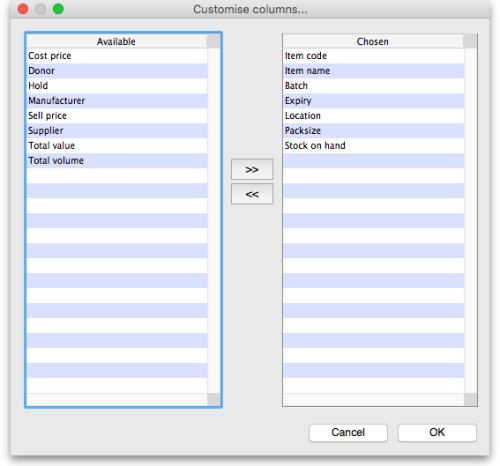

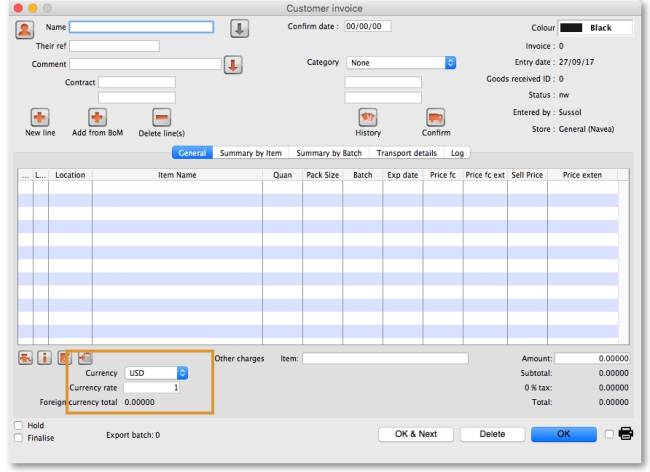

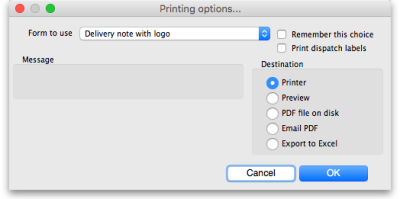

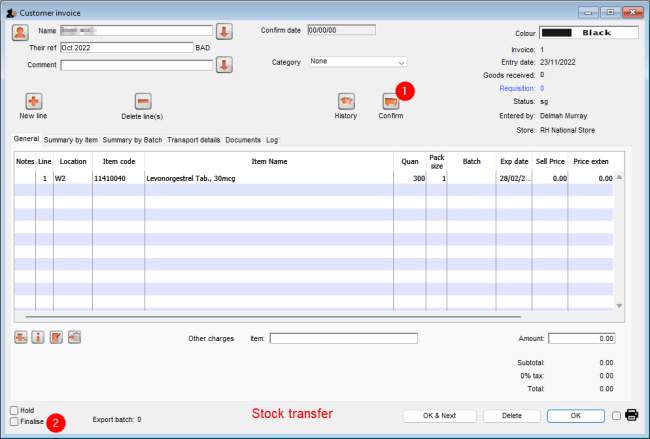

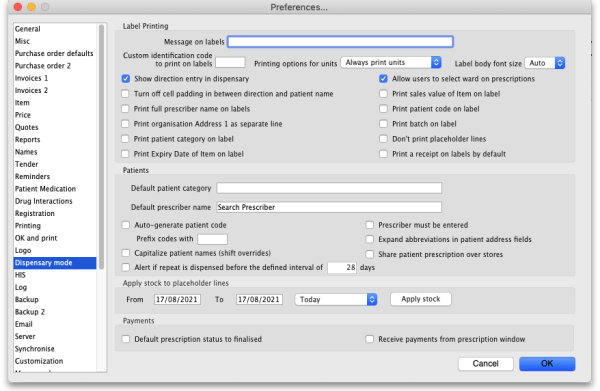

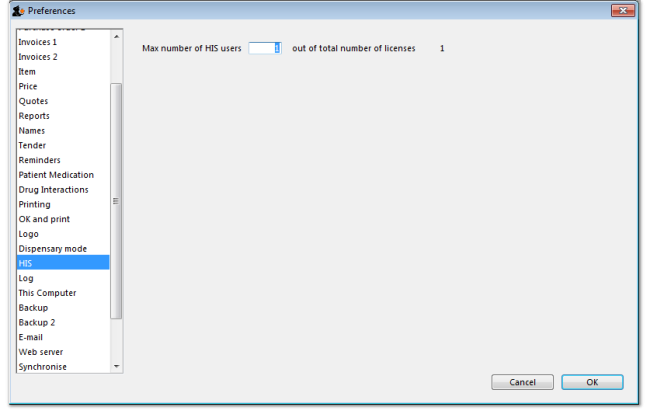

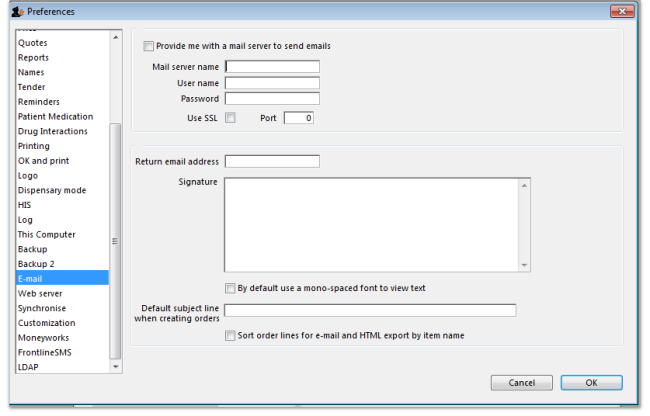

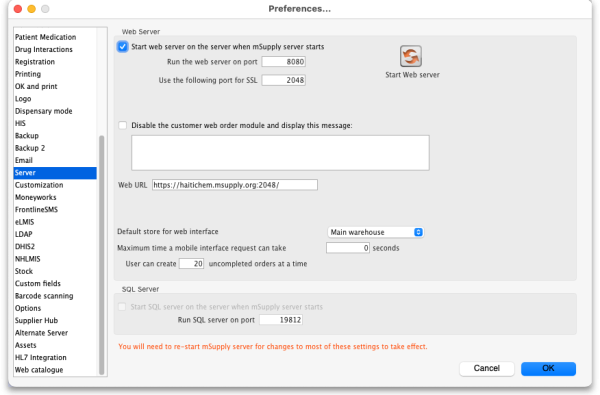

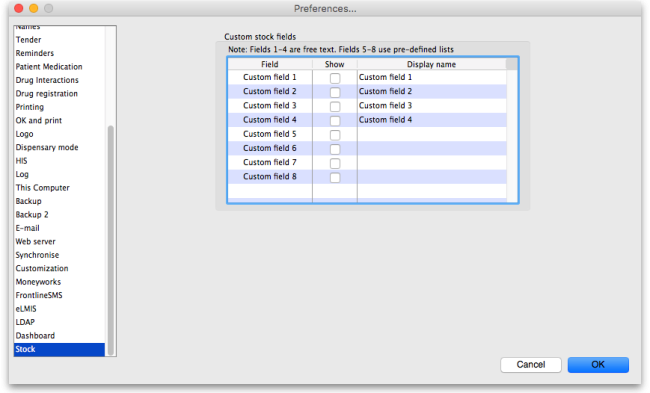

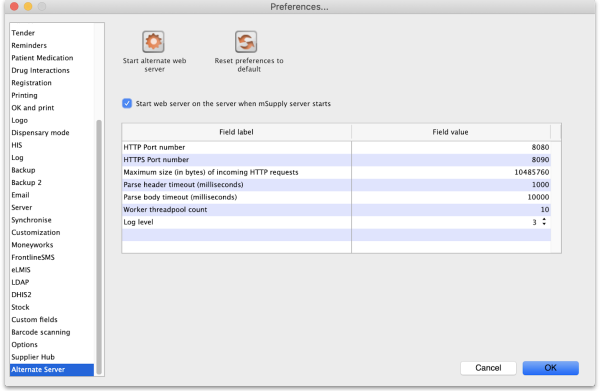

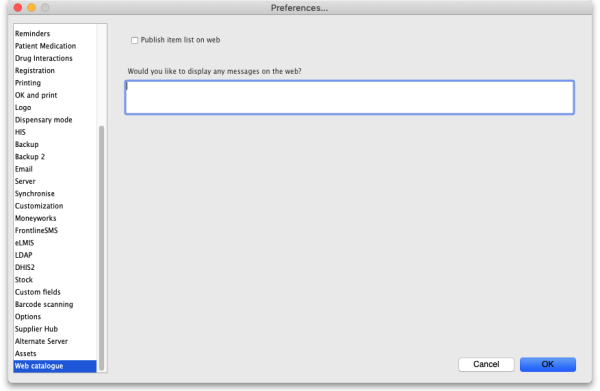

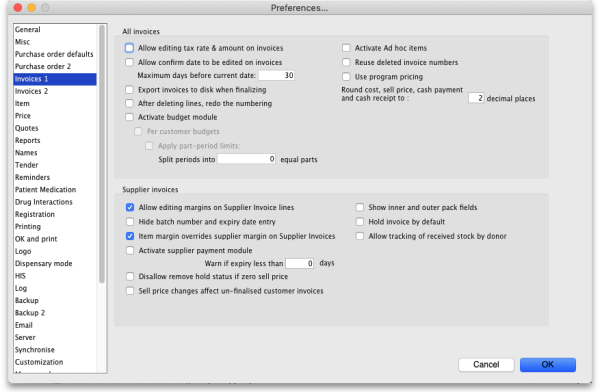

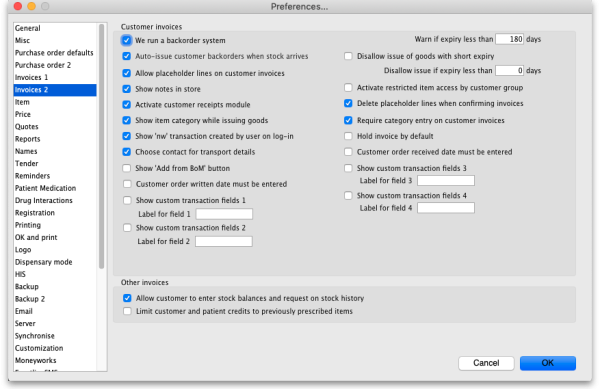

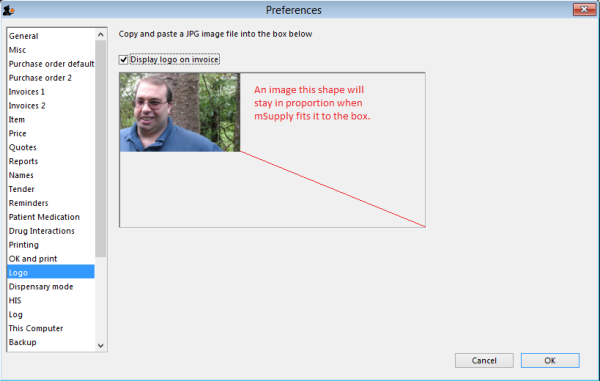

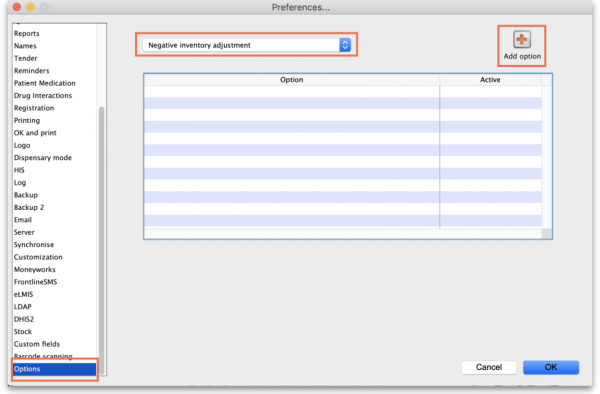

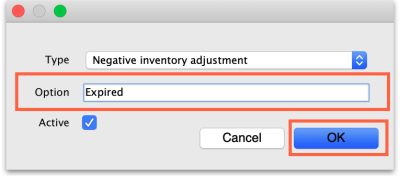

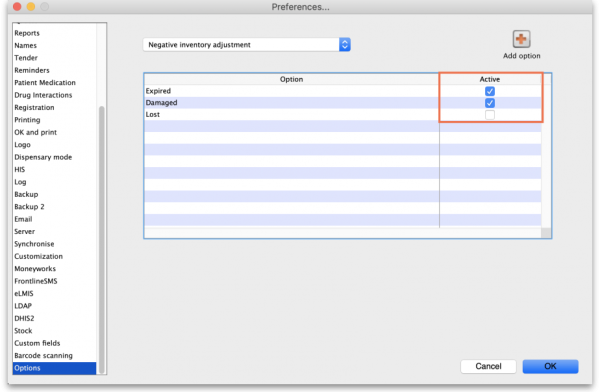

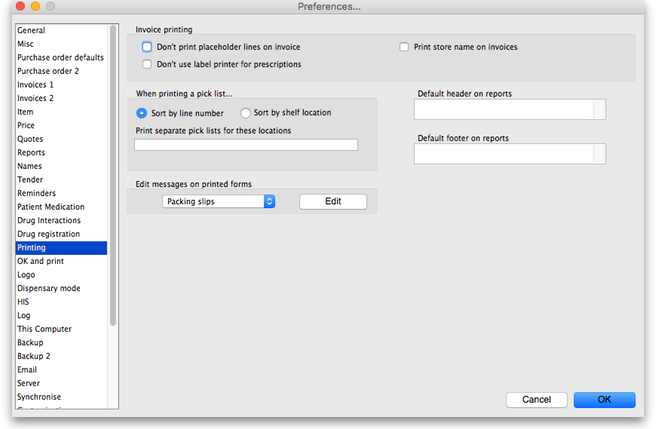

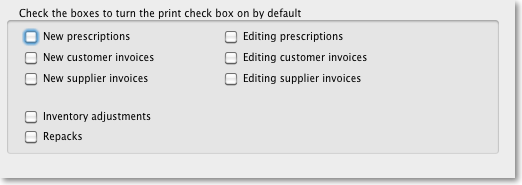

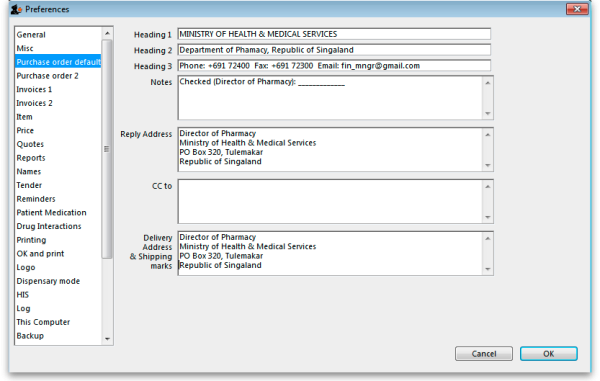

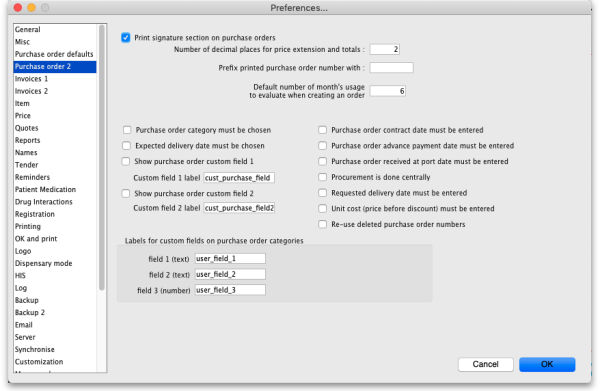

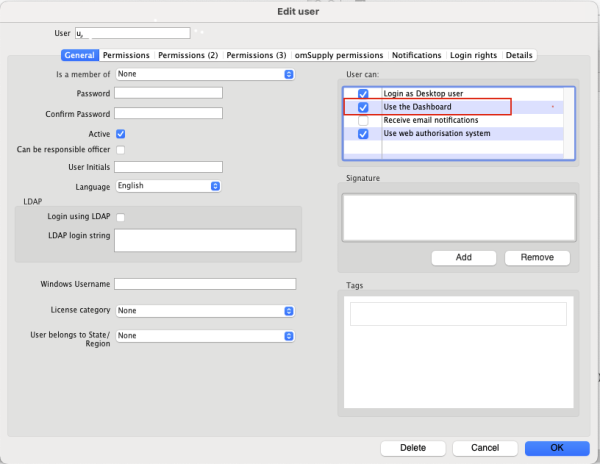

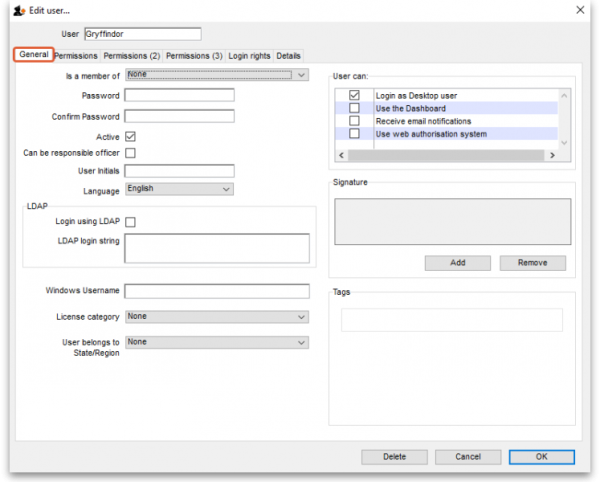

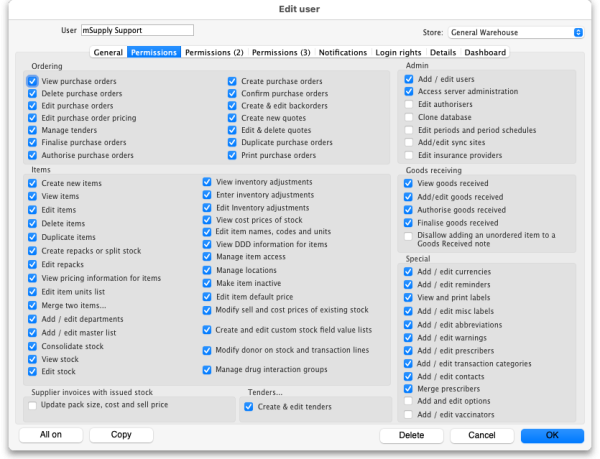

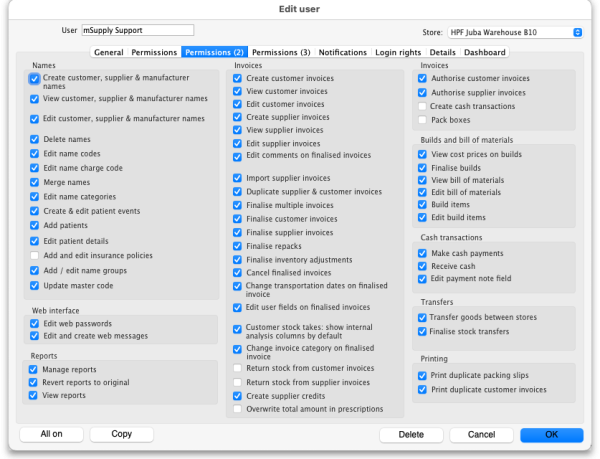

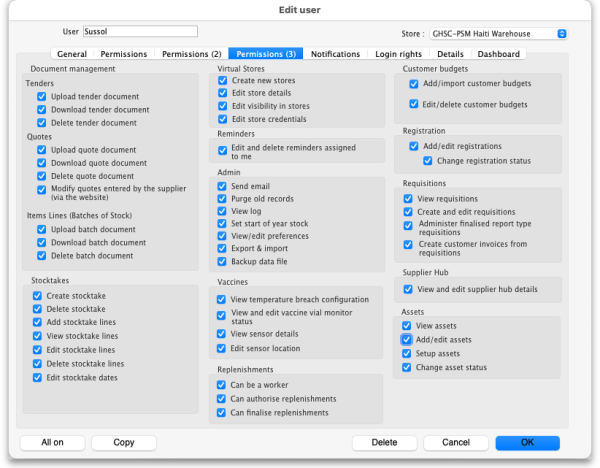

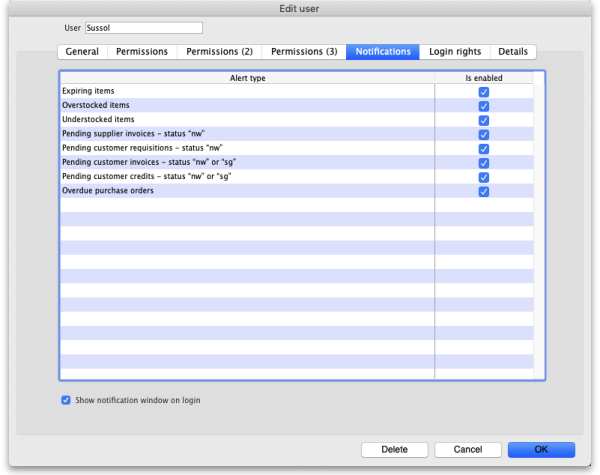

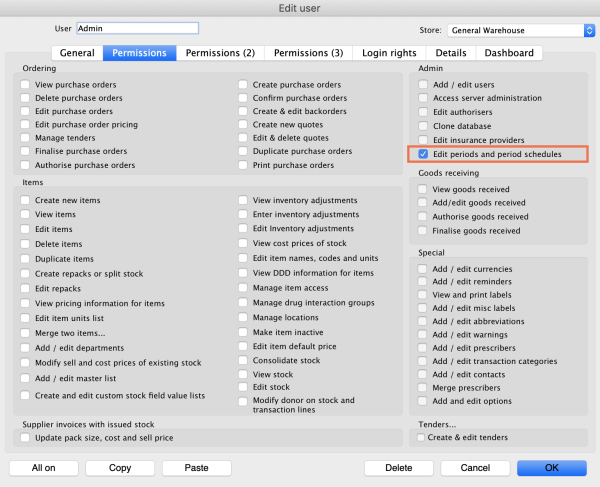

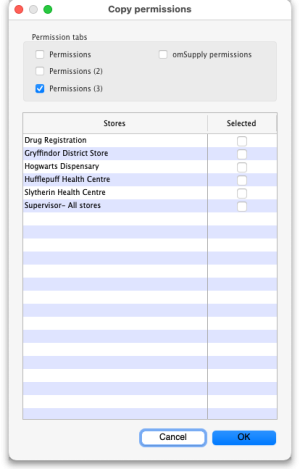

It should also be noted that with the considerable range of preferences and user permissions, a particular user's window may have features included or omitted (according to their preferences and their permissions) when compared with the screenshots appearing in the guide.

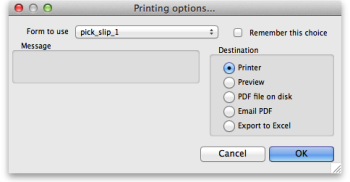

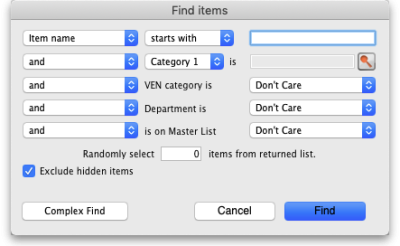

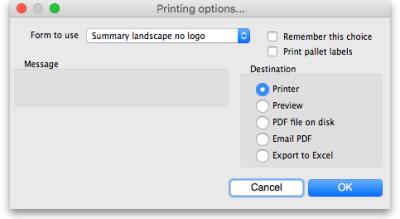

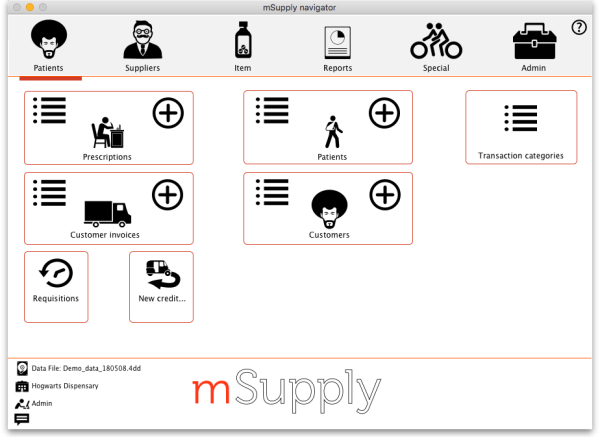

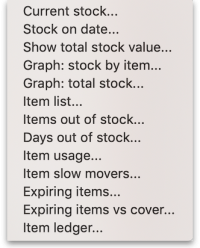

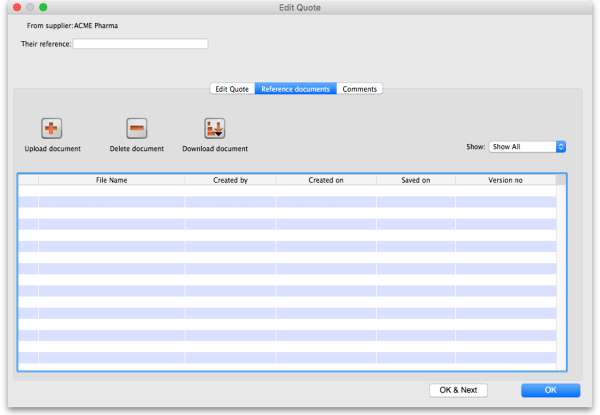

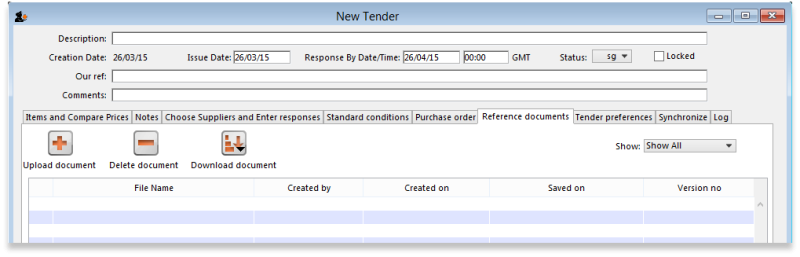

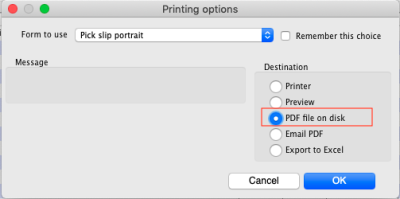

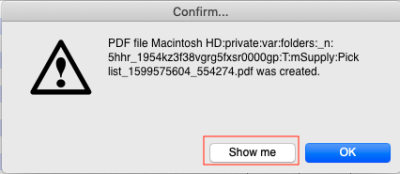

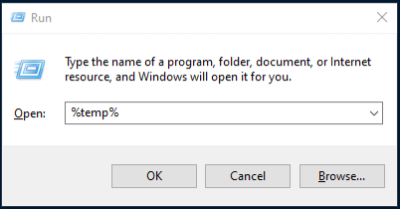

As mSupply is compatible with both Windows OS and Apple Mac OS, there is a mix of screenshots in the manual taken from each operating system.

About us

Sustainable Solutions was established in 2001 with the primary aim of supplying and supporting mSupply software in developing countries. We are committed to producing software that enables excellence in health care delivery. We take pride in looking after people who choose to use our services.

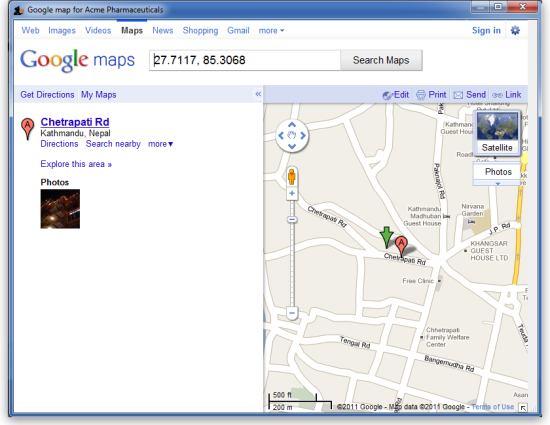

We have offices in:

- Kathmandu, Nepal

- Auckland, New Zealand

- Dundee, United Kingdom

- Belfast, United Kingdom

- Melbourne, Australia

We can be contacted at:

- email:info@msupply.org.nz

- phone: +977 1 5548021 (Nepal) or +64 225 190 499 (New Zealand)

Please feel free to request more information.

Thanks

- This software grew out of necessity at the Medical Supply Department, Kathmandu, Nepal. We learnt a lot from Jaap Zijp's software “Bhandari”, and from the staff at MSD where mSupply was originally developed and tested.

- Ujwal Khatry has stuck with Sustainable Solutions for twenty years, including the startup period where our company name could well have been a misnomer.

- Jim Staples of 4D inc. http://www.4D.com kindly arranged an initial donation of the 4D development environment we use.

- Thanks to those people in the 4D tech mailing list who have helped for no benefit to themselves.

- John Ross, Pharmacist of Patan Hospital, Kathmandu, believed in the quality of mSupply enough to use it long before it was fully ready

- David Adams kindly donated his superb texts on 4D.

- The moderators of the E-Drug mailing list have been gracious in letting us use that list for occasional announcements.

- Juliet has always been supporting and more through the ups and downs of starting a new organisation.

Copyright

mSupply software is copyright Sustainable Solutions, 2006, UMN/INF/Interserve 1996 to 1999. You may only use the software in accordance with the accompanying licence agreement.

Licence Agreement and Costs

Commercial users or any user wanting multi-user functionality enabled must obtain a licence from Sustainable Solutions.

Please view our web site http://www.msupply.org.nz for up-to-date pricing.

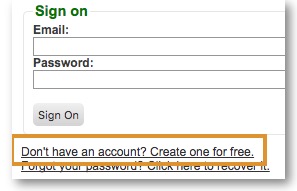

A free version of mSupply is available for Non-commercial use

- You may use mSupply software in single user mode for free as long as it is used:

- in an approved not-for-profit organisation

- in a developing country.

- Sustainable Solutions shall be the sole arbiter of those qualifying for free use.

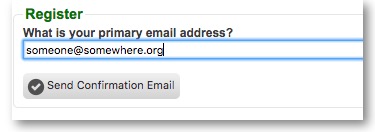

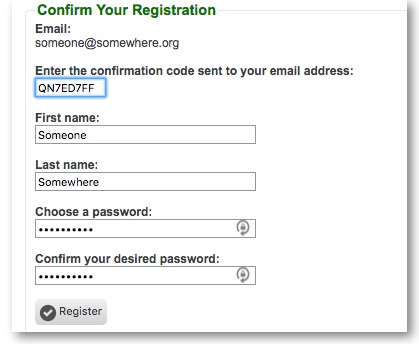

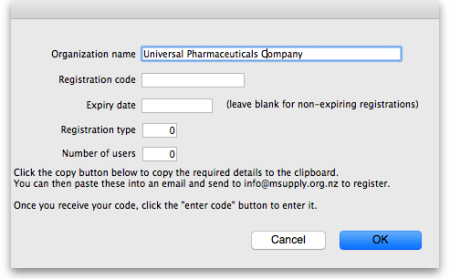

- All users (free and paid) must register with Sustainable Solutions to obtain a registration code. Information supplied will not be used for any purpose other than generation of registration code.

- Users who have obtained a free licence number are not eligible for free support.

Please contact us for quotes regarding customised versions and installation and training packages.

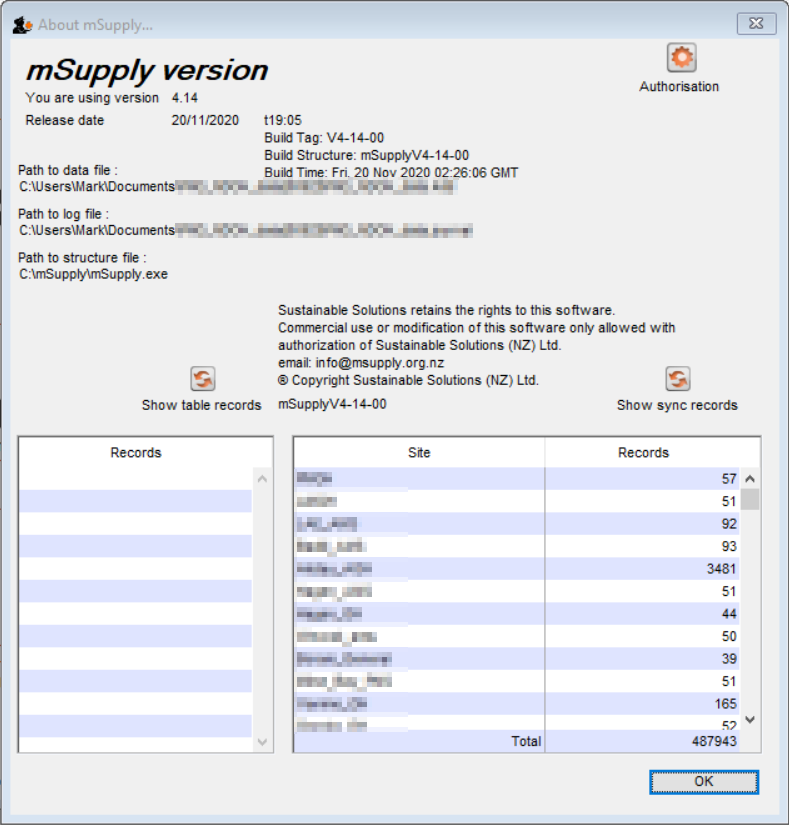

Changes in recent versions

The mSupply version history is available here: http://msupply.org.nz/history

| Previous: 1. About mSupply | | Next: 1.02. Why mSupply? |

1.05. Terms, definitions and conventions used in this user guide

If you aren't familiar with using a computer, you should read this chapter. We also recommend you work through the 3. Tutorial section of this user guide.

General terms

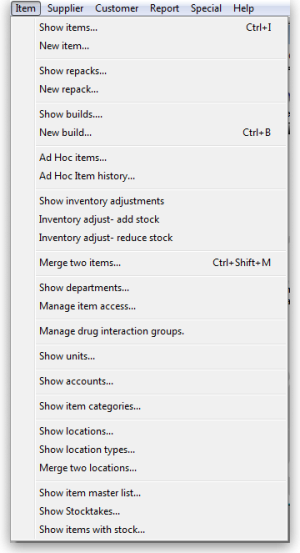

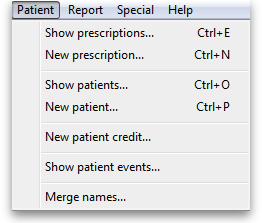

Menus: choose New item from the Item menu (sometimes also written as choose Item>New item) means click on the word Item in the menu bar, then choose New item from the menu that drops down.

Keyboard keys: a handful of keys on the keyboard are used extensively and are indicated in italics. The most common are: Tab, Shift, Ctrl, Alt, Enter and Backspace.

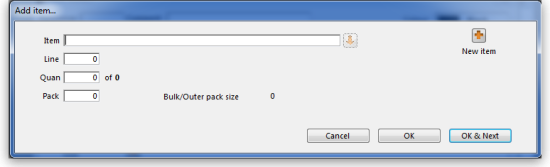

Field: an area on the screen (usually a white box) where you can make an entry, either text or numbers. In many places, you can use your mouse to hover over a field for a description of what is required.

Typed data: anything that must be typed into a field is shown in monospace font. For example: Type 100 and press Enter.

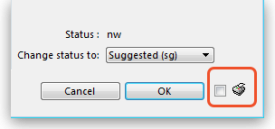

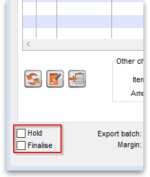

Checkbox: a box that changes from having an “X” in it to being blank each time you click in it. To “check” a checkbox means to click it so that an “X” appears (if there is not one already present). Checkboxes have text beside them explaining what the box is for.

Tab & Shift: you can generally move from field to field in a window using the Tab key. Holding down the Shift key while pressing the Tab key will move from field to field in the reverse order to normal. Note that on Windows, some buttons are “tab-able”. That is, pressing the Tab key moves the “focus” to a button. Pressing the Return or Enter key will then activate that button.

Highlight button: pressing the Enter key will operate the highlighted button in a window. This is is usually the OK button.

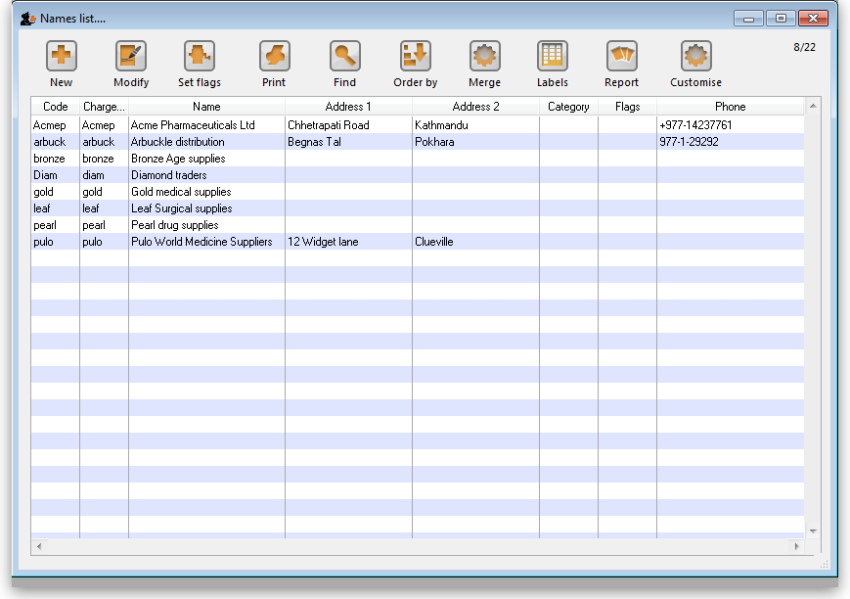

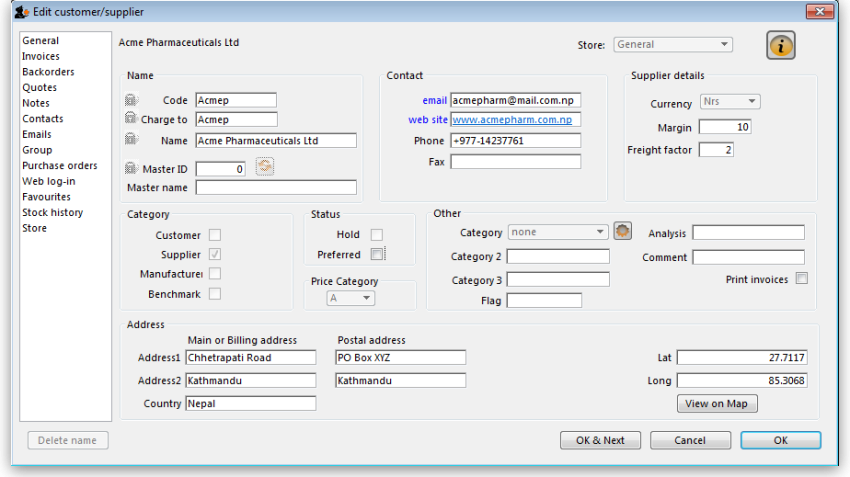

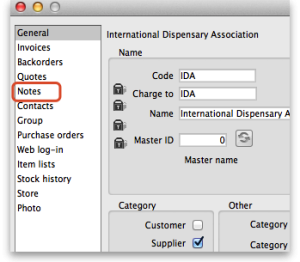

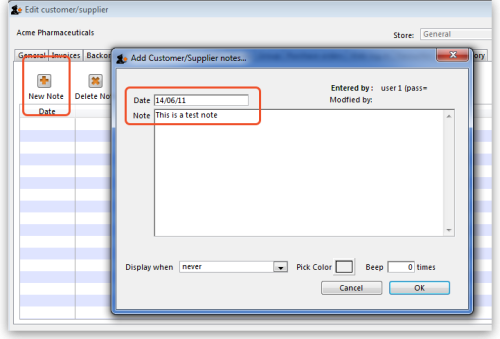

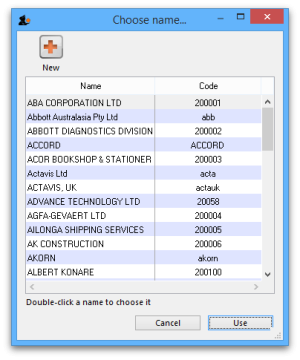

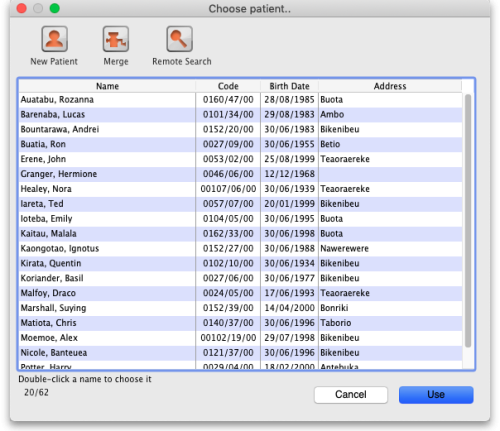

Double-click: in lists (e.g. of suppliers, customers or items), double-click using the left button of the mouse on a line to edit or view more details.

Insertion point: the blinking line in a field that indicates which field is currently accepting typed input.

OK button: can be operated by pressing the Enter key.

Cancel button: can be operated by holding down Ctrl key (cmd on Macs), and pressing the period key (full stop).

Path to a file (or document): a way of describing where a document is stored on your hard disk. It is written as hard disk:folder 1:folder 2:document, which is the same as C:\folder 1\folder 2\document.

Modifier keys: are different for Windows and Macs. We've tried to list both in the manual, but sometimes one might slip through.

- The Windows Ctrl (control) key does the same as the cmd (command) key on Macs

- The Windows Alt (alternate) key does the same as the opt (option) key on Macs.

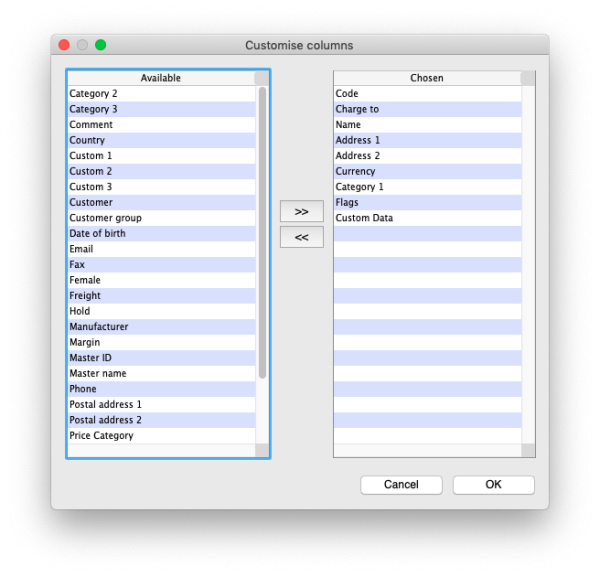

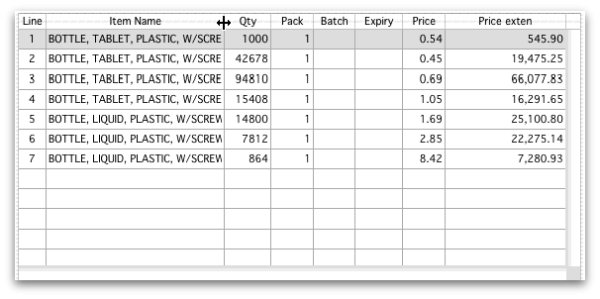

Column headings: can be clicked to sort the list by that column.

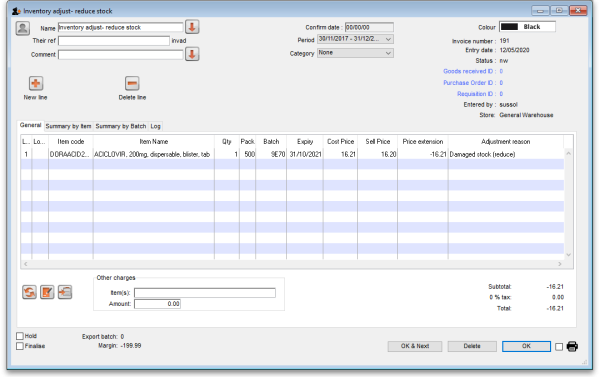

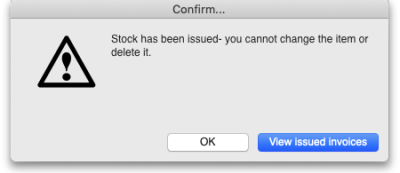

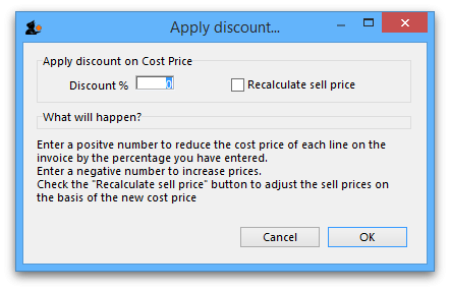

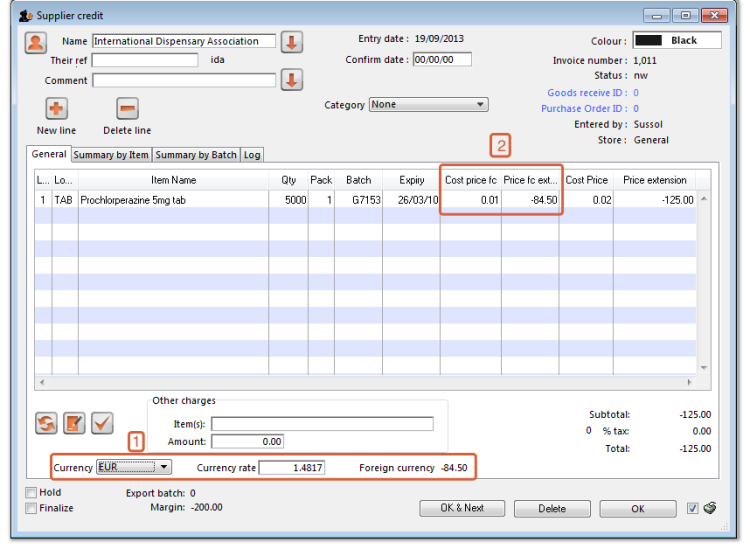

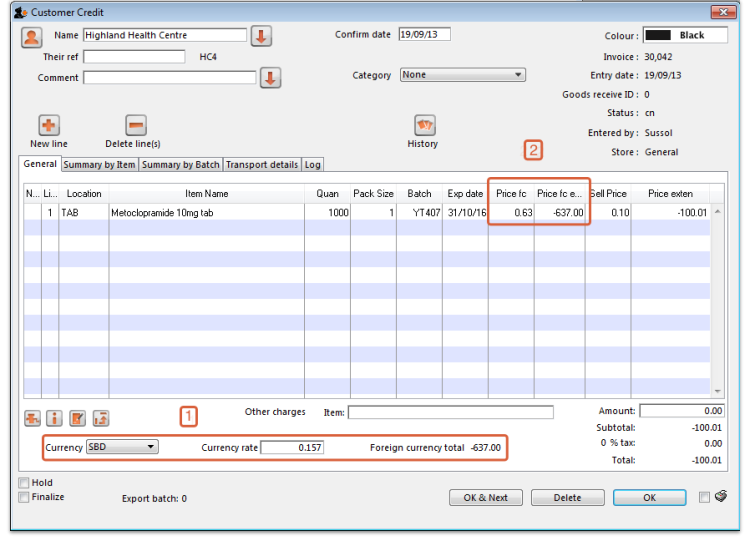

Negative values: are generally not required in mSupply. Even when you are entering returned goods from customers, or returned goods to suppliers, you enter positive values. mSupply automatically converts the invoice total to a negative amount when it is a credit to a supplier or from a customer.

mSupply terms

Basics

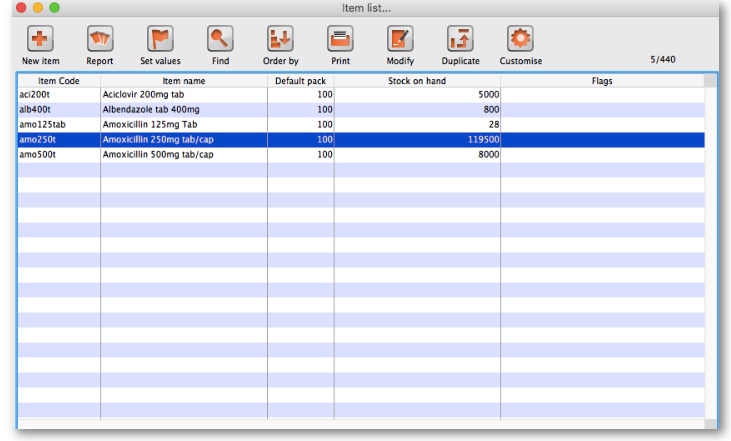

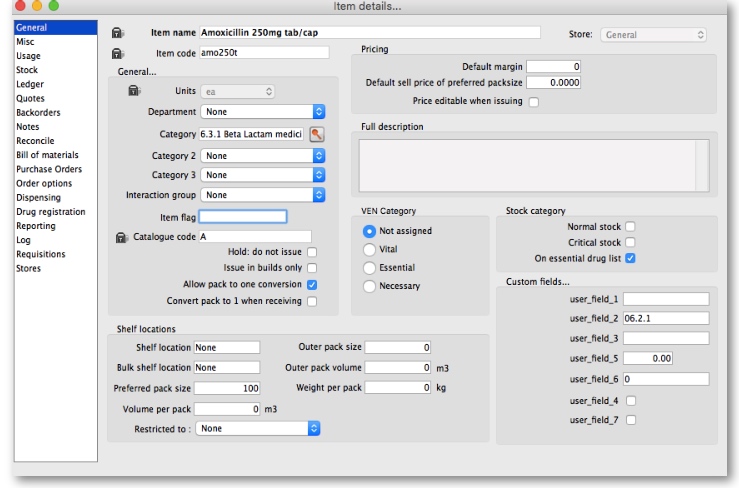

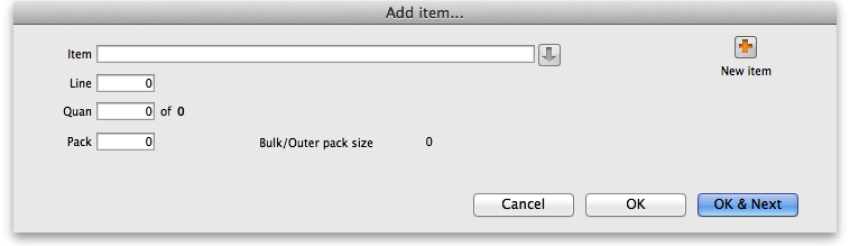

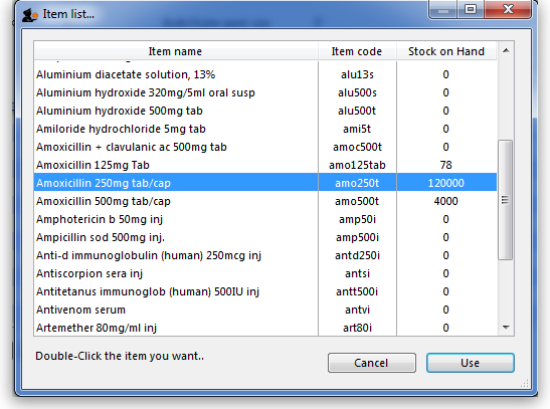

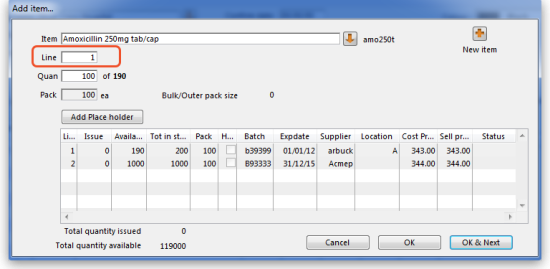

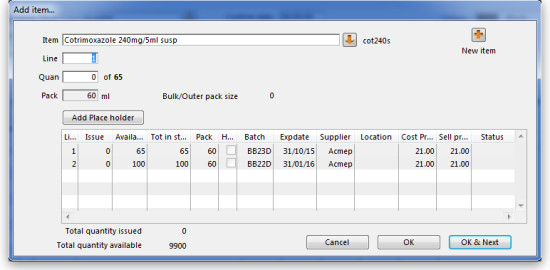

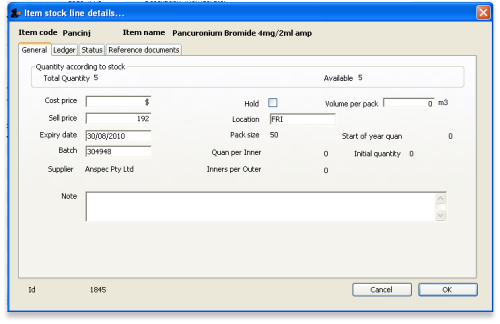

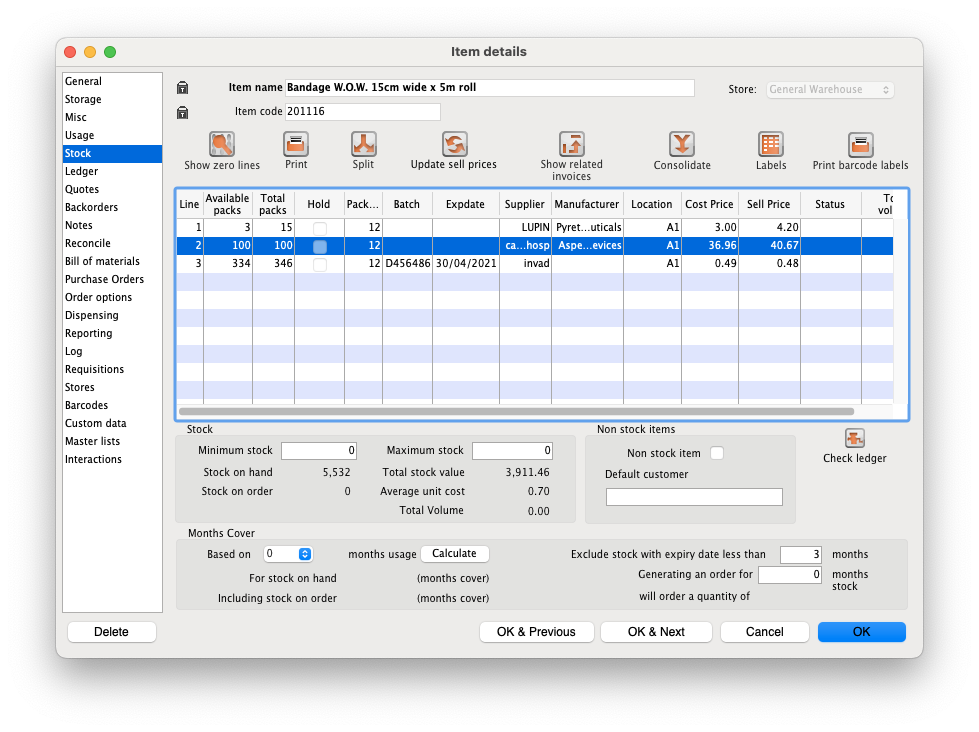

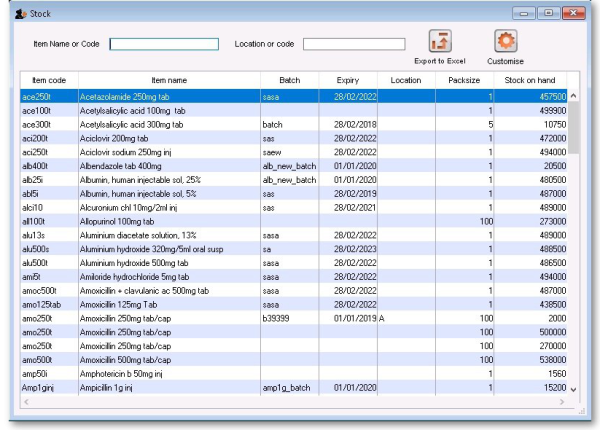

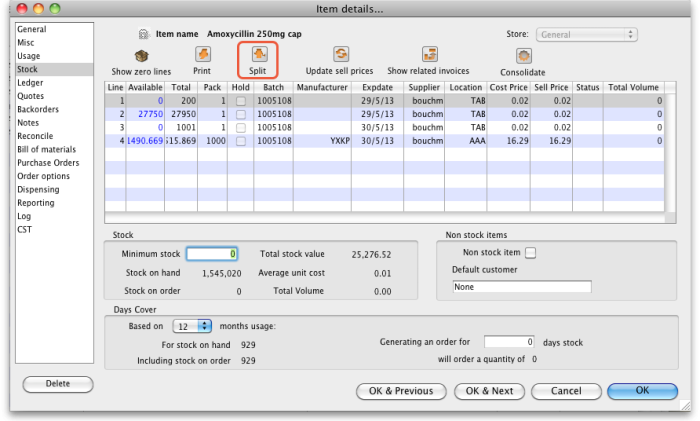

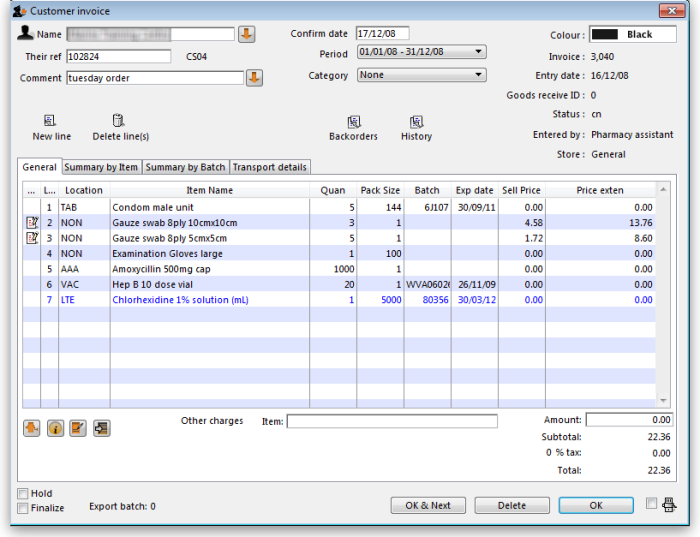

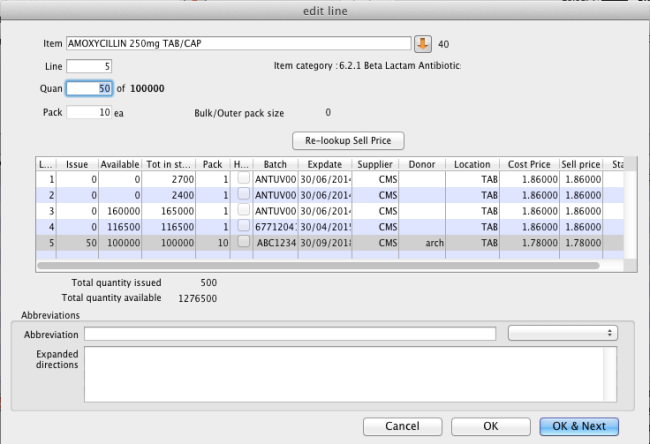

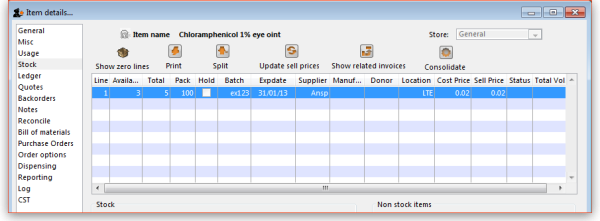

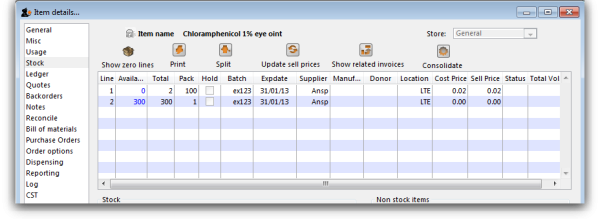

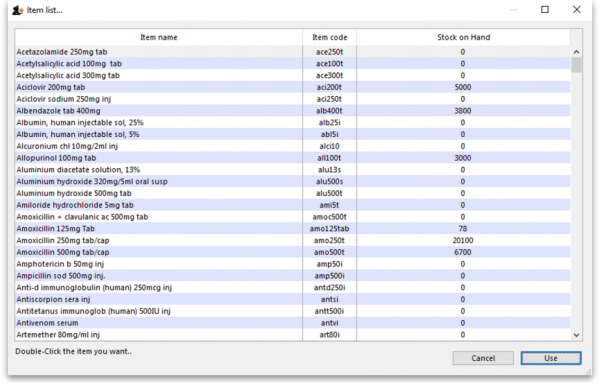

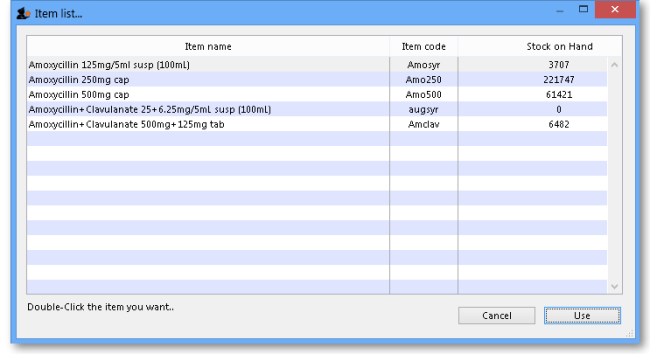

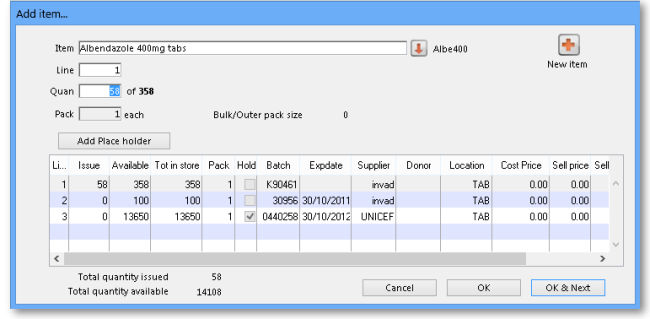

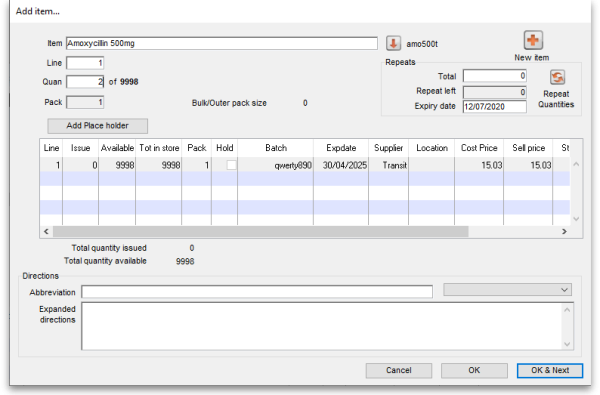

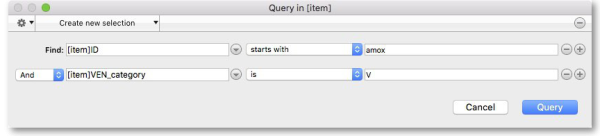

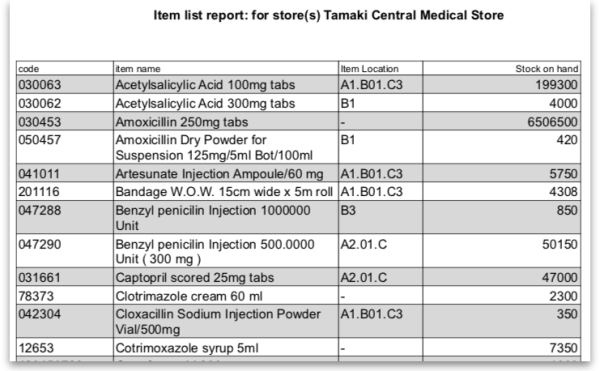

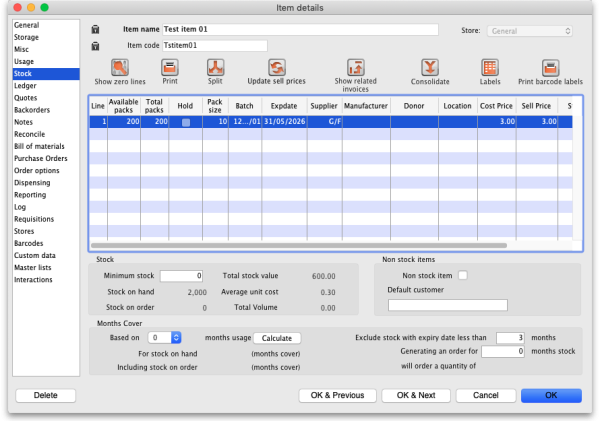

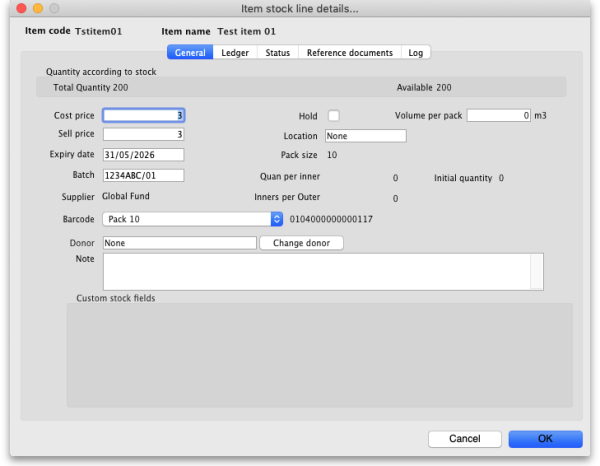

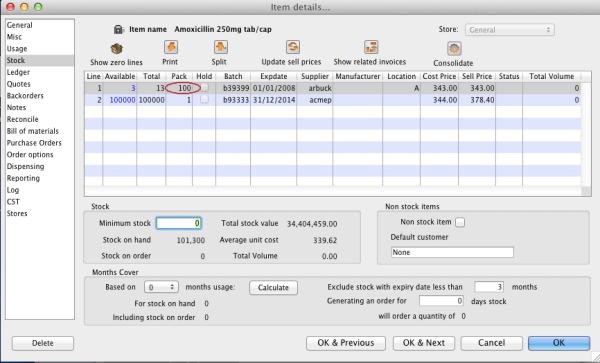

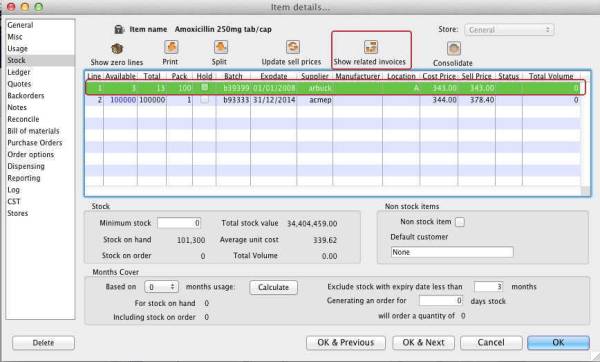

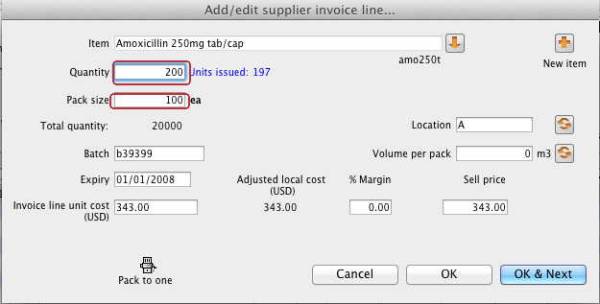

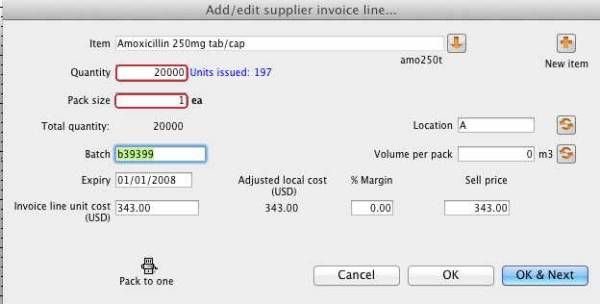

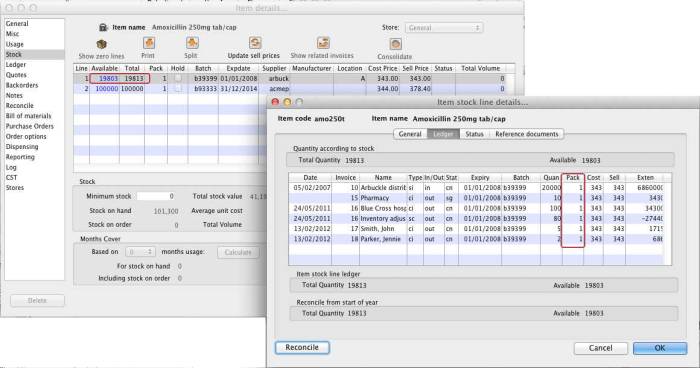

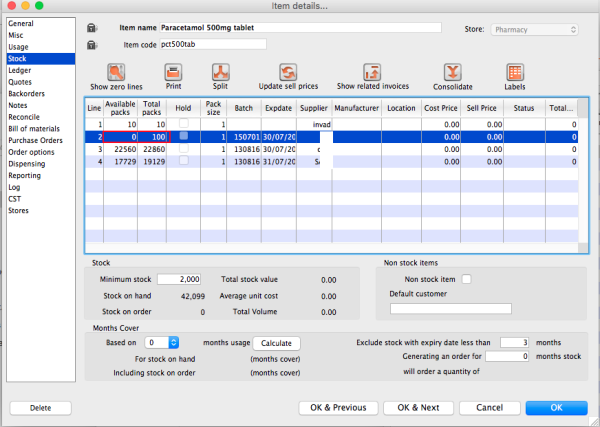

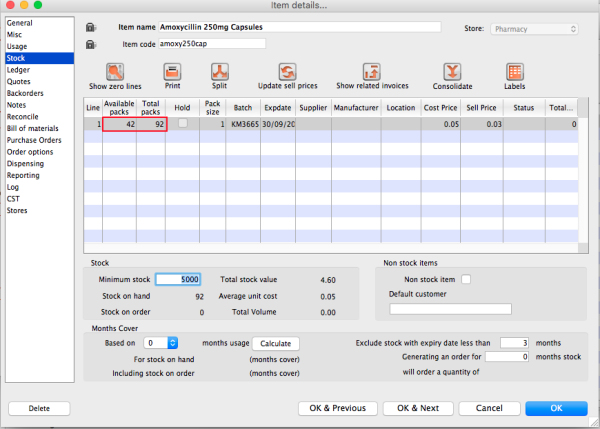

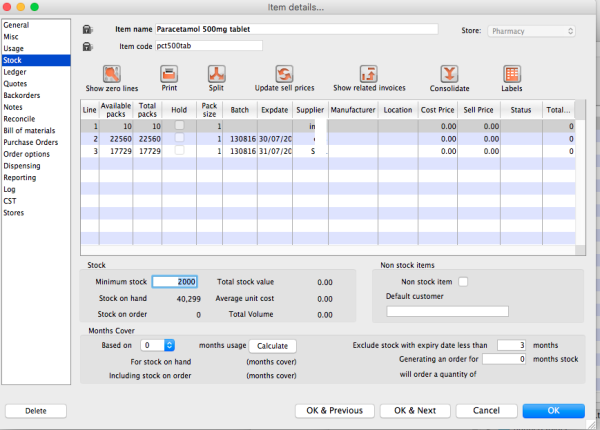

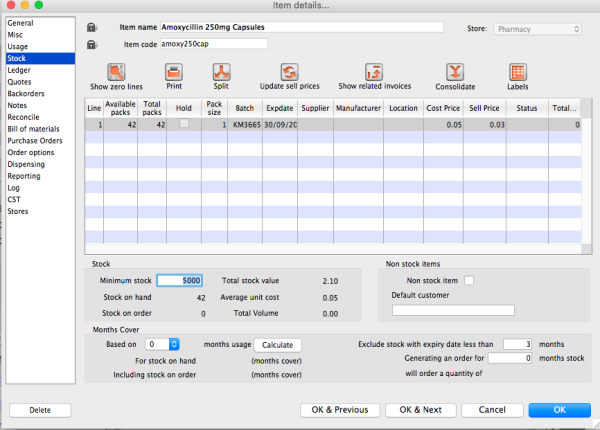

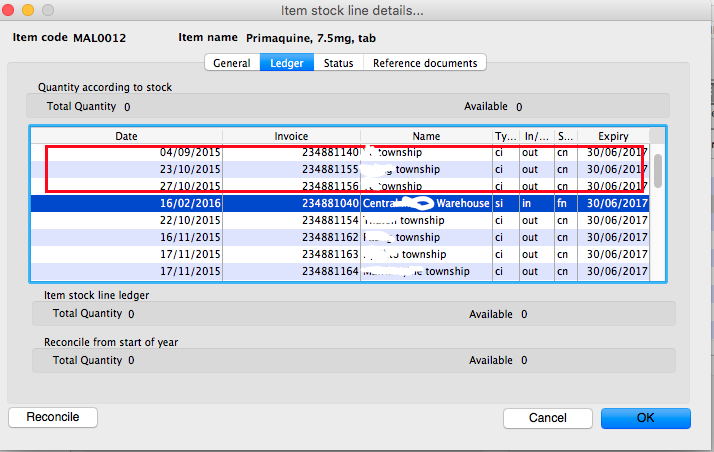

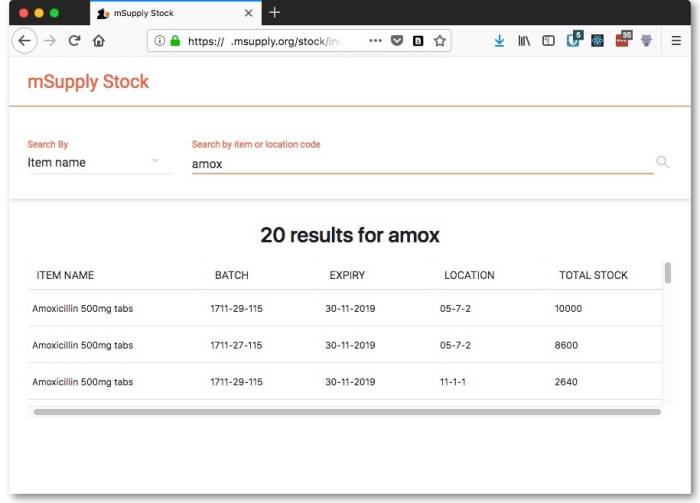

Items: Items are the products we manage in mSupply, including medicines, consumables, equipment, laboratory and radiology items or even larger assets such as vehicles and furniture. An item may or may not have stock lines at any given time. For example: In the example data file provided with mSupply, “Amoxycillin 250mg tab/cap” is an item. When you first start to use the example data file it has 2 stock lines. (You can view them under the “stock” tab of the Item details window (more on that later!).

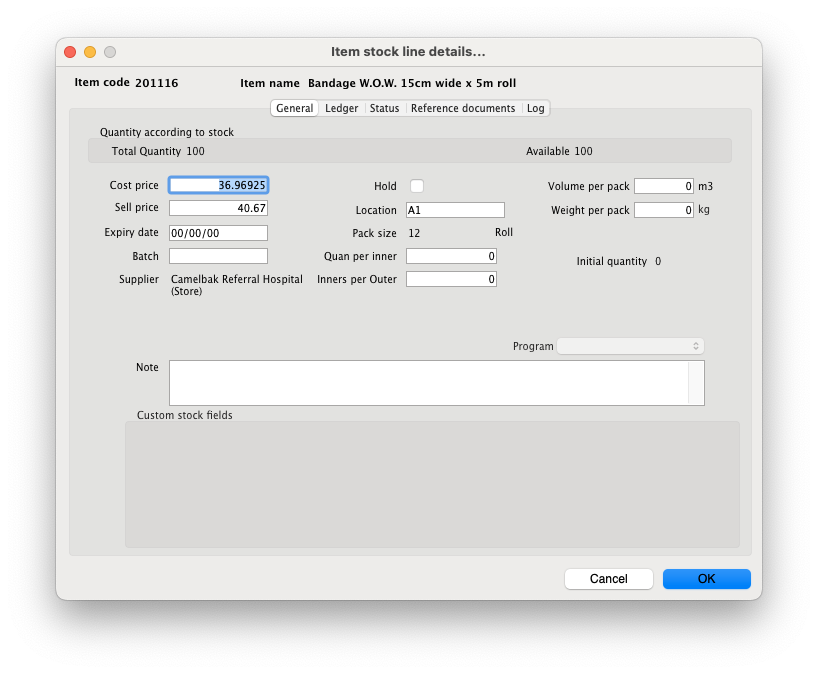

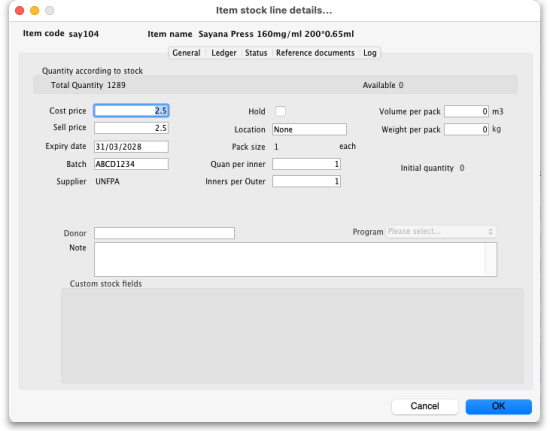

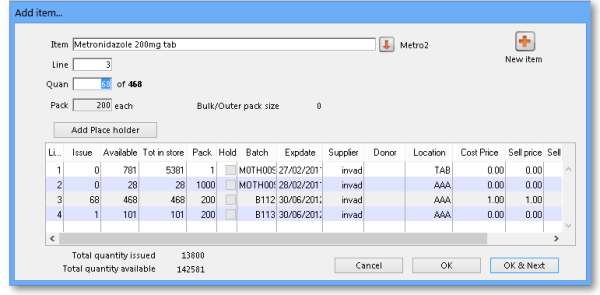

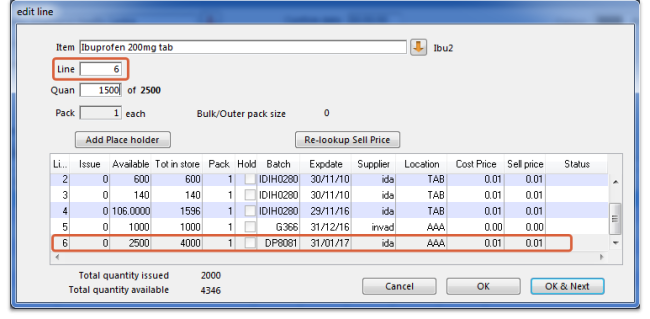

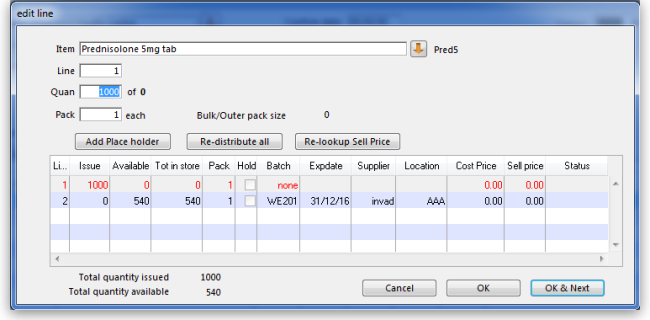

Item Lines (or “Stock Lines”): Represent different batches of the same item.

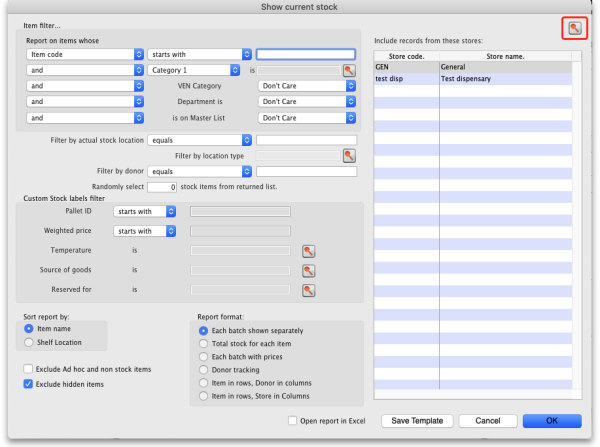

Stock: Represents the physical stock (inventory) in your store.

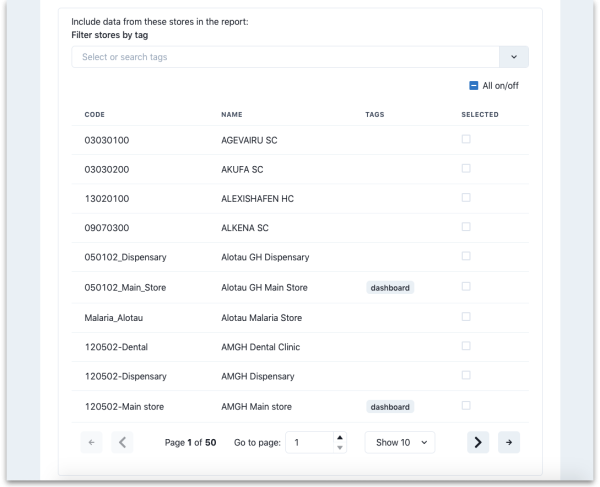

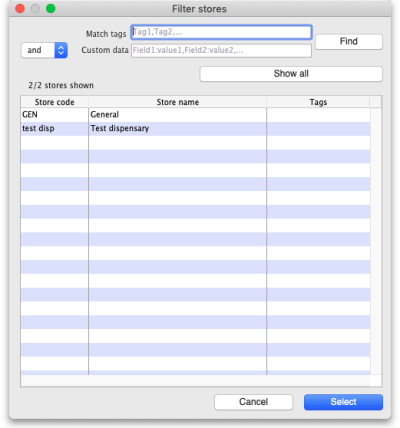

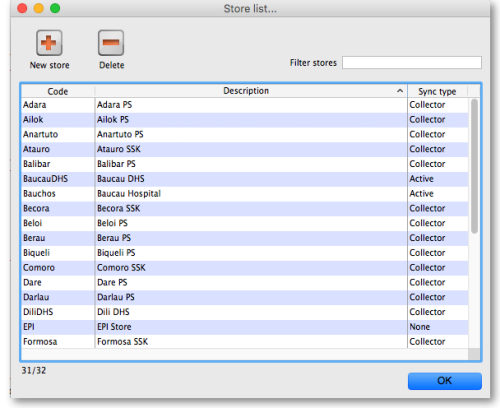

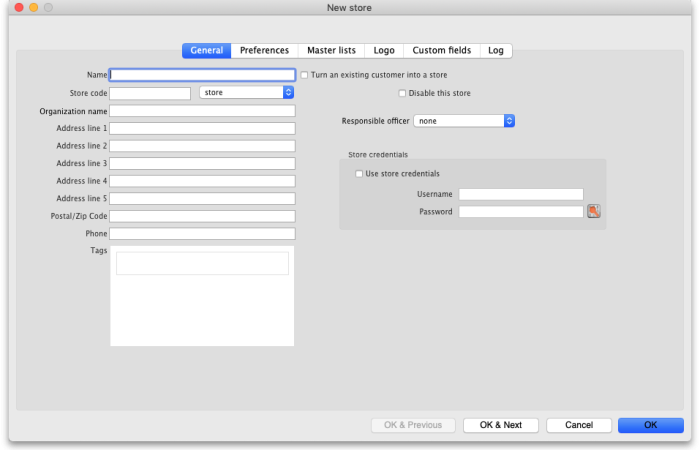

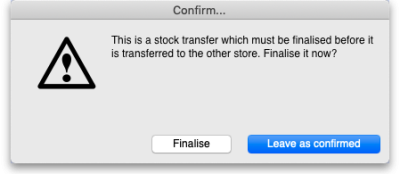

Stores: Stores are facilities using mSupply (desktop or mobile). Some facilities can run multiple stores. For example, there may be a pharmacy in the emergency department that manages stock completely separately to the main pharmacy – this can be a separate store (if they are using mSupply).

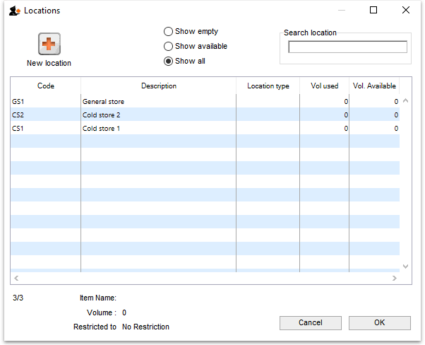

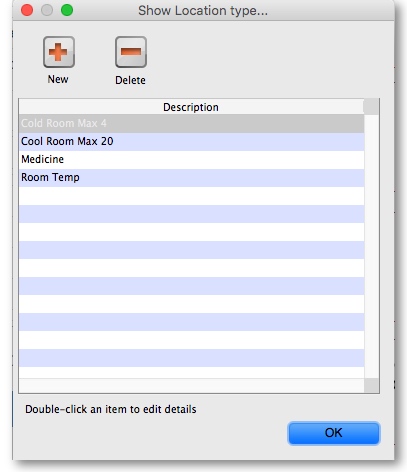

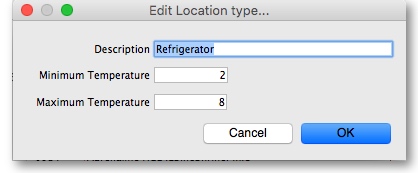

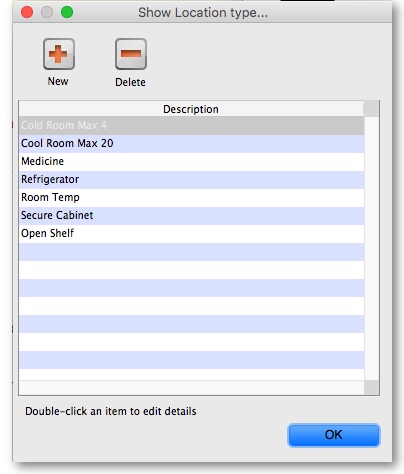

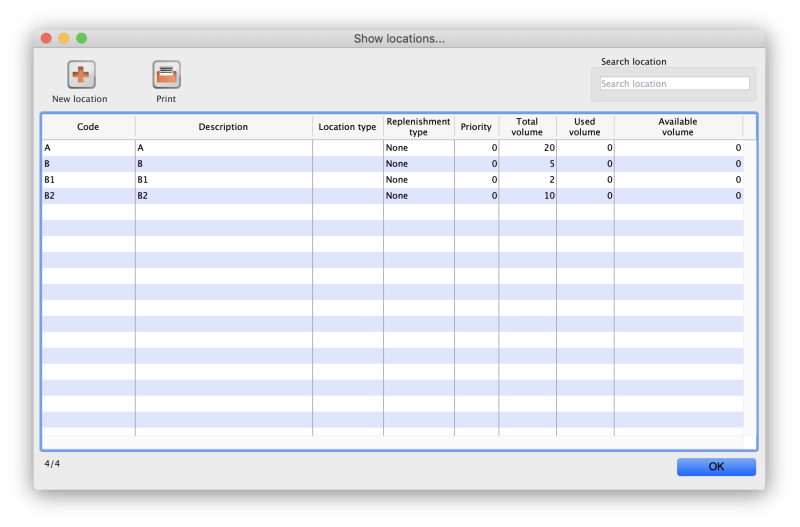

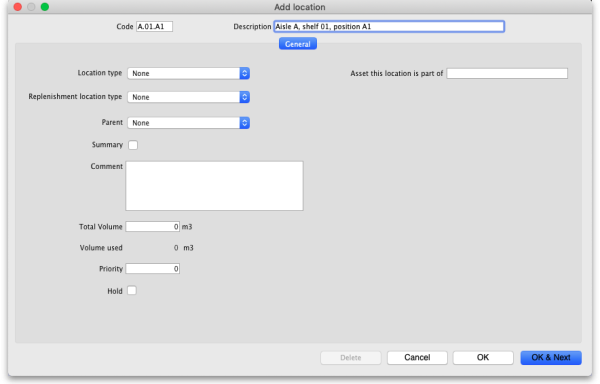

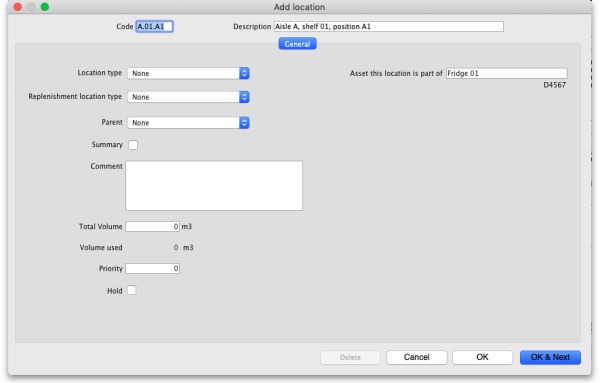

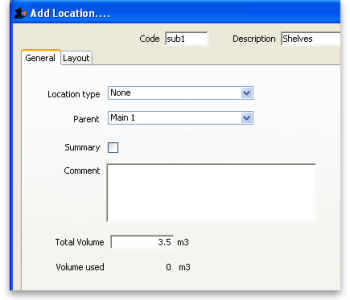

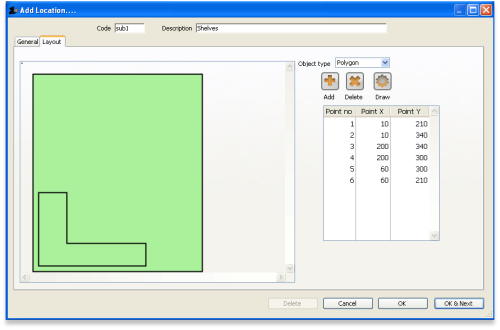

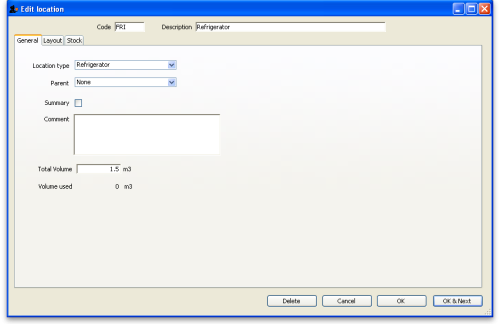

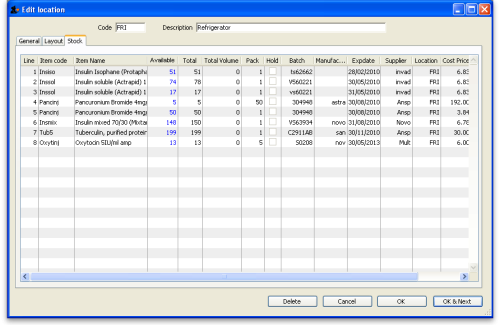

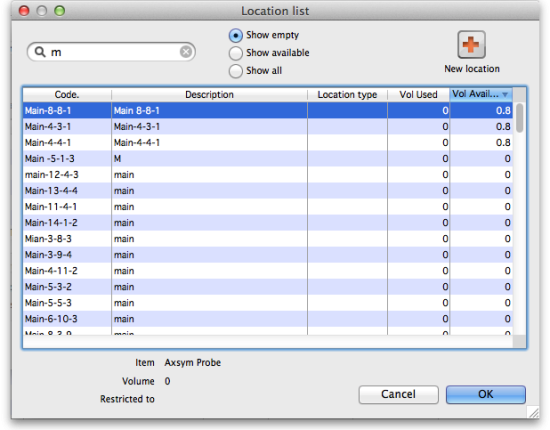

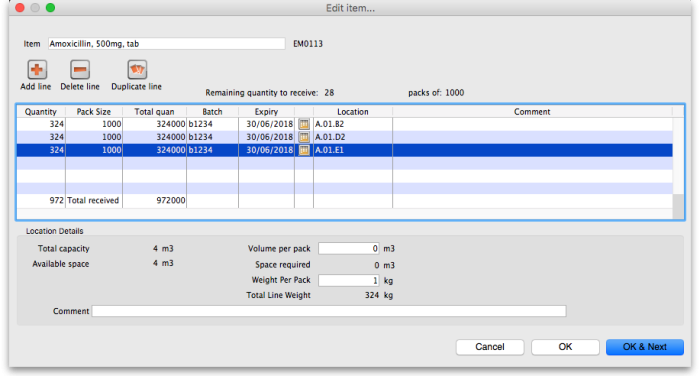

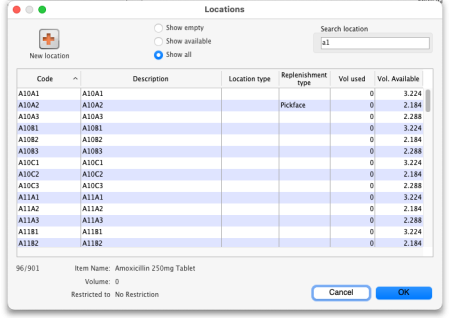

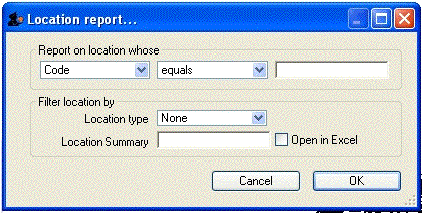

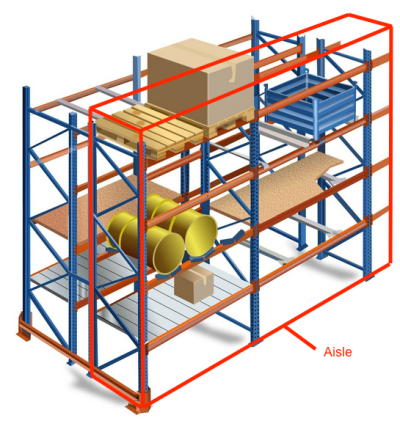

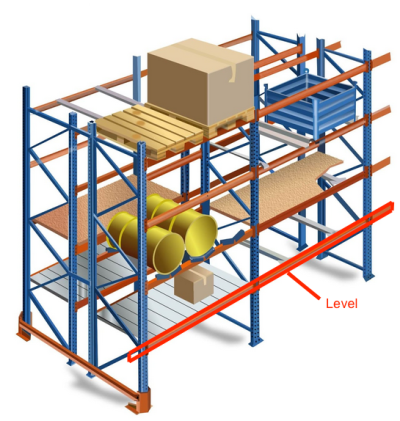

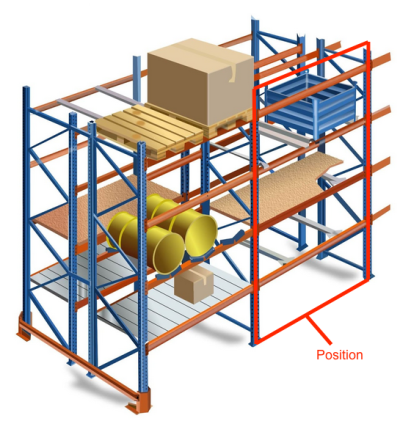

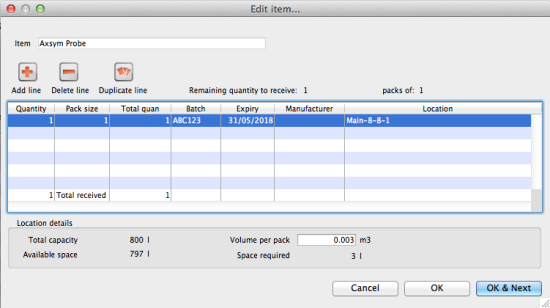

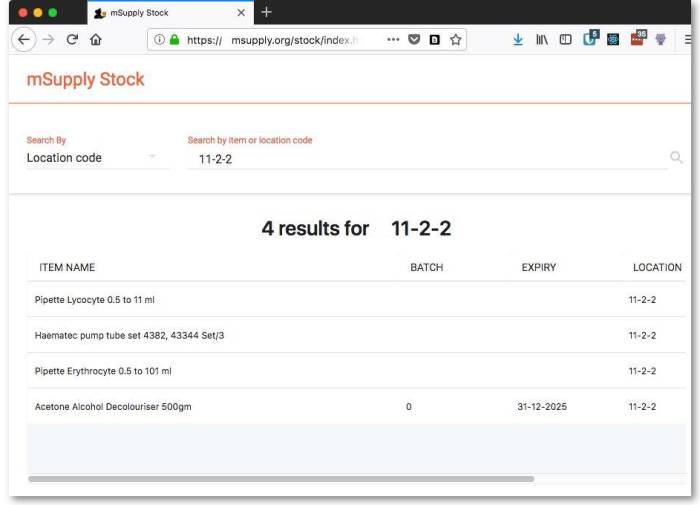

Locations: Locations are places within stores where items are kept. Locations can only exist within a store. A large store like a central warehouse may have several thousand highly specific locations (e.g. A.02.04, B.01.03), while a small store may only have a few locations (e.g. Room 1, Room 2). Items may also be stored without assigning a location: this is common in very small facilities, where items are just stored alphabetically.

People

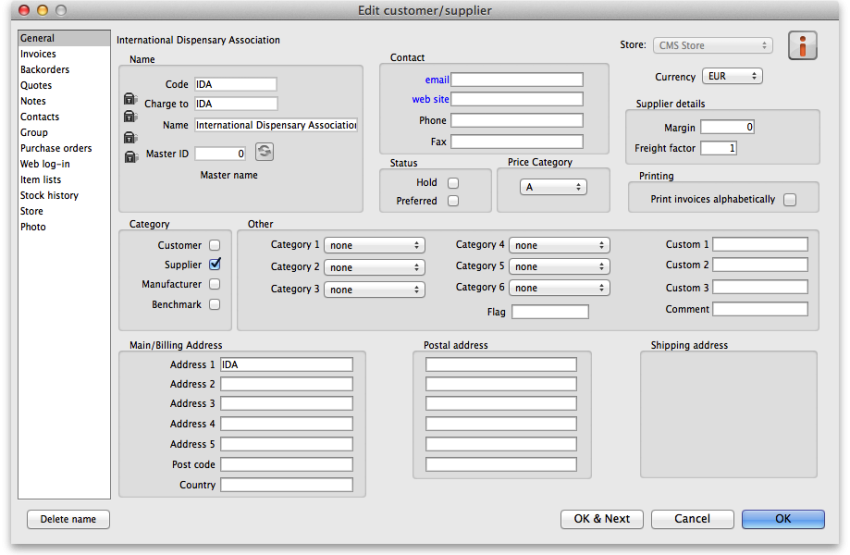

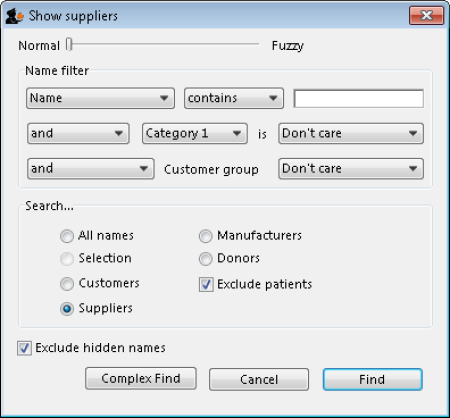

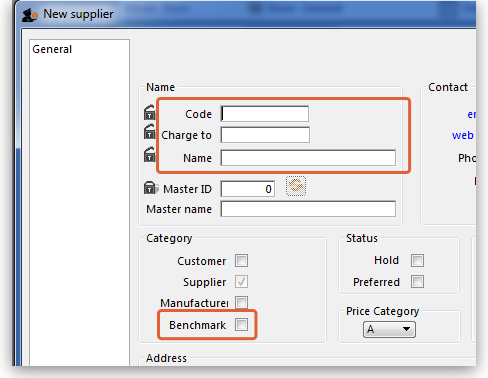

Suppliers: Suppliers are facilities that a store orders or receives stock from. Suppliers may be external (e.g. private drug companies or wholesalers) or internal (e.g. central medical store, provincial warehouses).

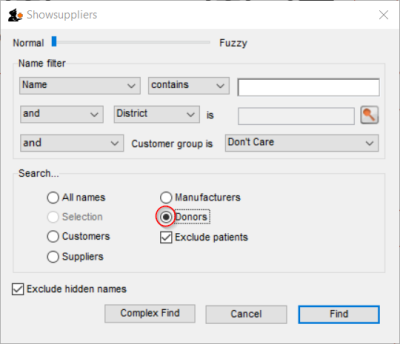

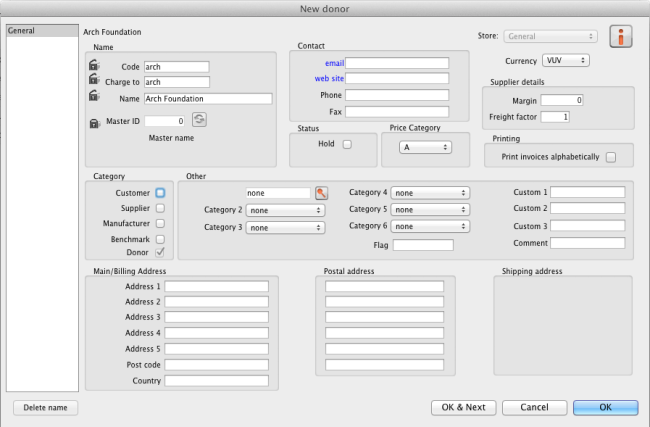

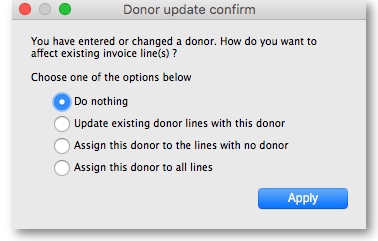

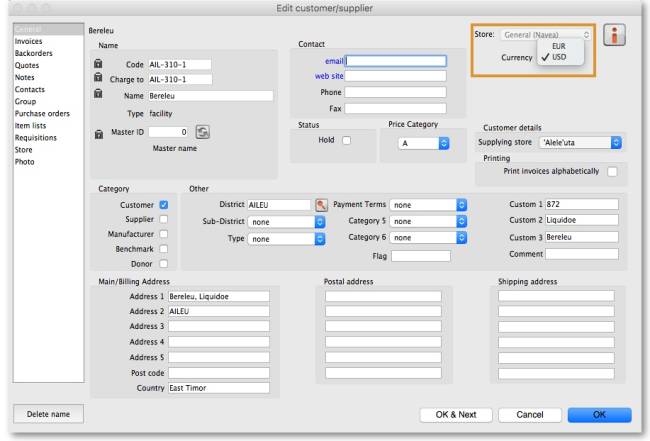

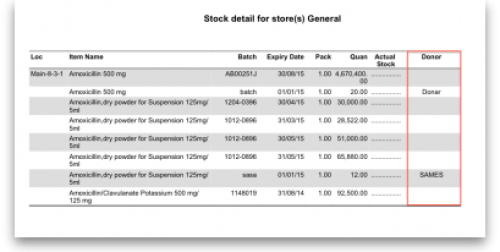

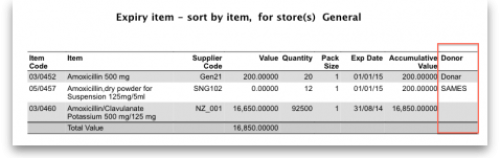

Donors: Donors are external entities who pay for donated stock (e.g. UNICEF, USAID). No donor is entered when the government or medical store is paying in a normal financial transaction. When the donor is recorded, you can track donated items through the supply chain and run donor transaction reports and stocktakes.

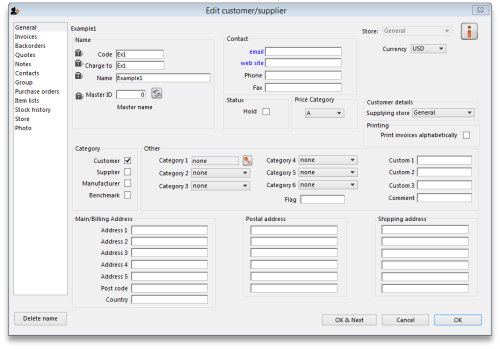

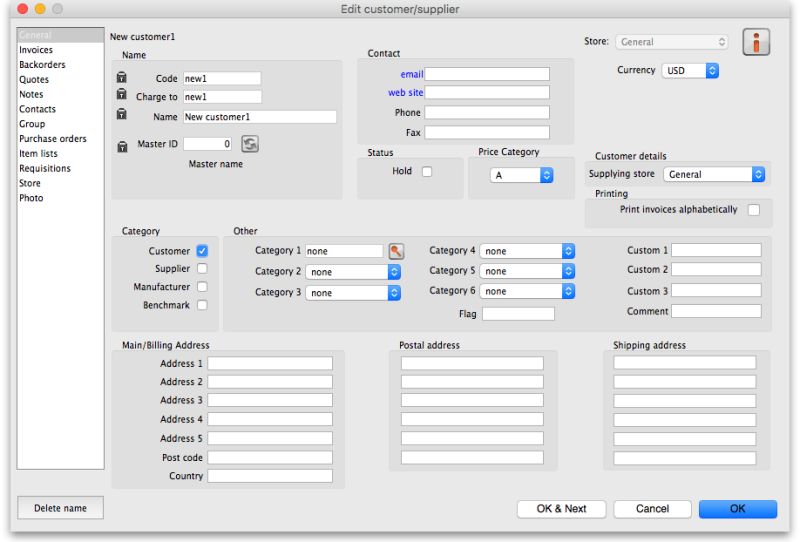

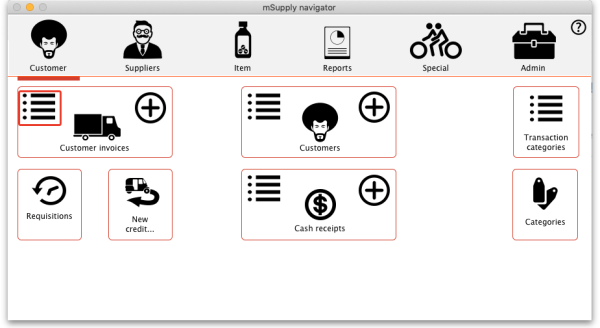

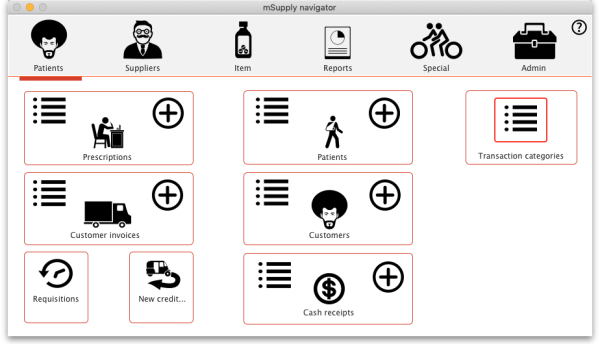

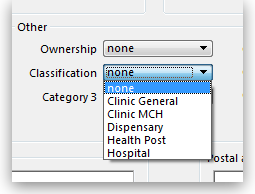

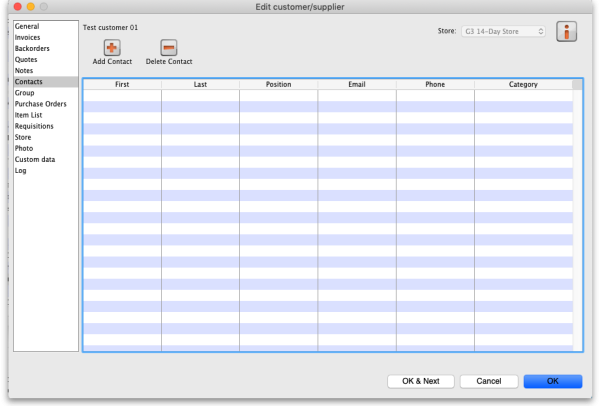

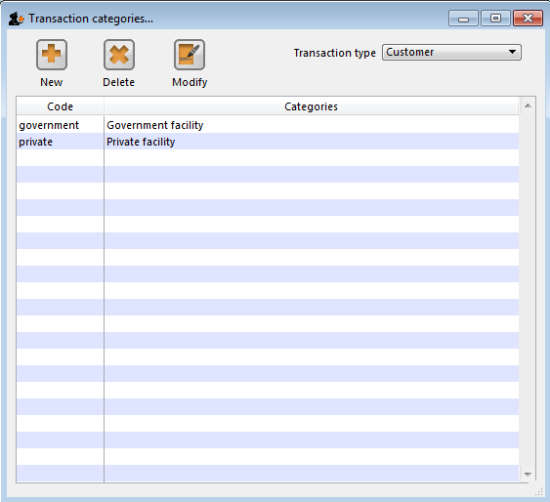

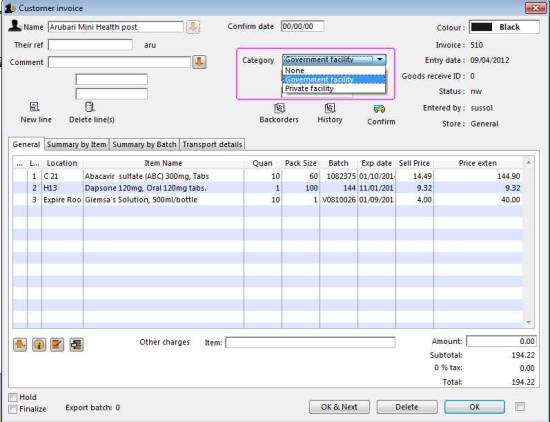

Customers: Customers are recipients of items, excluding patients (usually). This includes health centres, hospitals, wards, private clinics and pharmacies, touring medical teams, outreach services and any other entity that an mSupply store issues stock to.

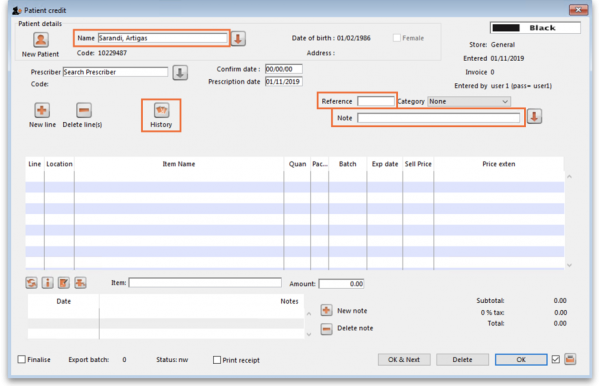

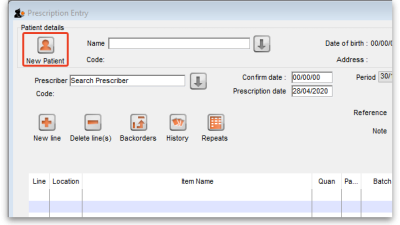

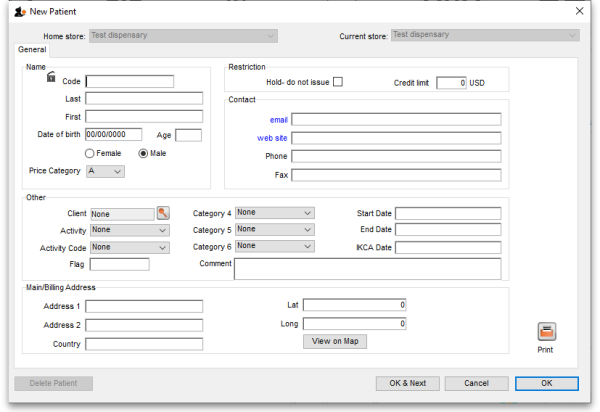

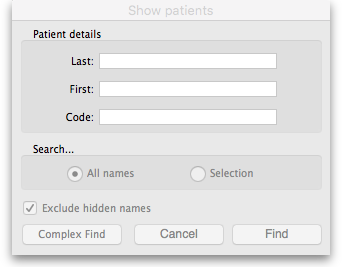

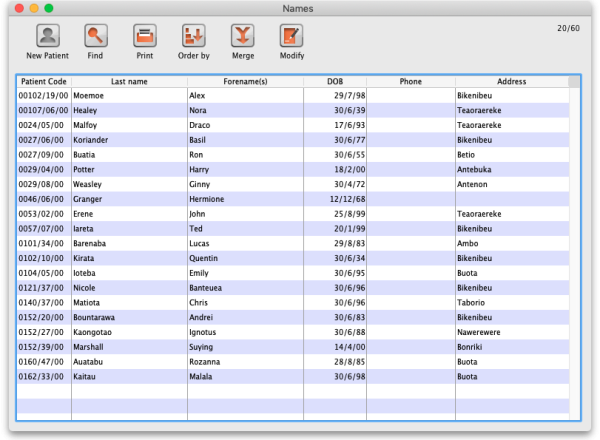

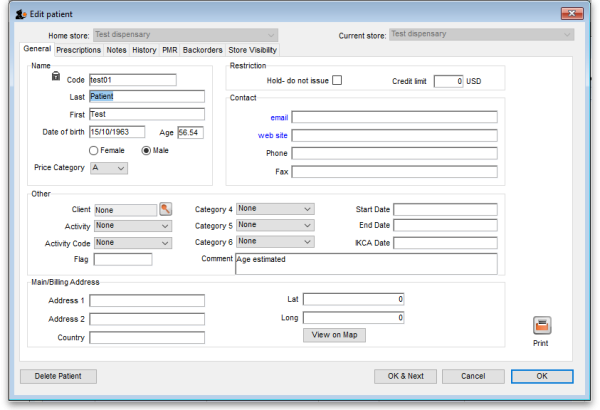

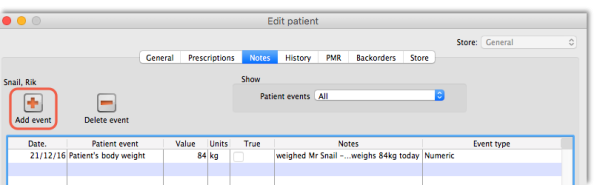

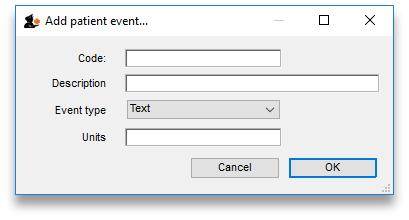

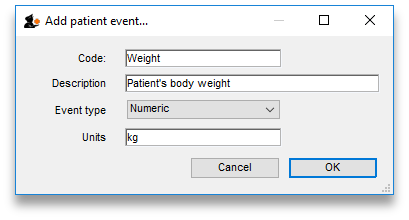

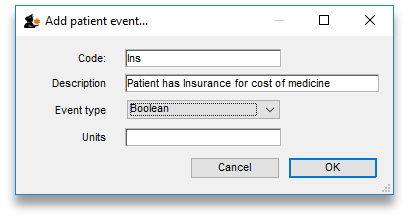

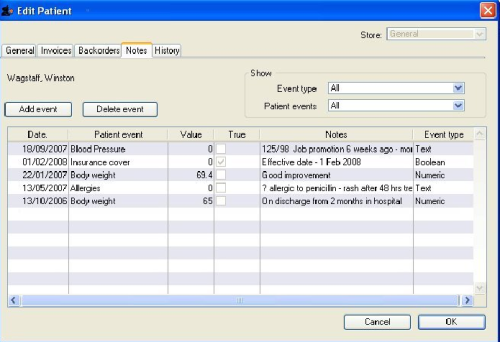

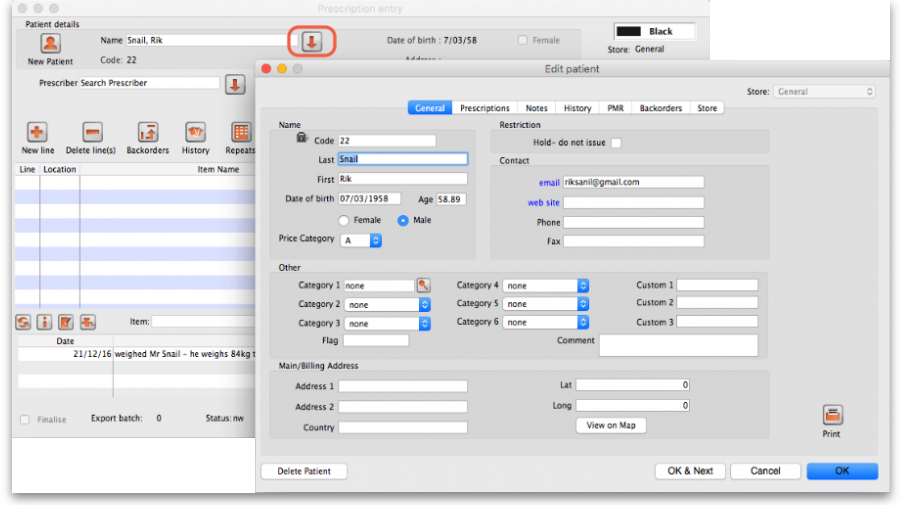

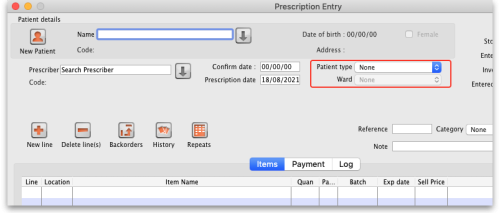

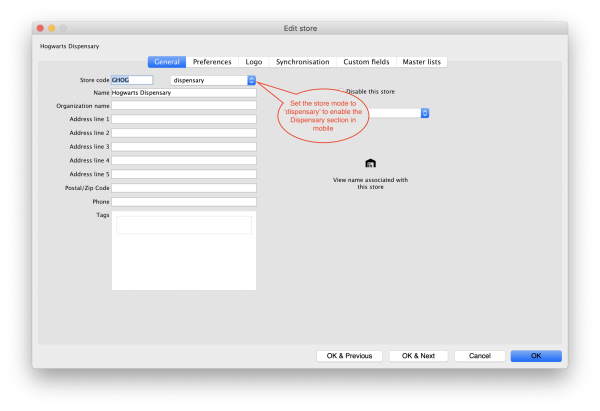

Patients: Patients are individual people who receive items from a prescription. When a store uses mSupply in dispensary mode, patients receive unique ID numbers and we can track their prescription history, allergies, payment history, insurers and notes.

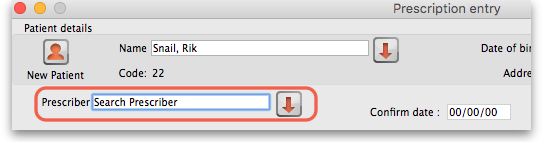

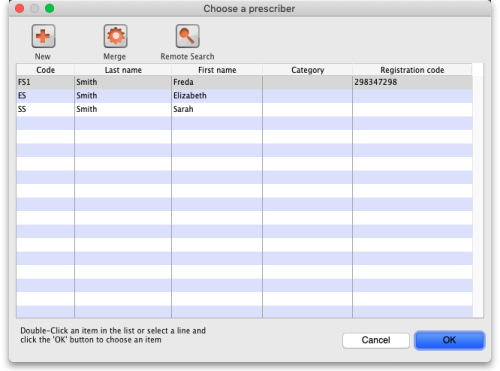

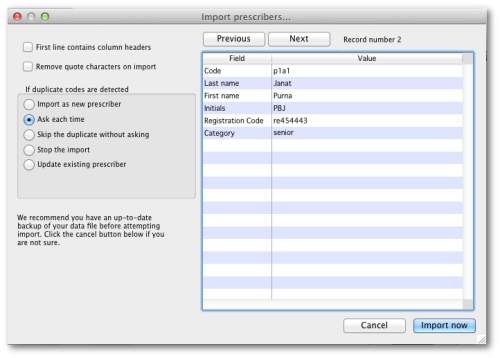

Prescribers: Prescribers are authorised medical professionals who provide prescriptions to patients, which we can dispense in mSupply. Prescribers may include doctors, nurses and other authorised individuals.

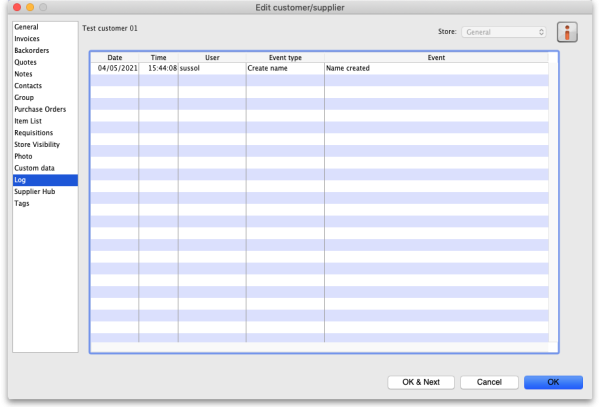

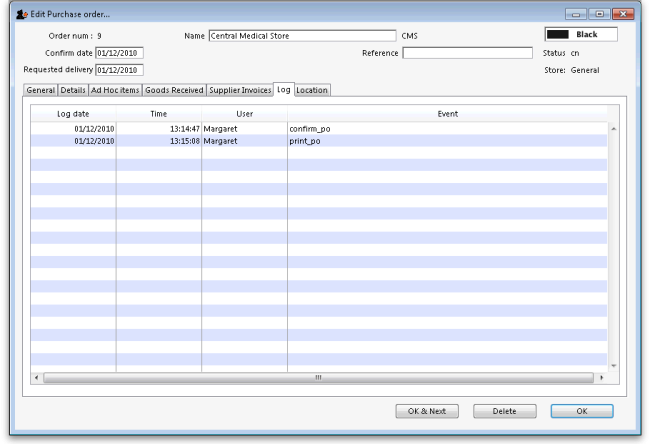

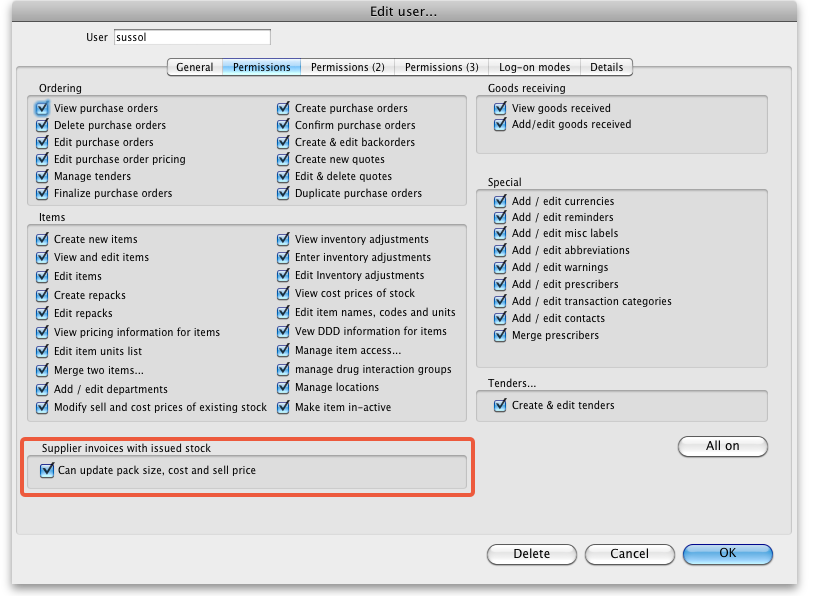

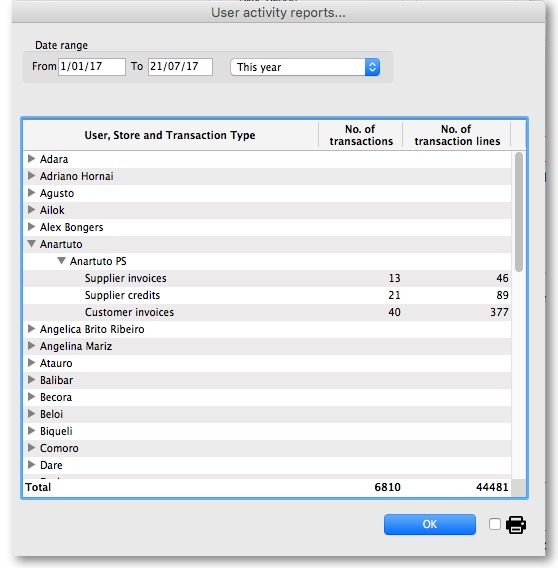

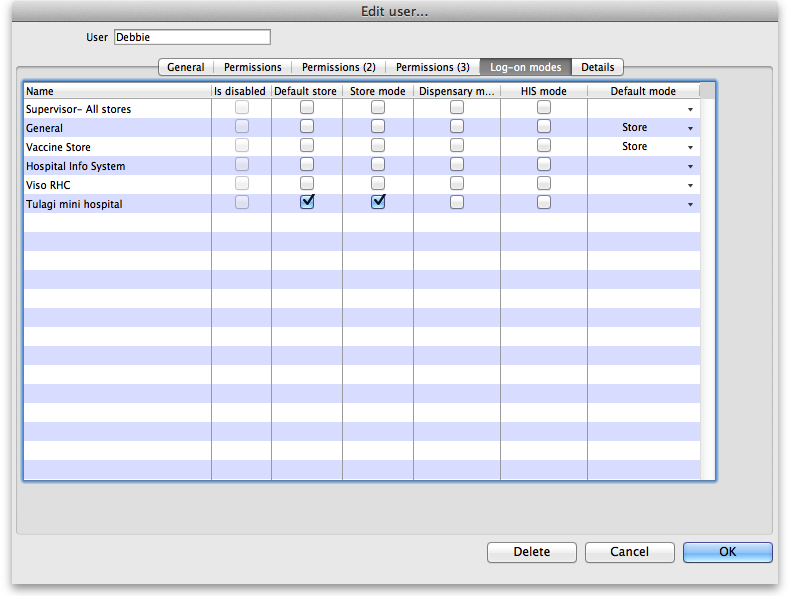

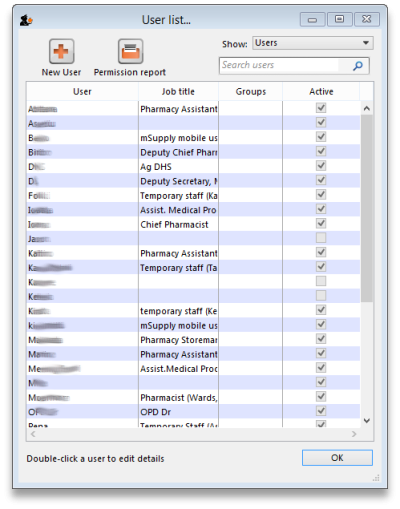

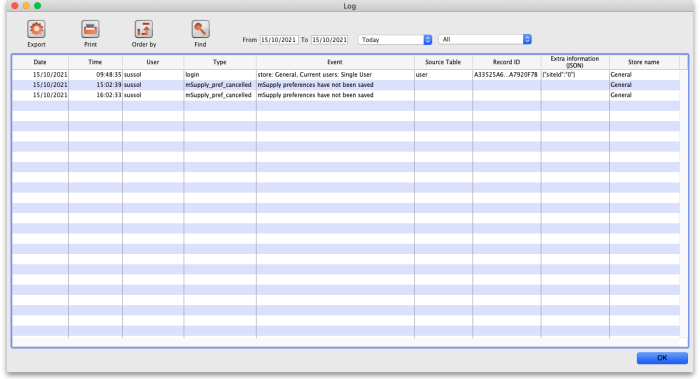

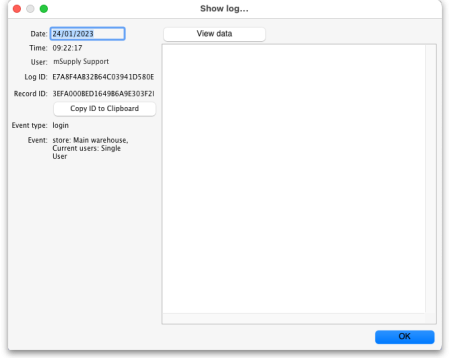

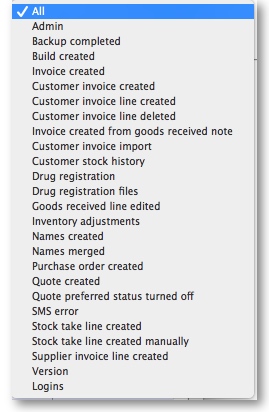

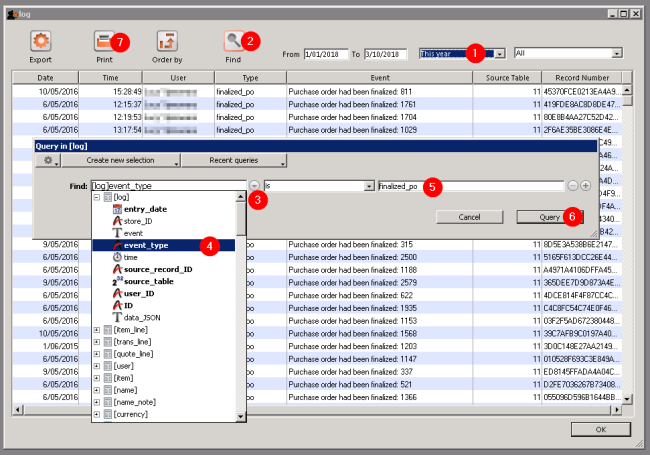

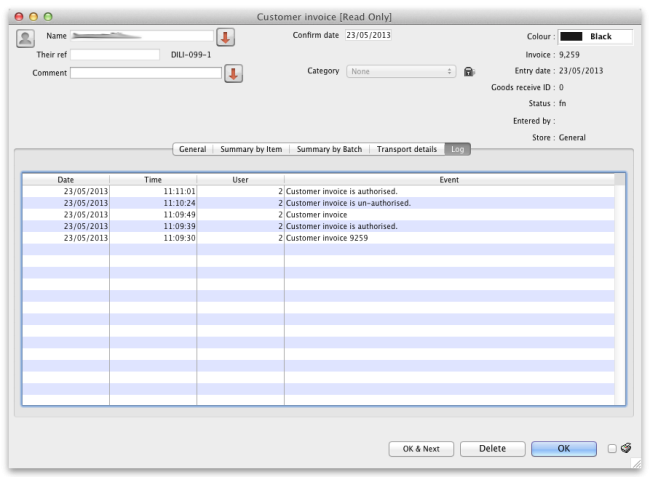

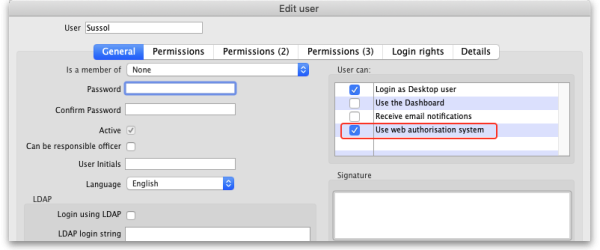

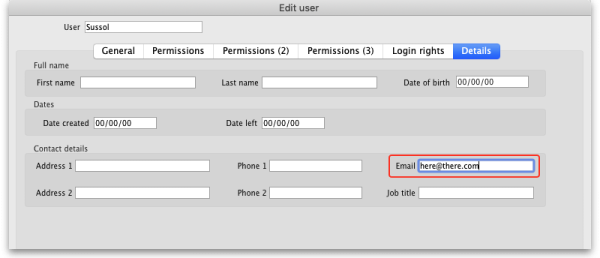

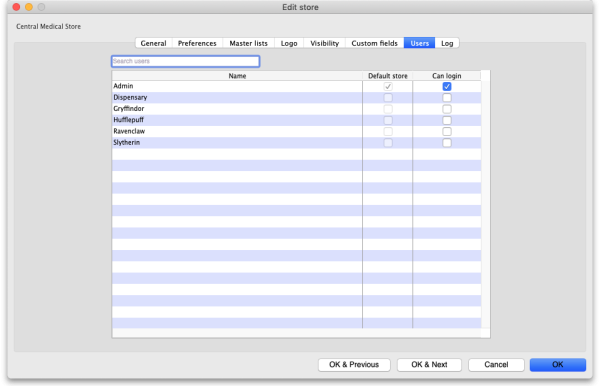

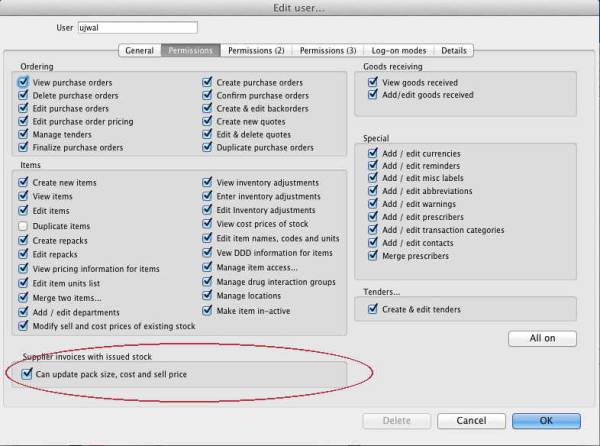

Users: Users are the people using mSupply (you!). Each user has their own password and set of permissions (which can vary from store to store). System logs track everything that users do in mSupply.

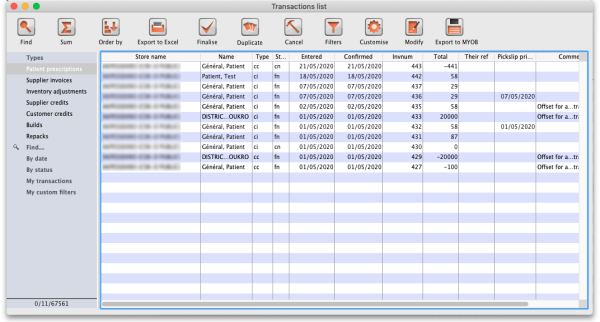

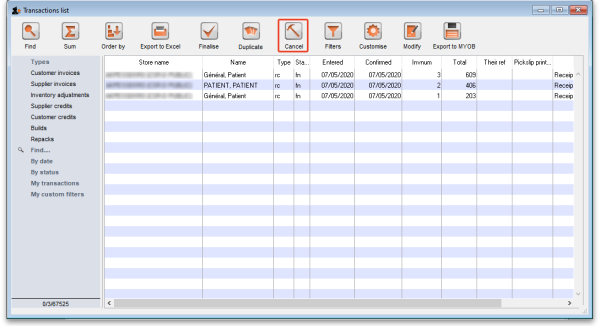

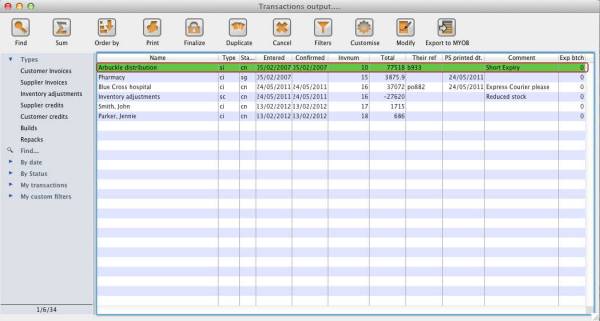

Transactions and Features

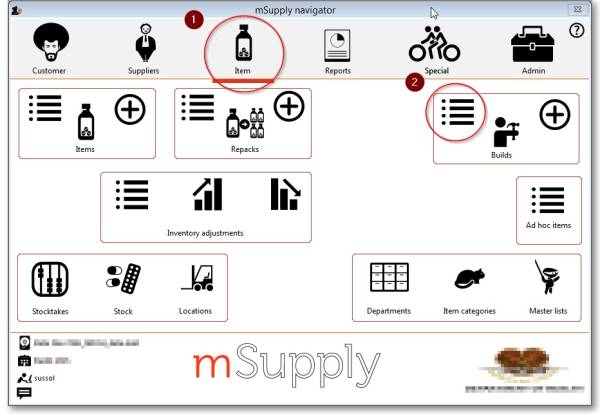

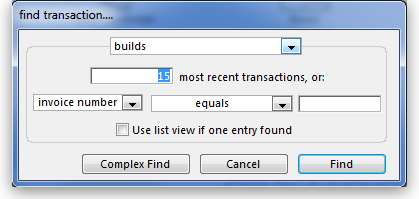

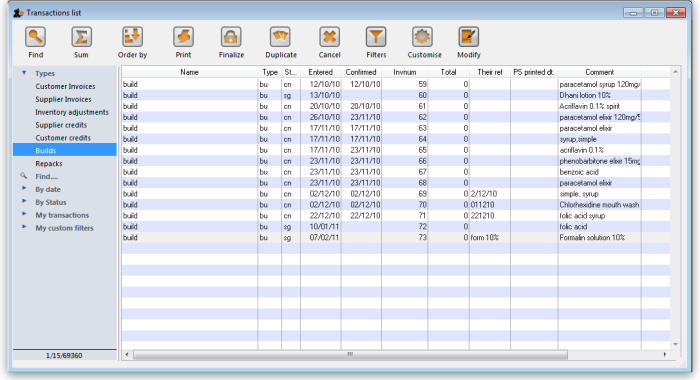

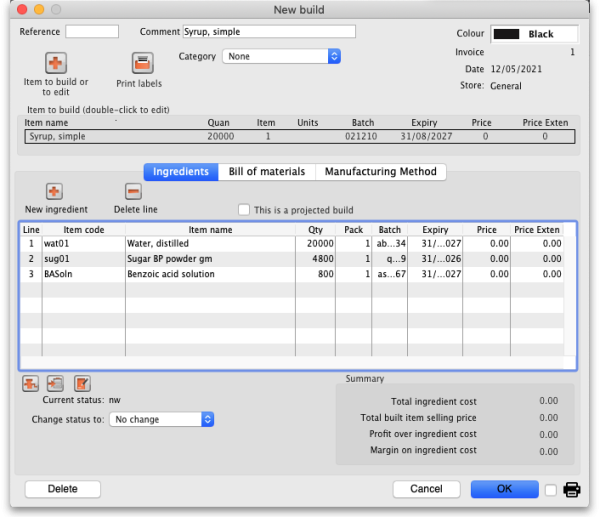

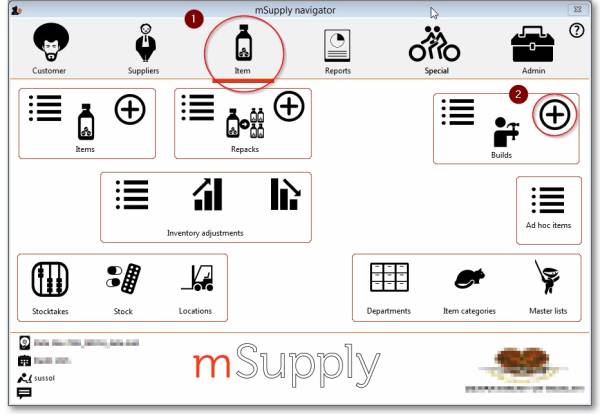

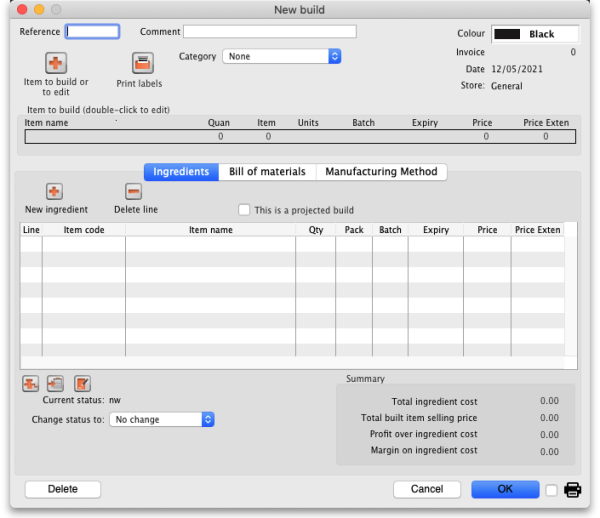

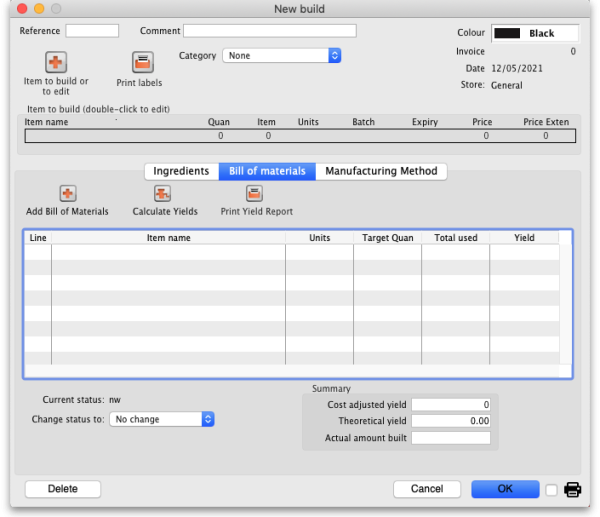

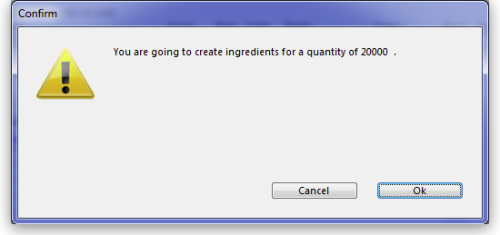

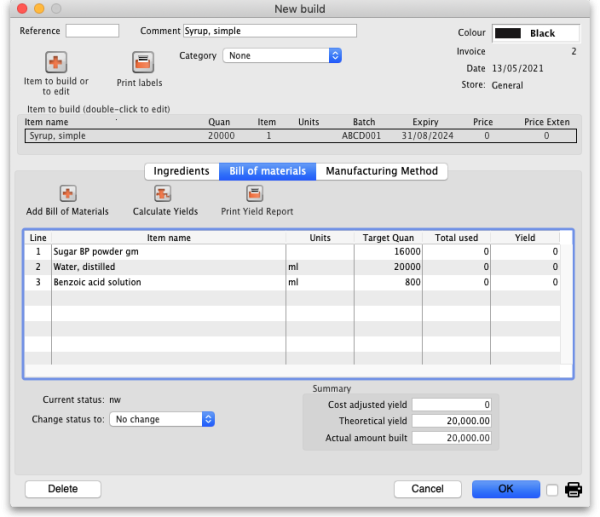

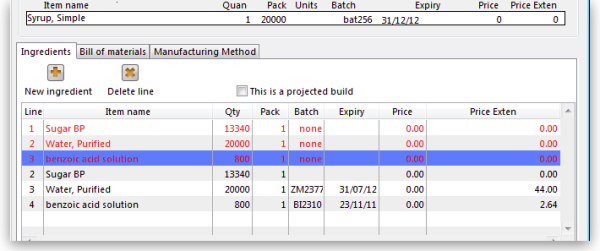

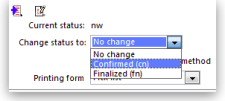

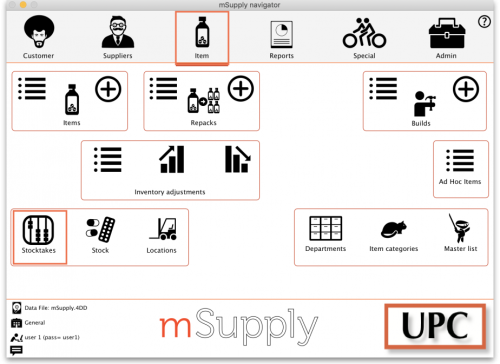

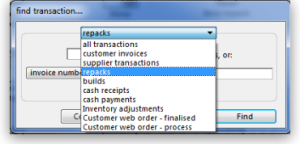

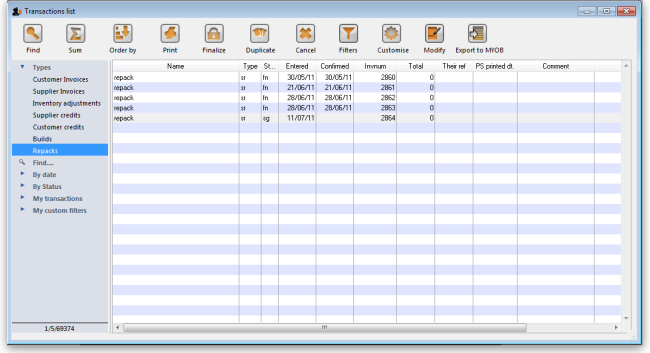

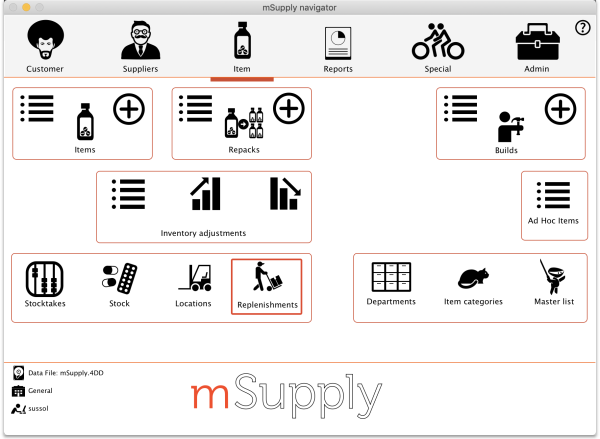

Builds: Builds are transactions that record the manufacturing of an item by turning raw materials into a finished product.

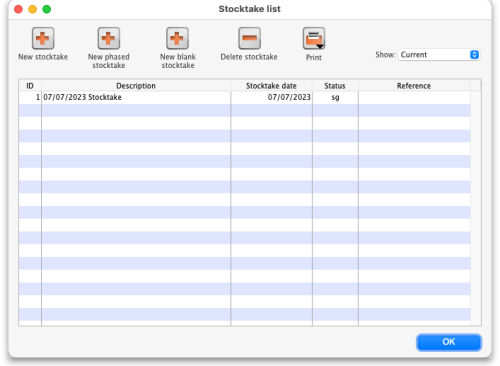

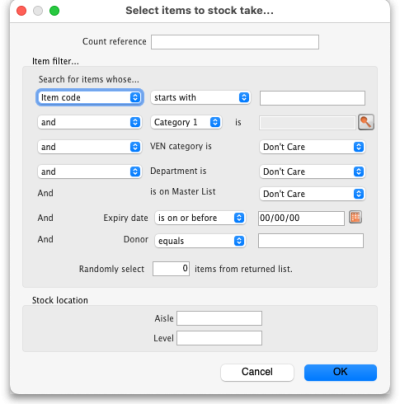

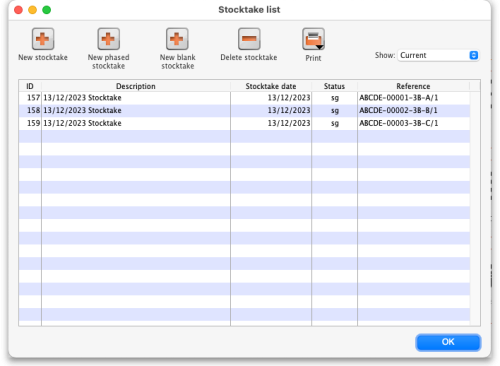

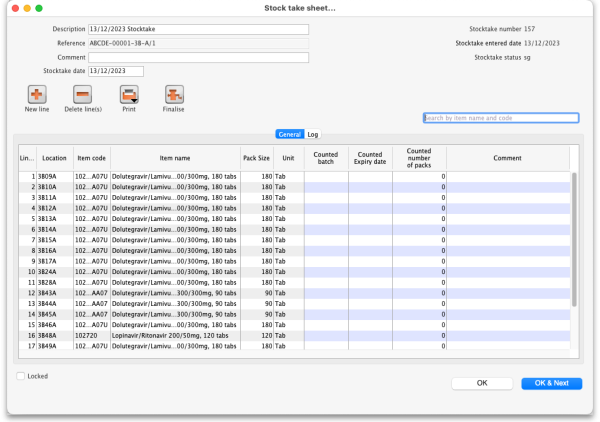

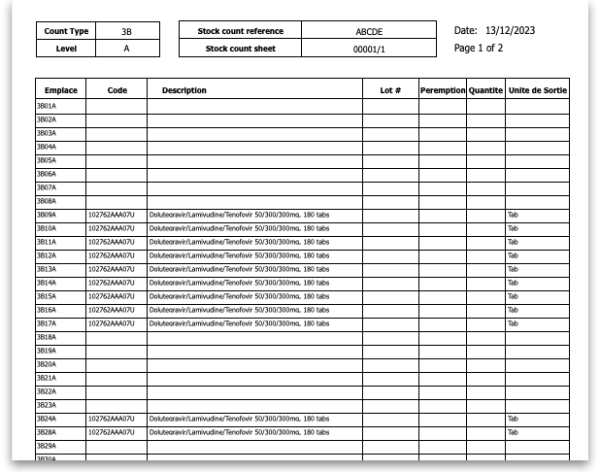

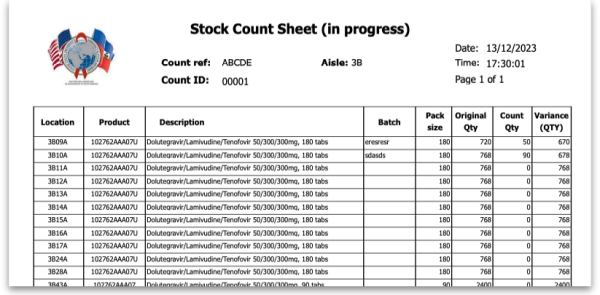

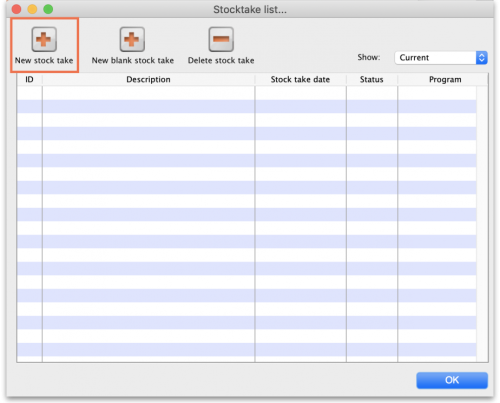

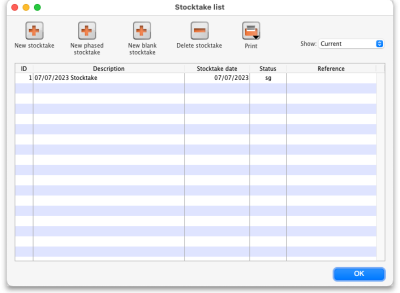

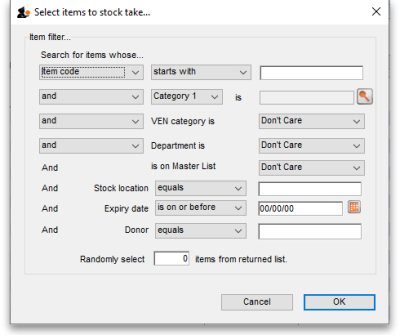

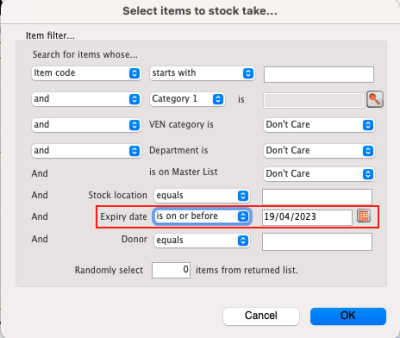

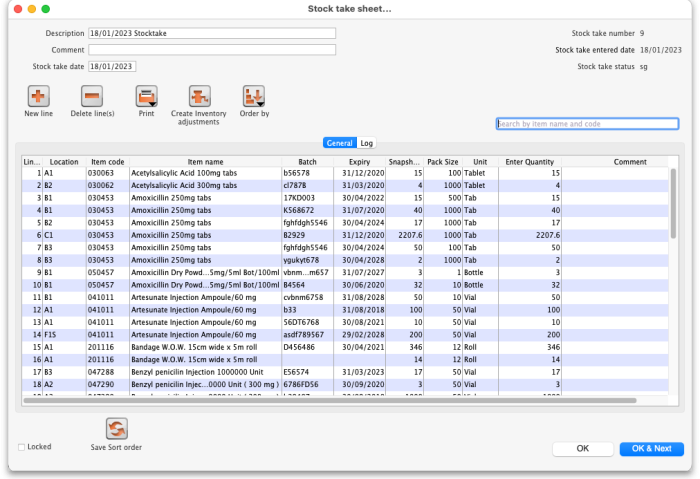

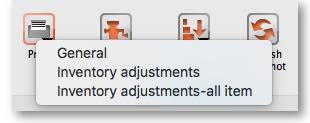

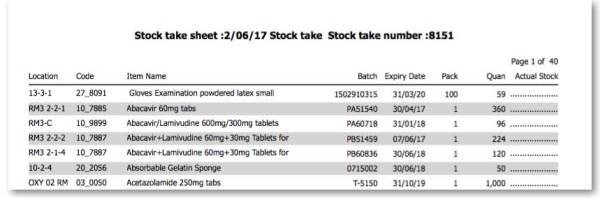

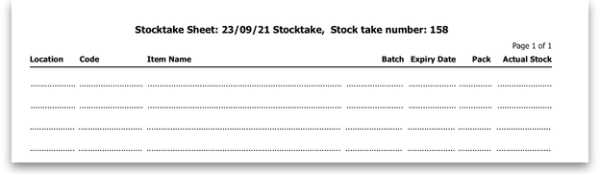

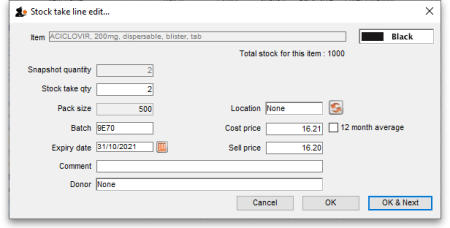

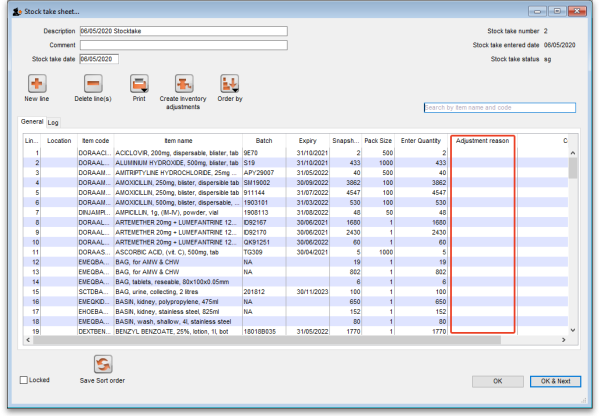

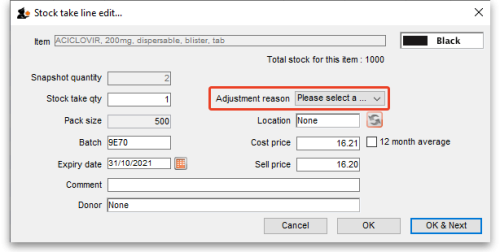

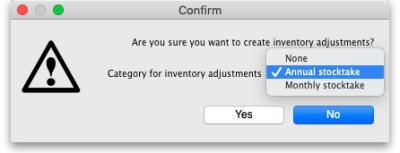

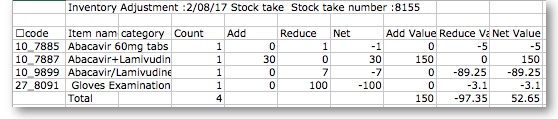

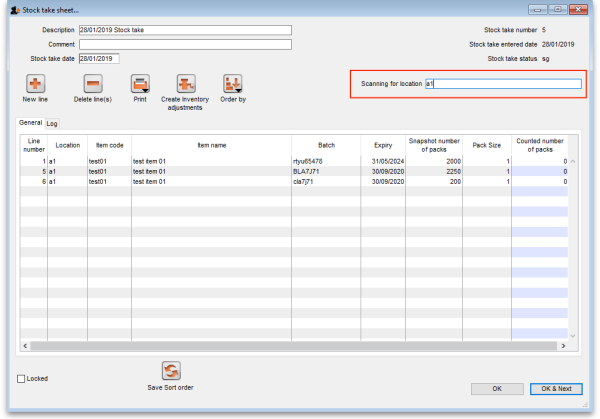

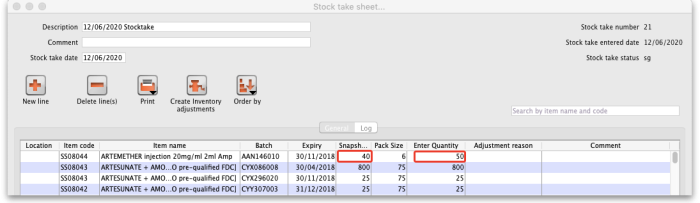

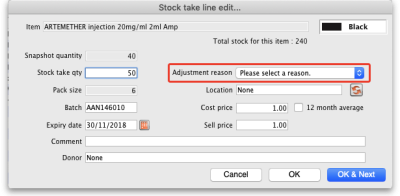

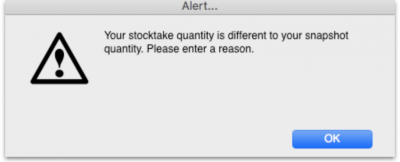

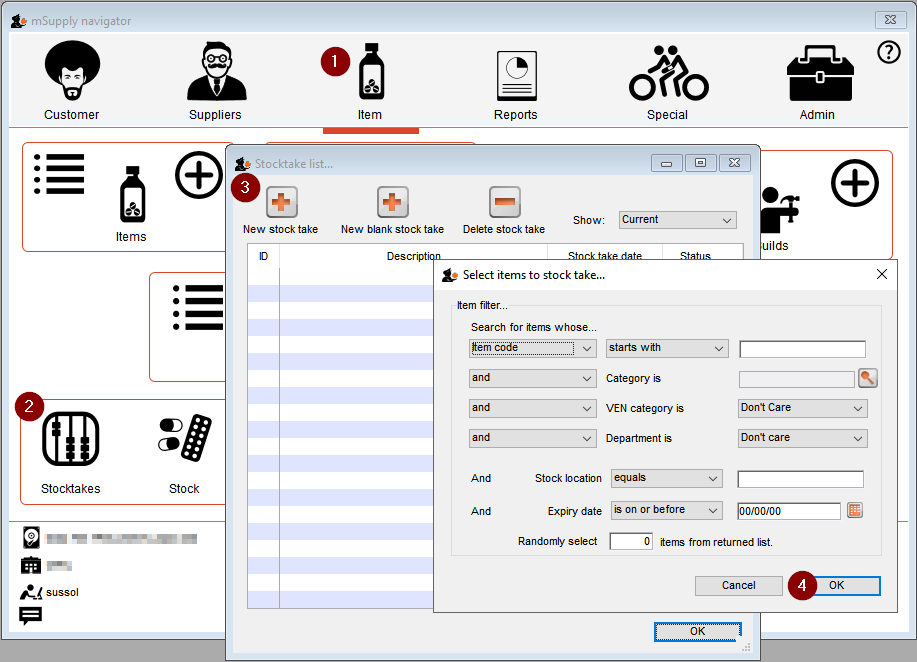

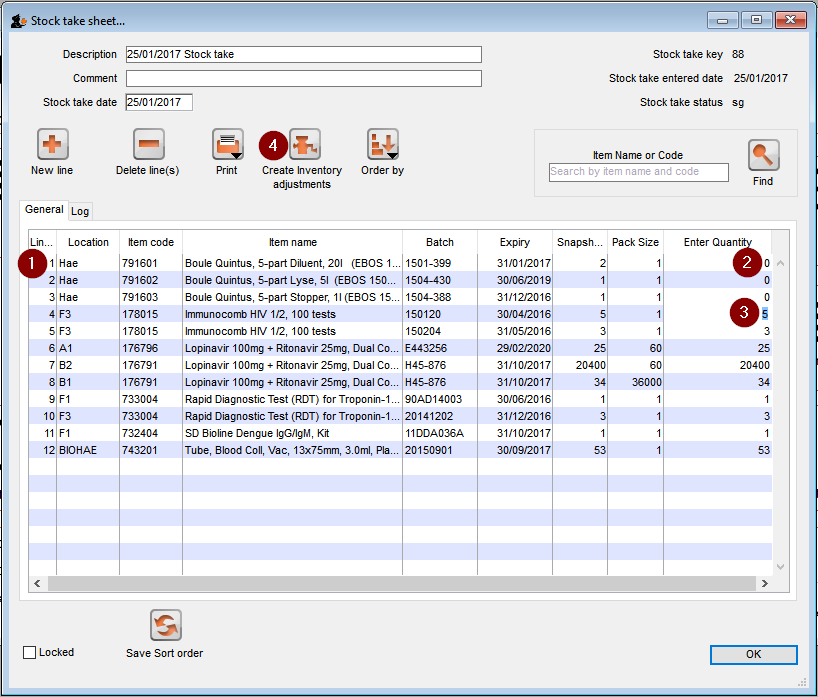

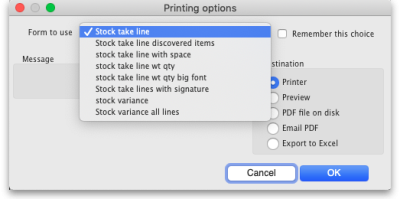

Stocktakes: Stocktakes are physical counts of the stock in your store including all item details, such as the item name, quantity, batch and expiry date.

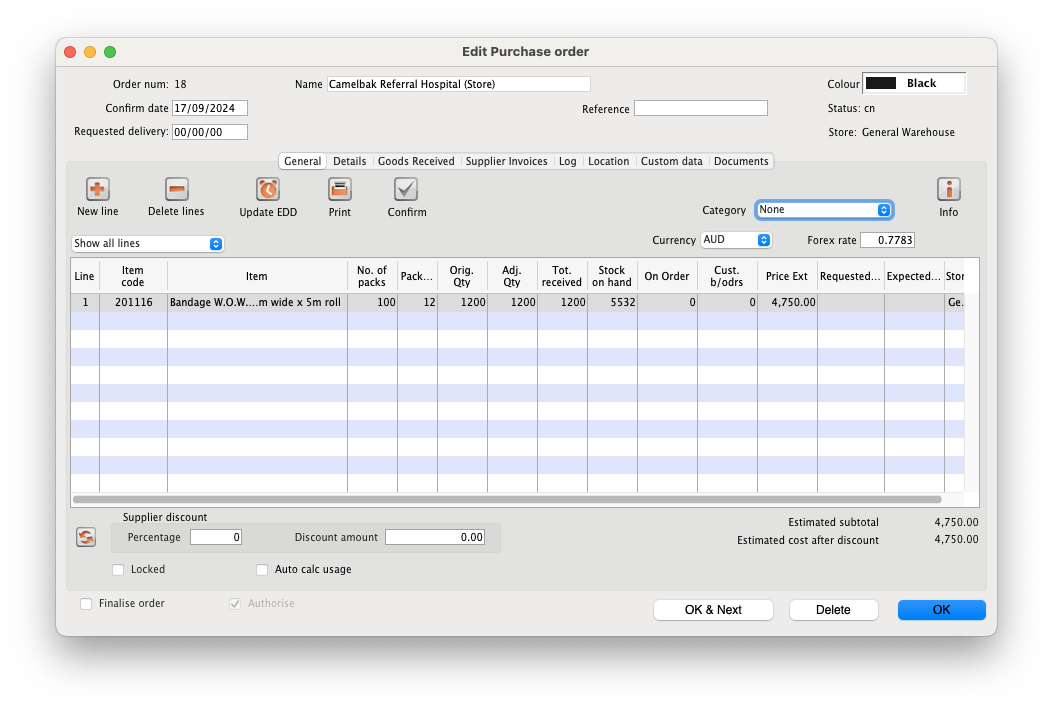

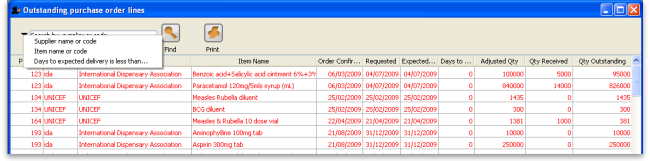

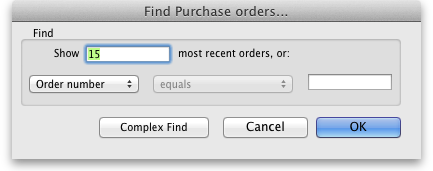

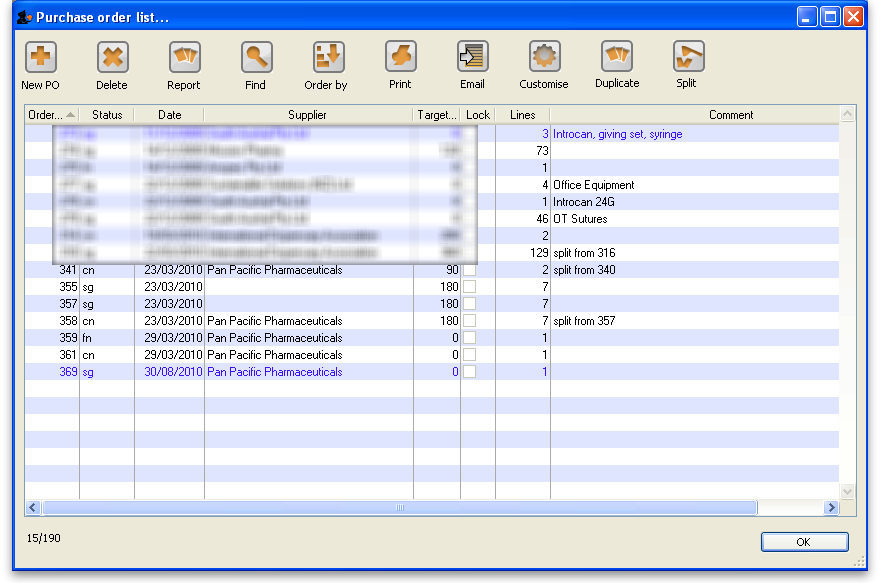

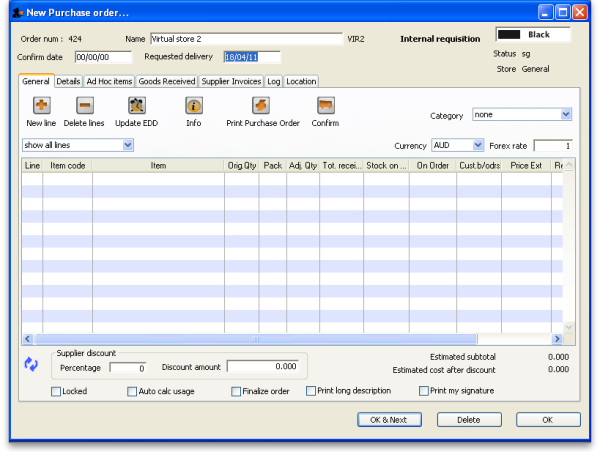

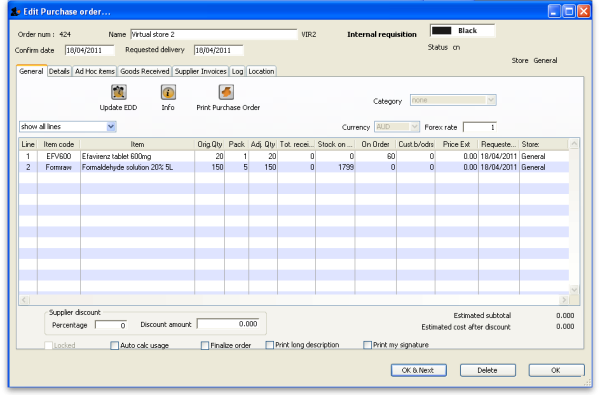

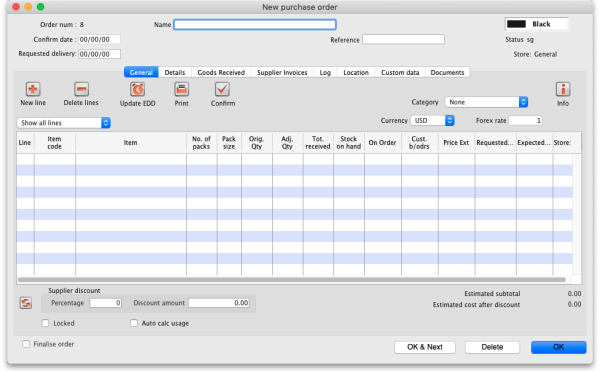

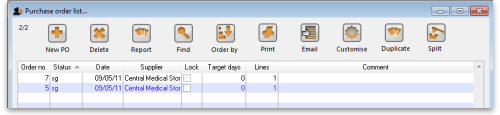

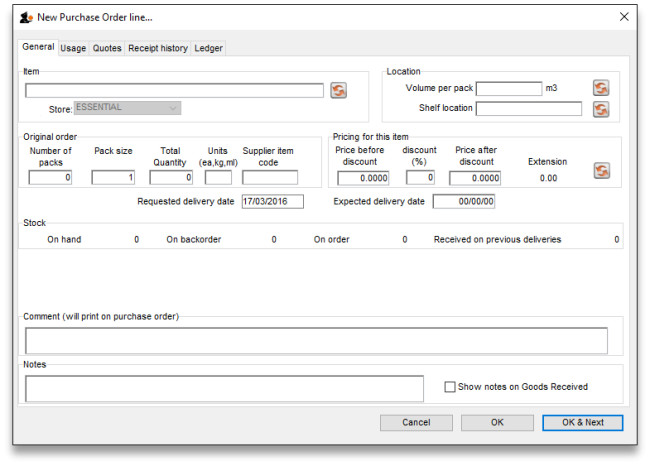

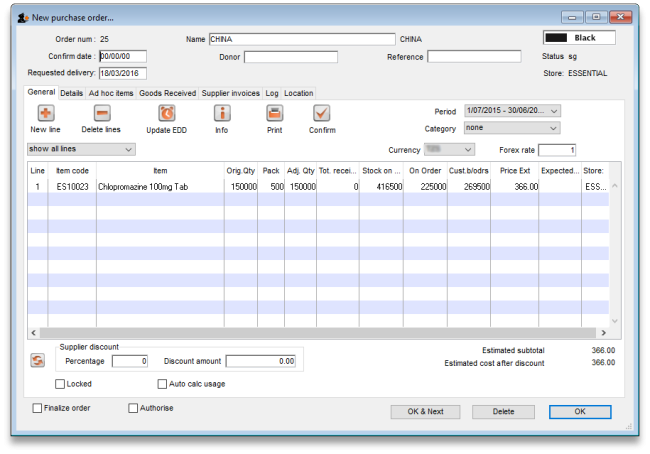

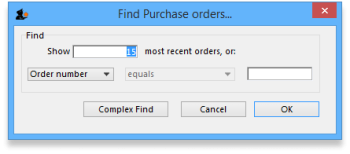

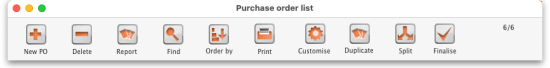

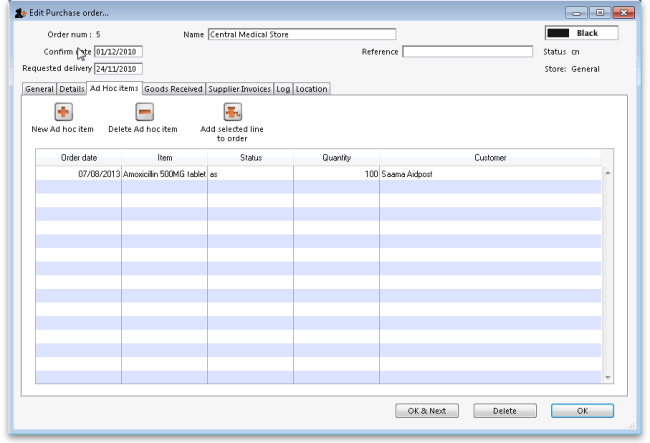

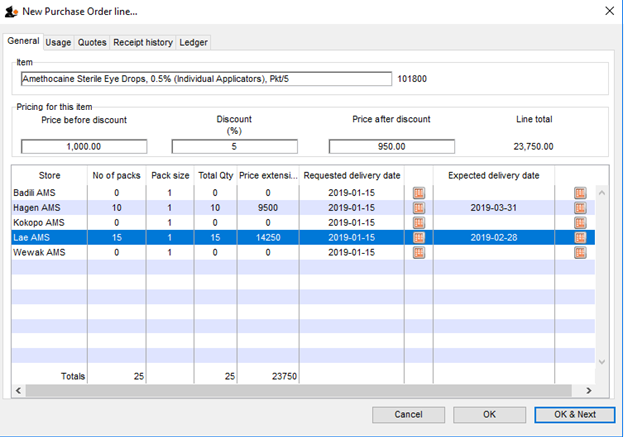

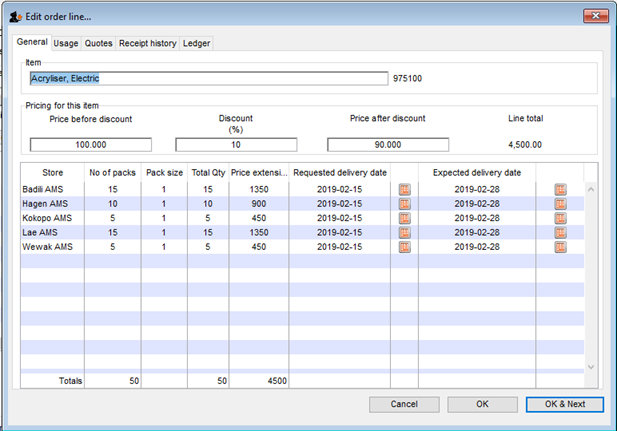

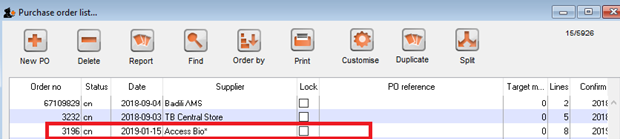

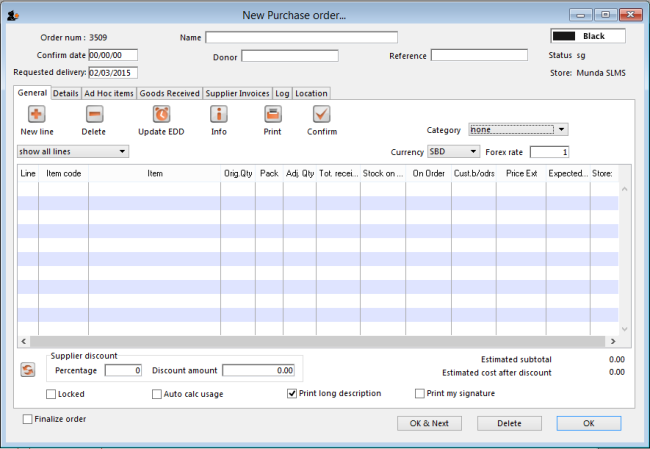

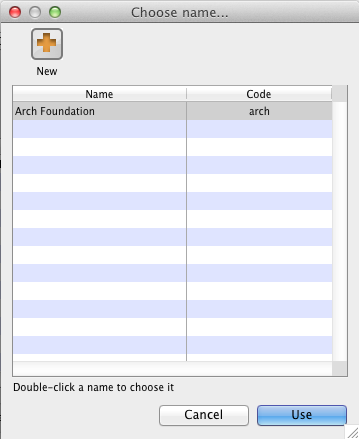

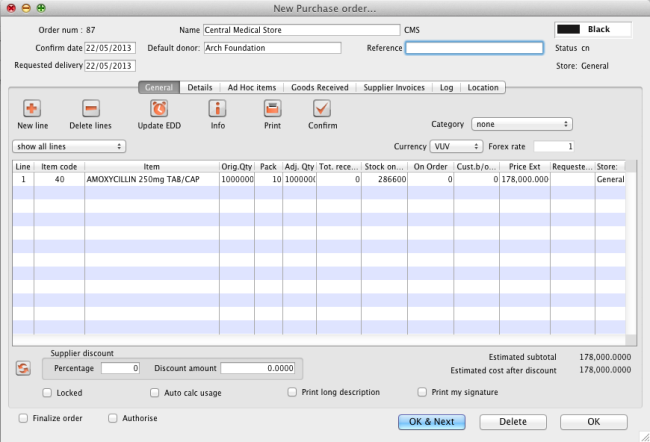

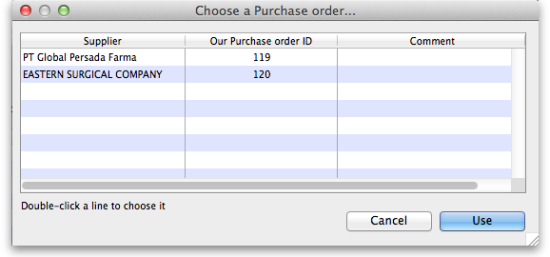

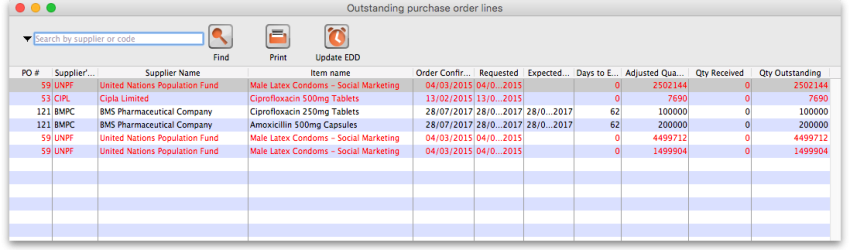

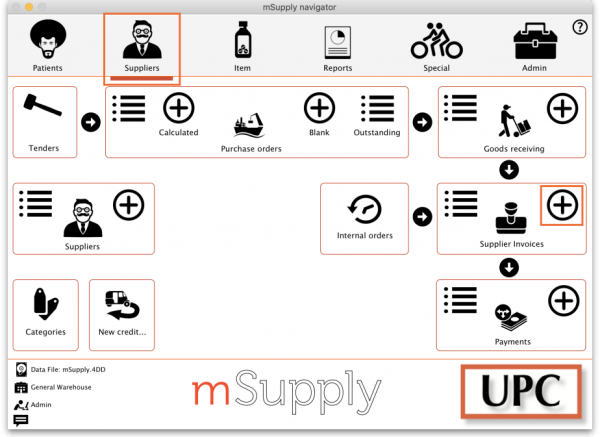

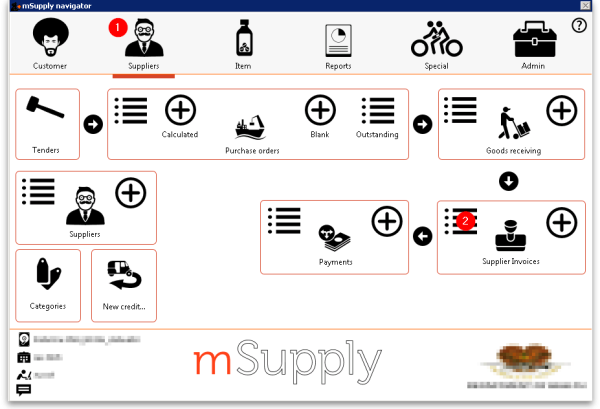

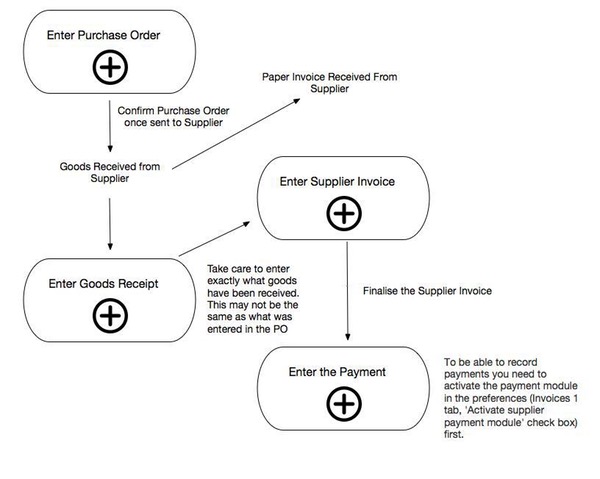

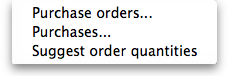

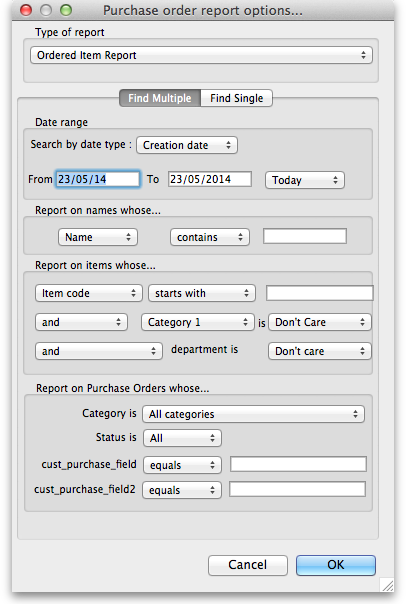

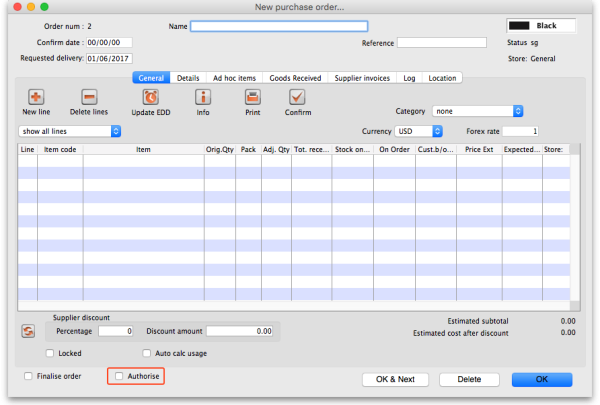

Purchase Orders: Purchase Orders are used to order stock from an external supplier i.e. a supplier who does not use mSupply (e.g. private drug companies, wholesalers, private pharmacies).

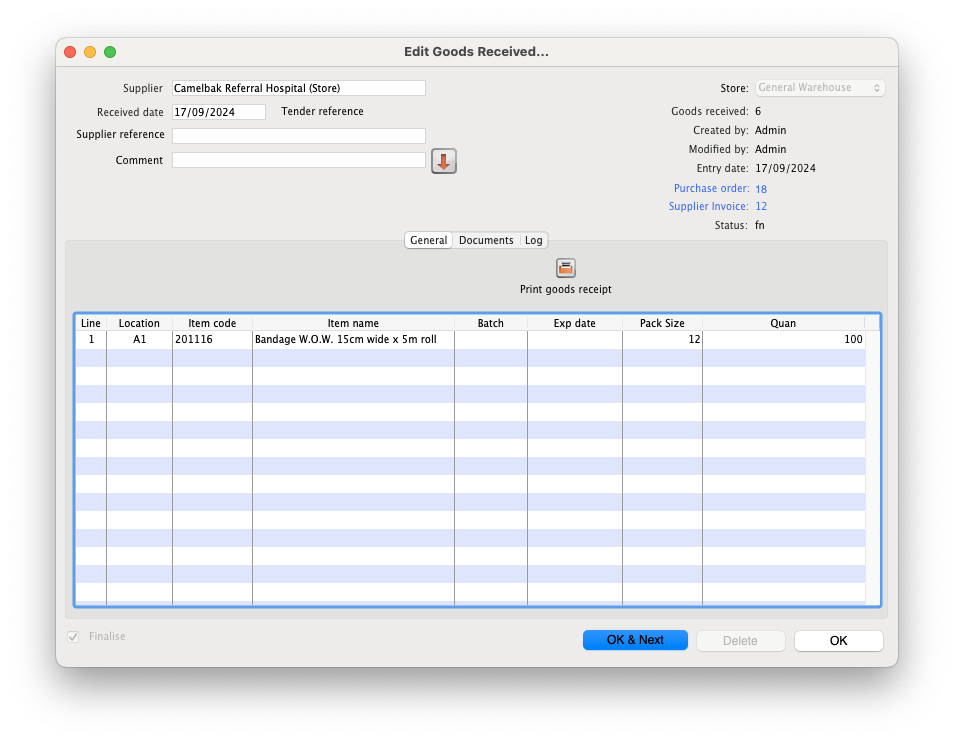

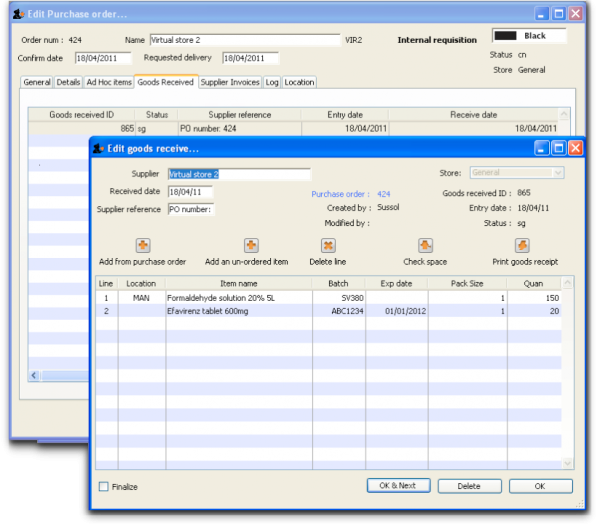

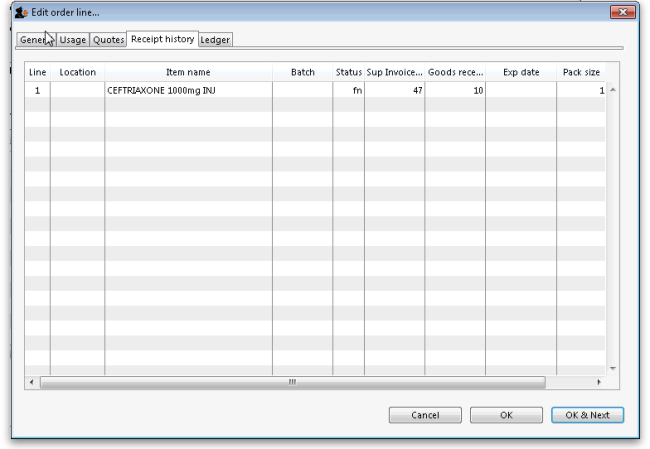

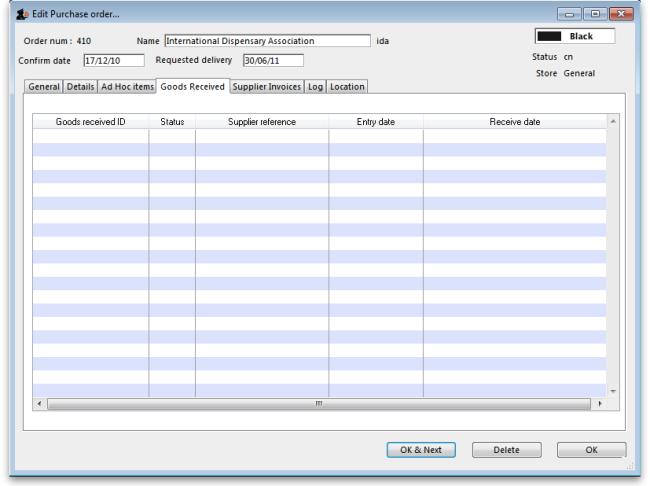

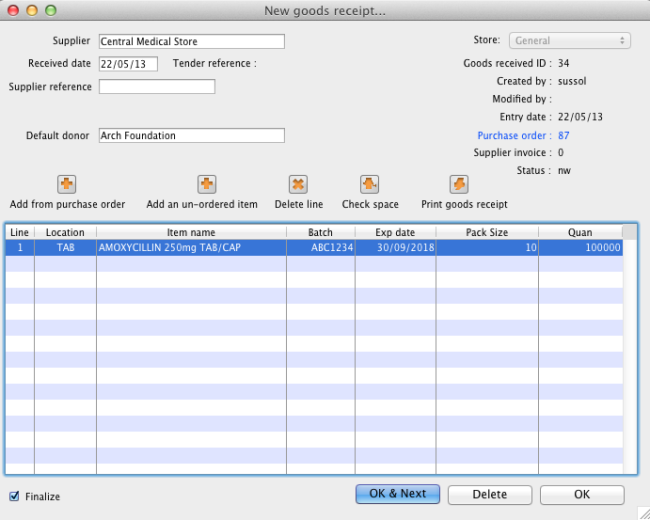

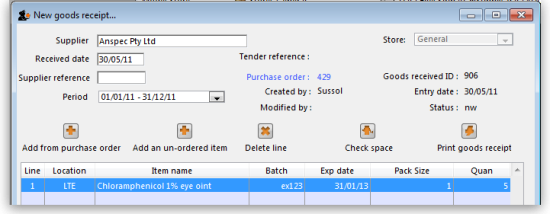

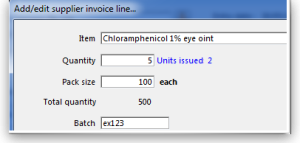

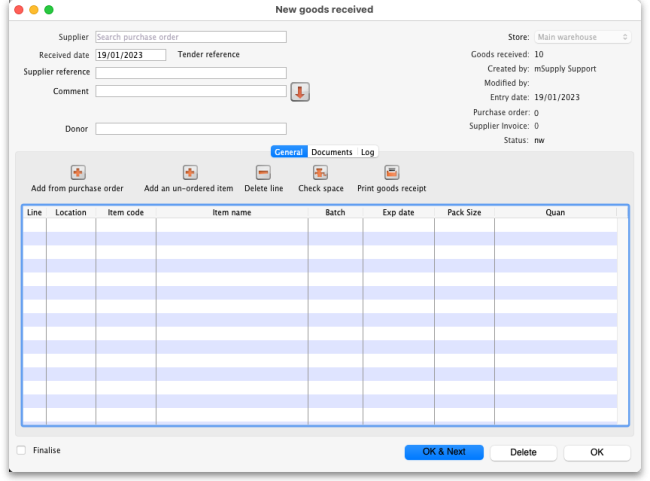

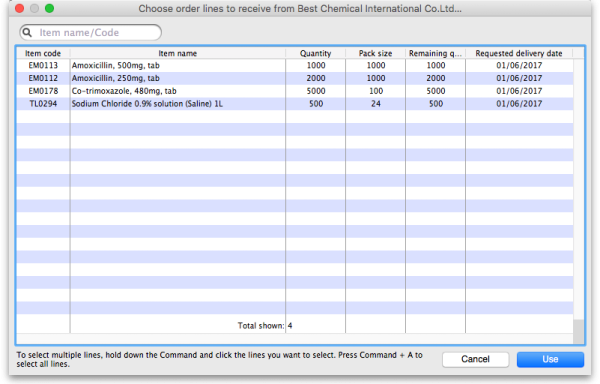

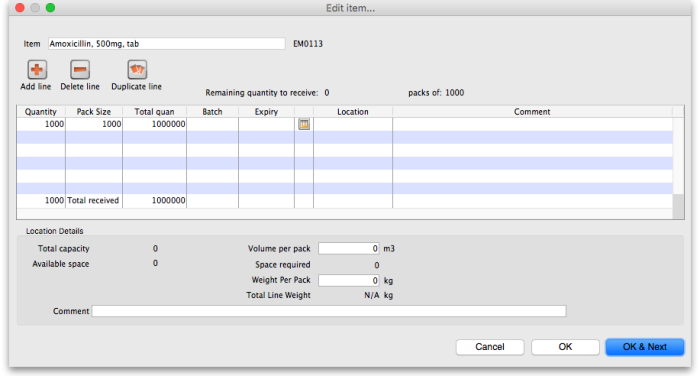

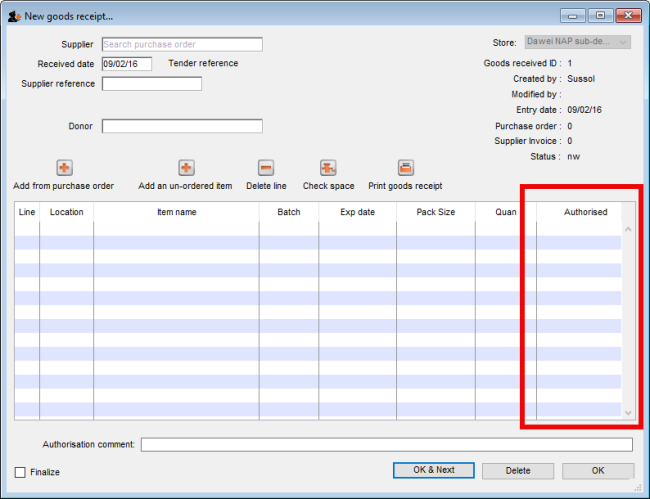

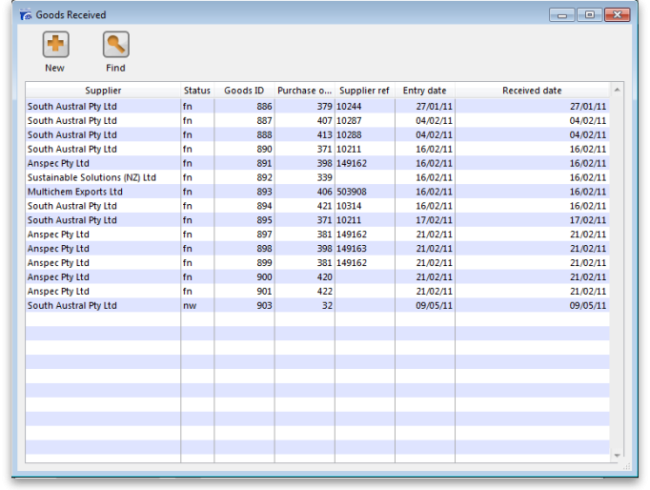

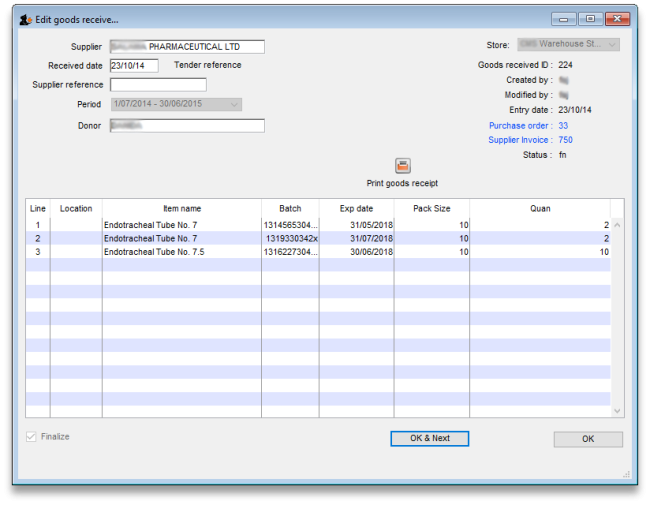

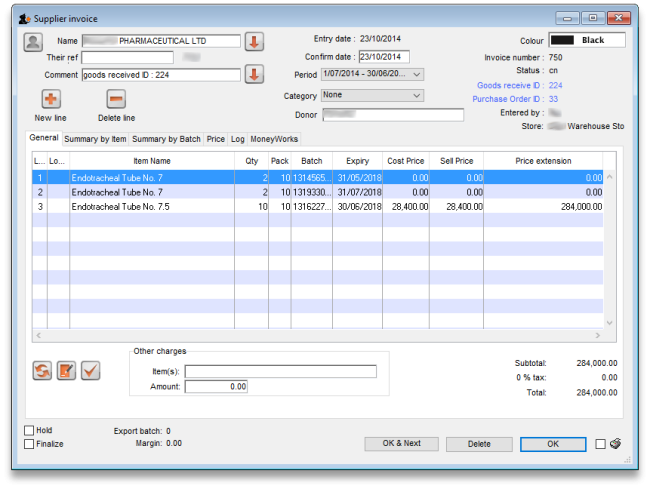

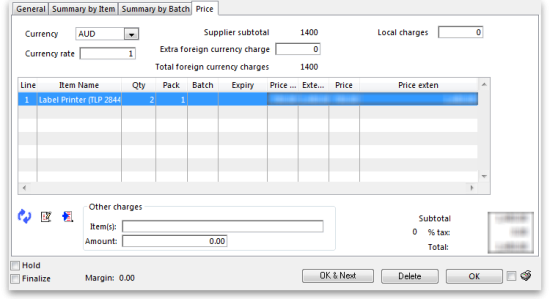

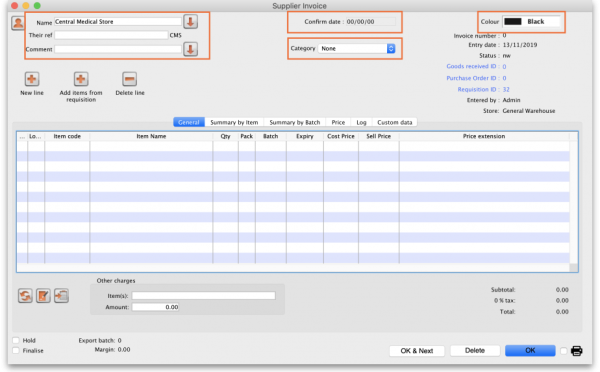

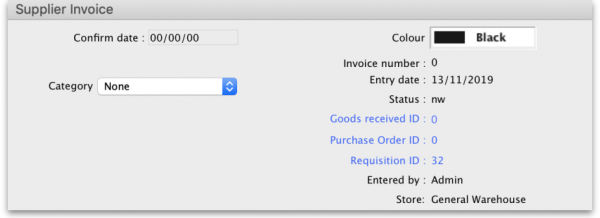

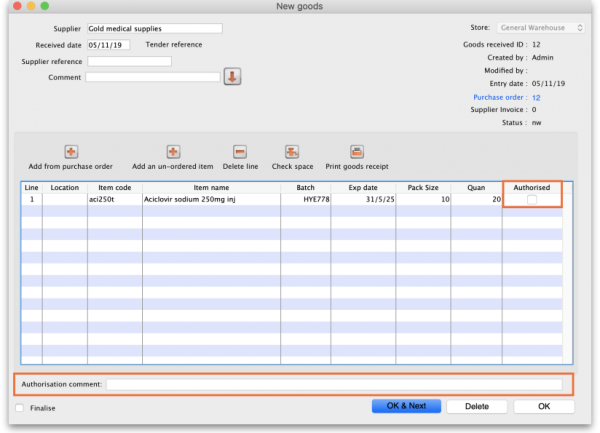

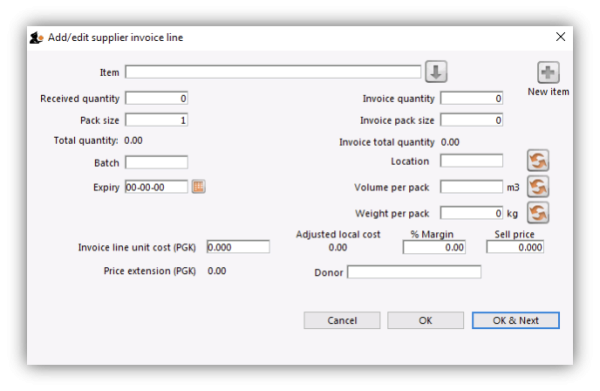

Goods Receiving: Goods Receiving is used to receive stock from an external supplier who we previously ordered stock from via a purchase order. We can then create a Supplier Invoice directly from the goods receipt to add received stock to our inventory.

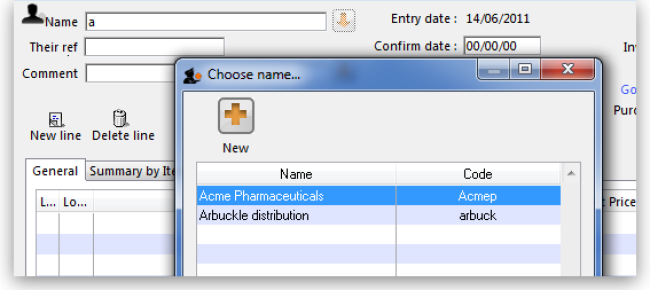

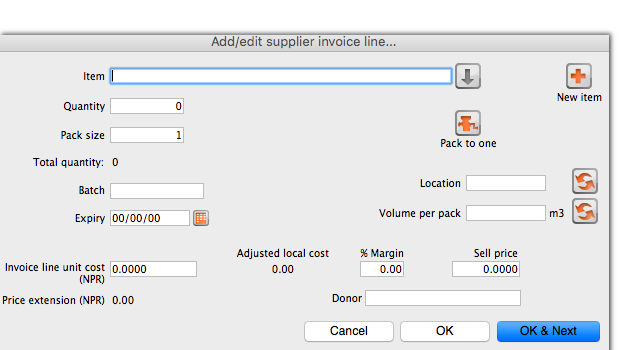

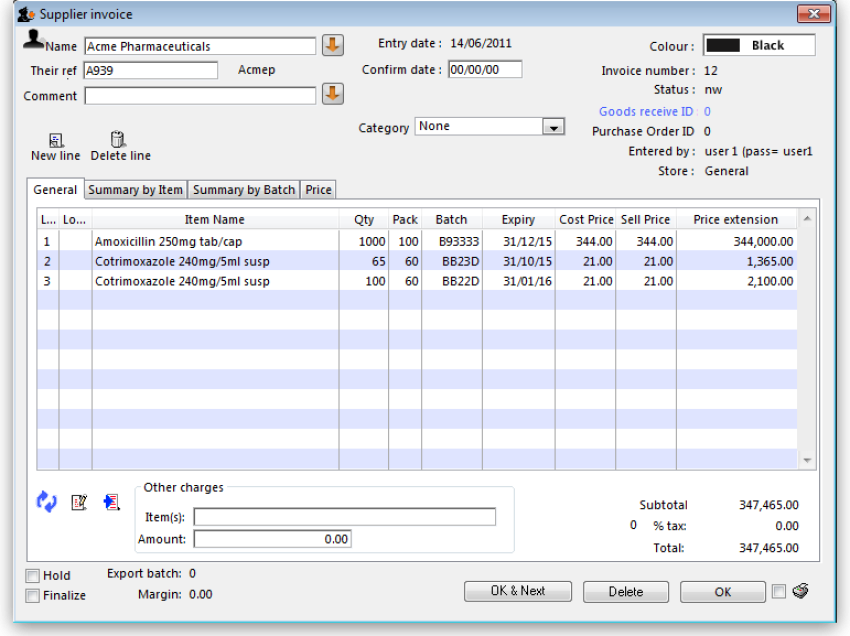

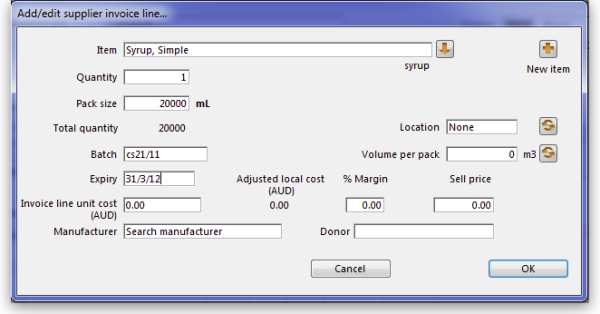

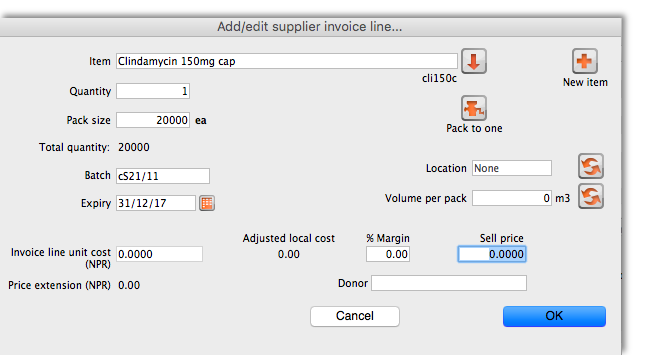

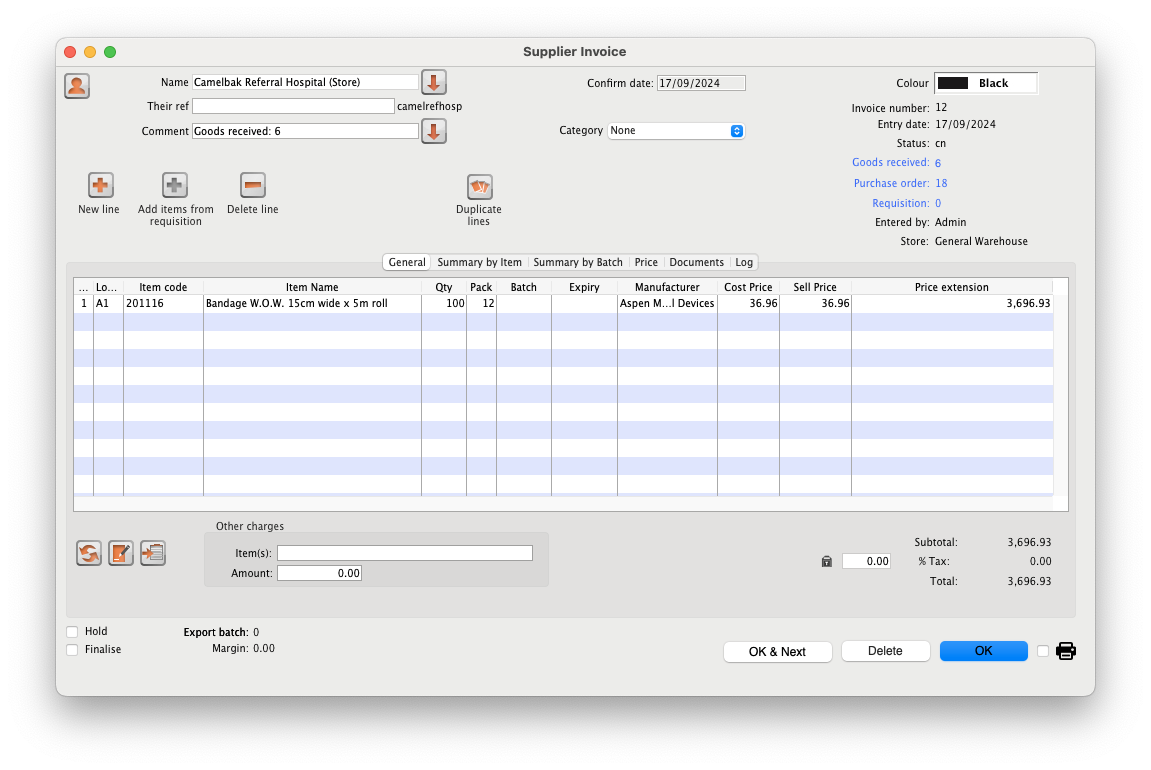

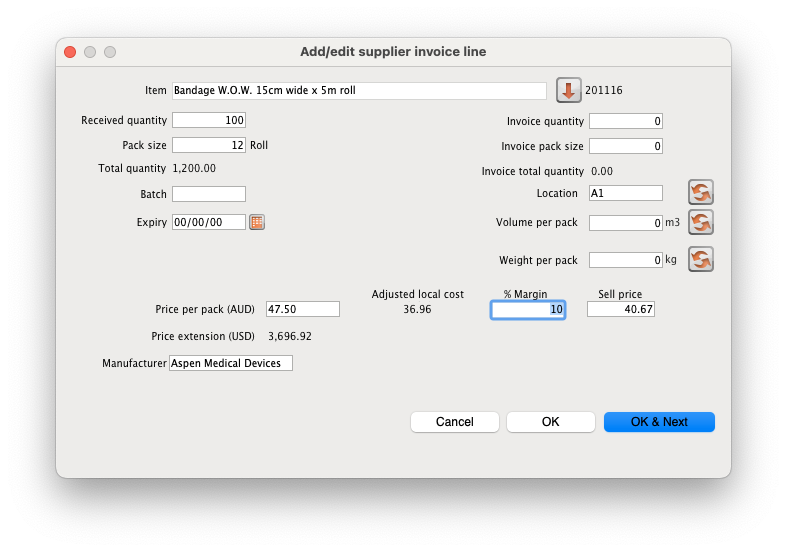

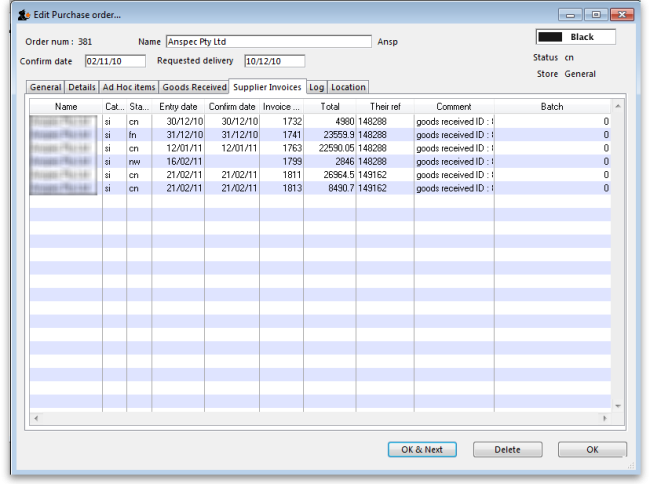

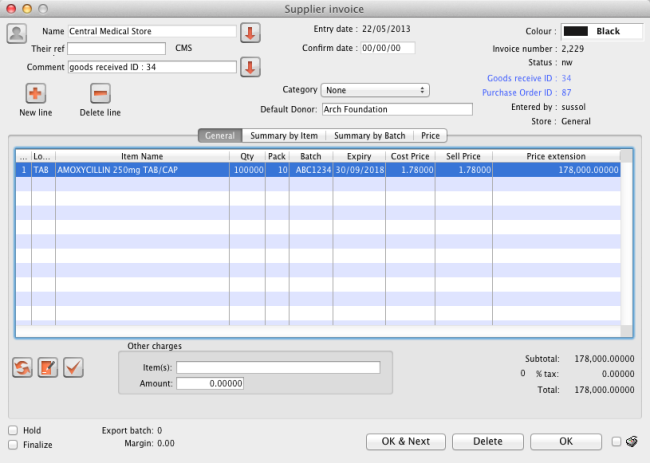

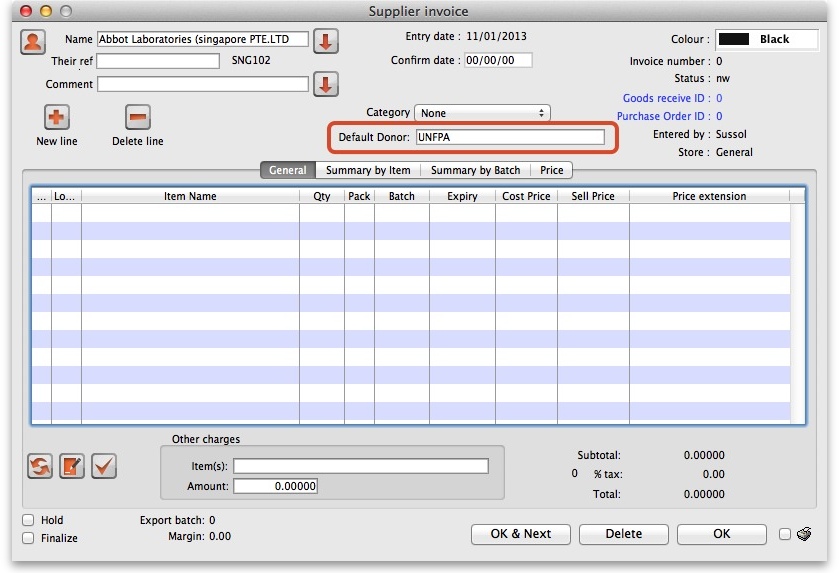

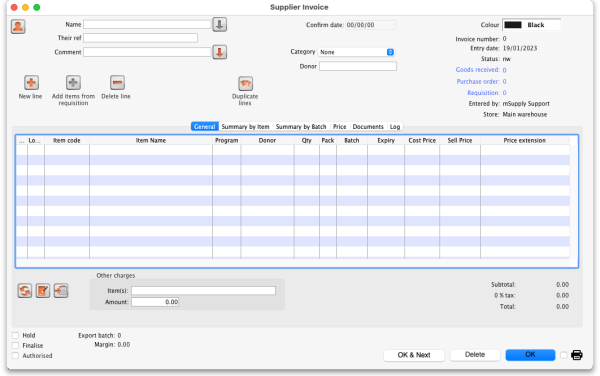

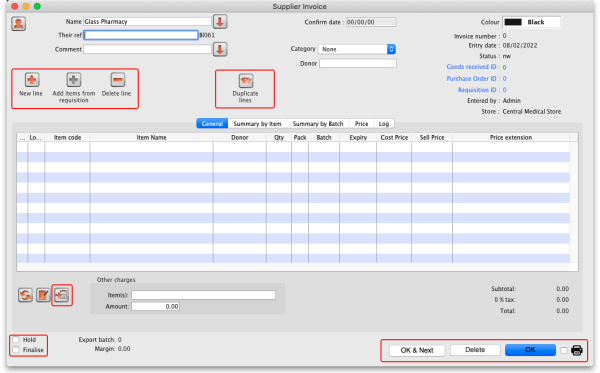

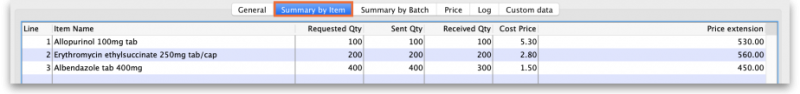

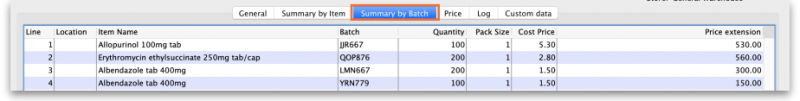

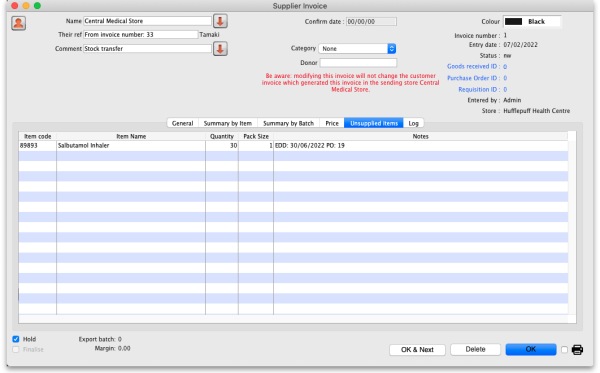

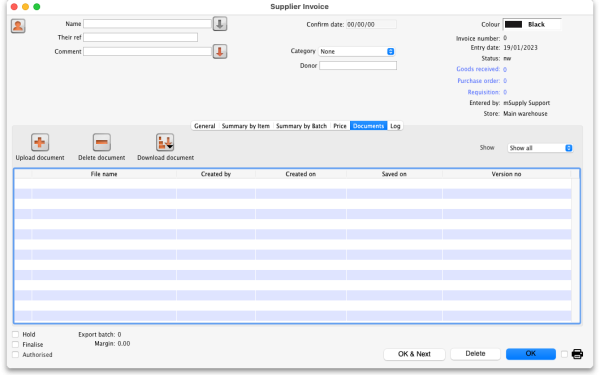

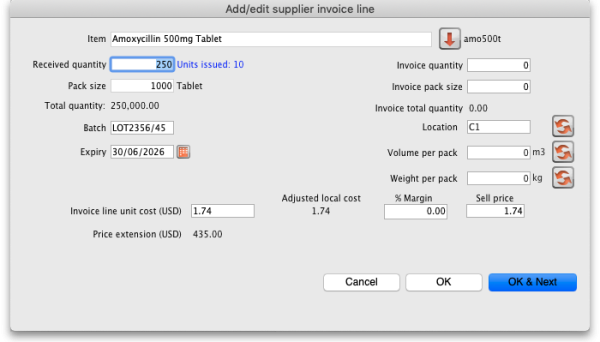

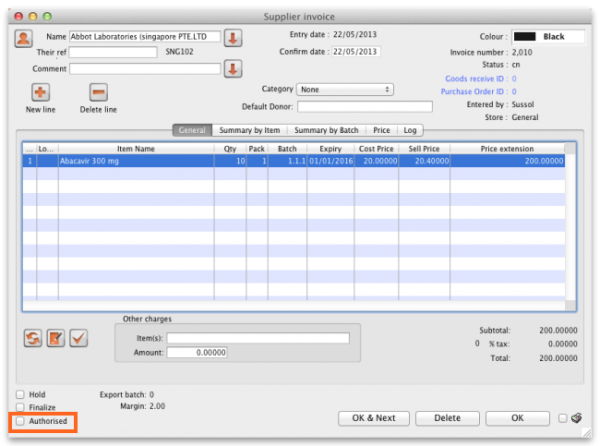

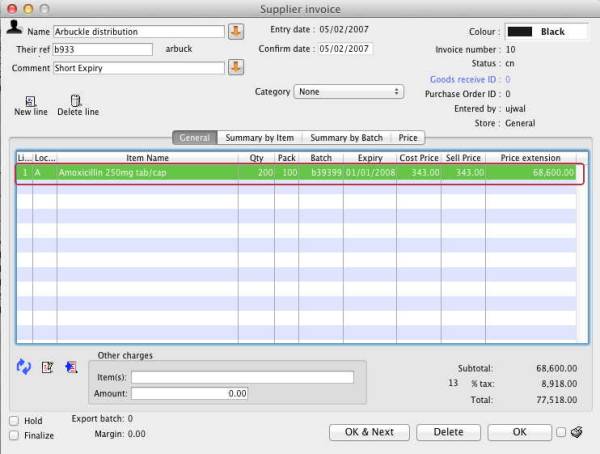

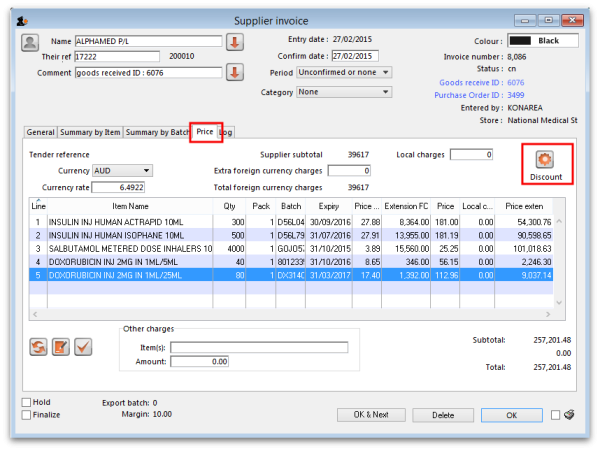

Supplier Invoices: Supplier Invoices are used to add received stock to our inventory. They are also known as “bills”.

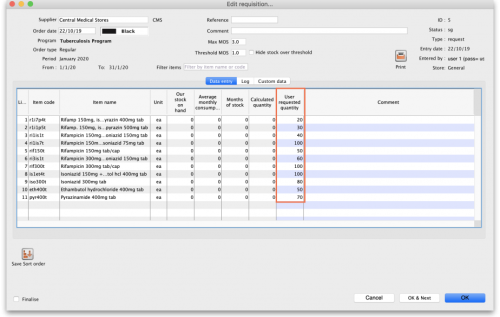

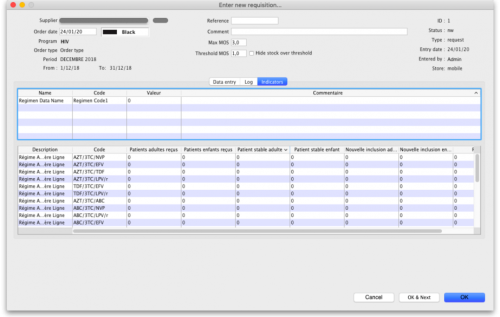

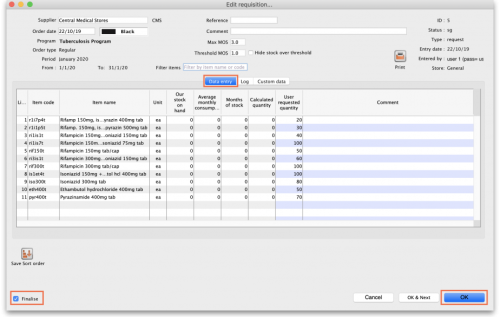

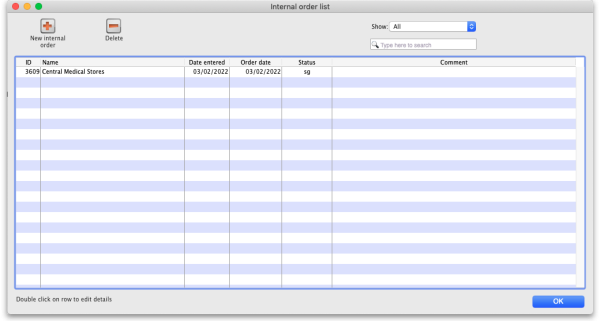

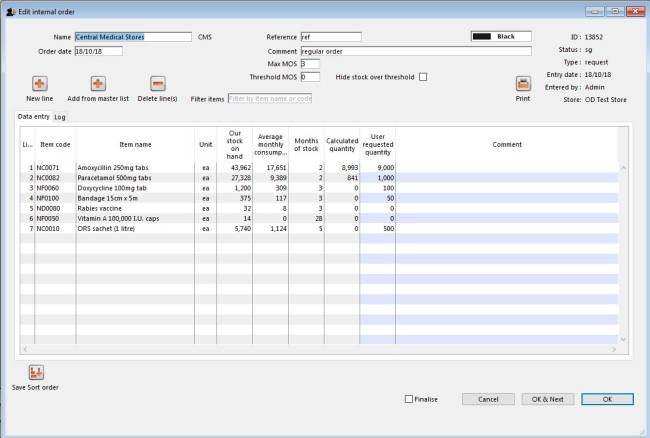

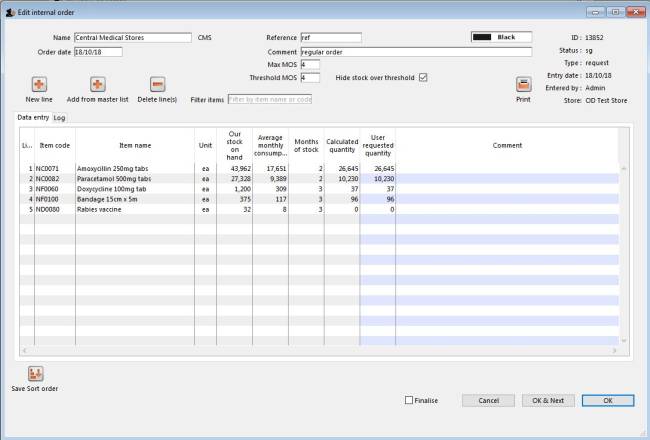

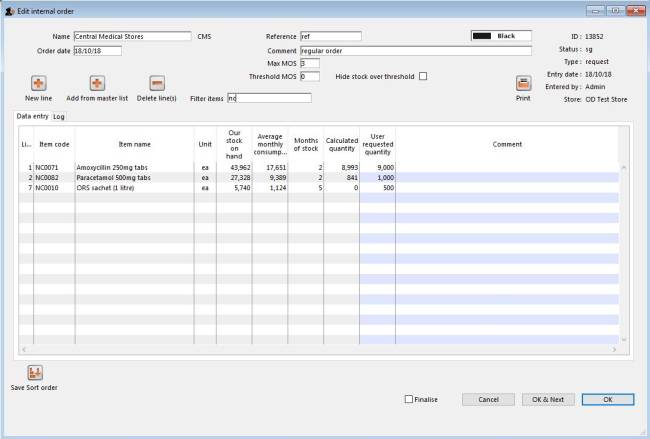

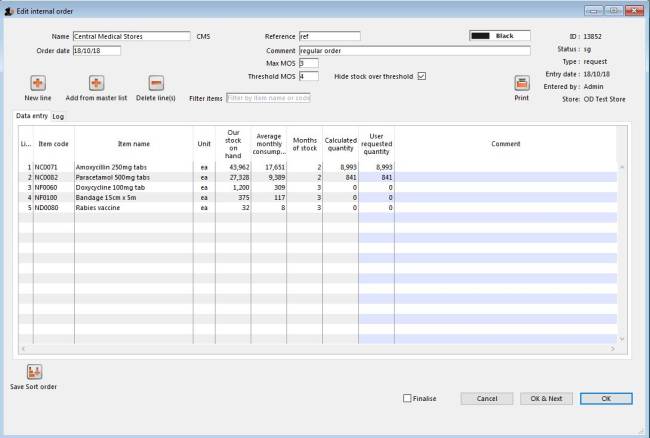

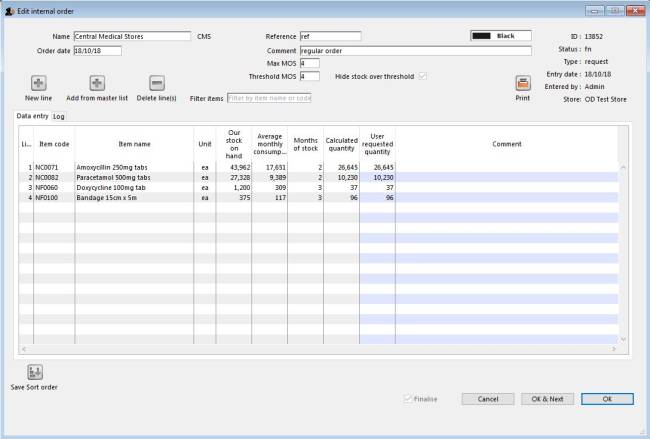

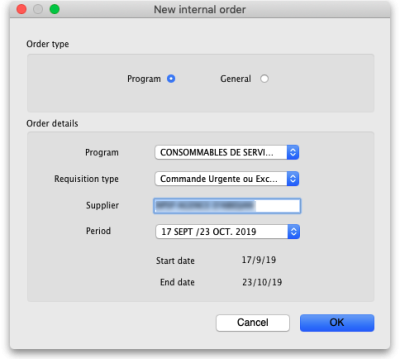

Internal Orders: Internal Orders are used to order stock from an internal supplier i.e. a supplier who does use mSupply (e.g. central medical store, provincial warehouses).

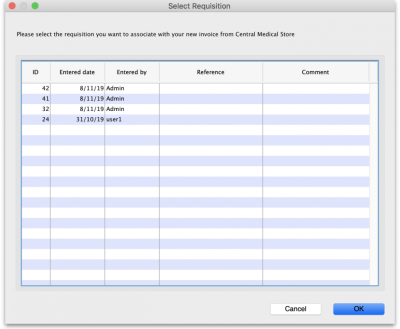

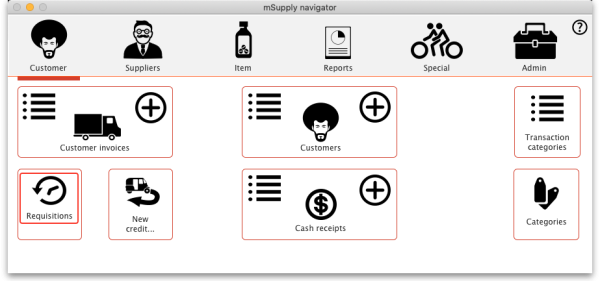

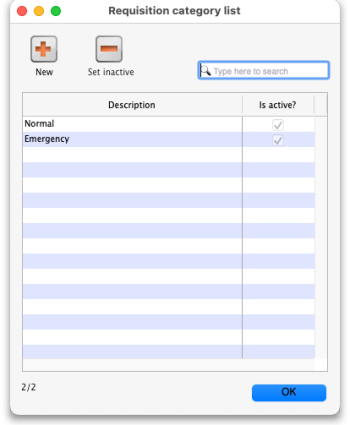

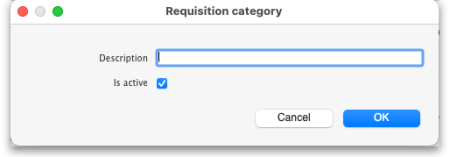

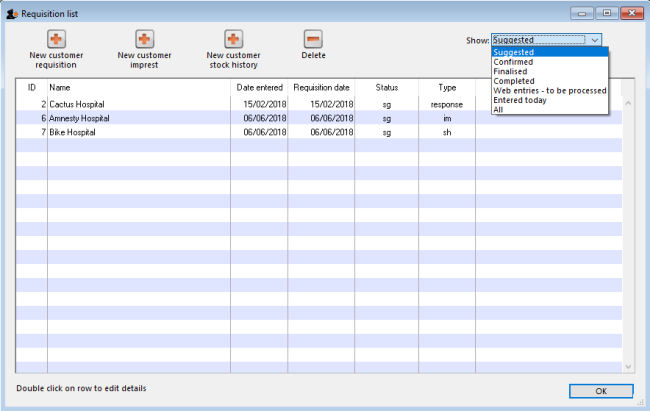

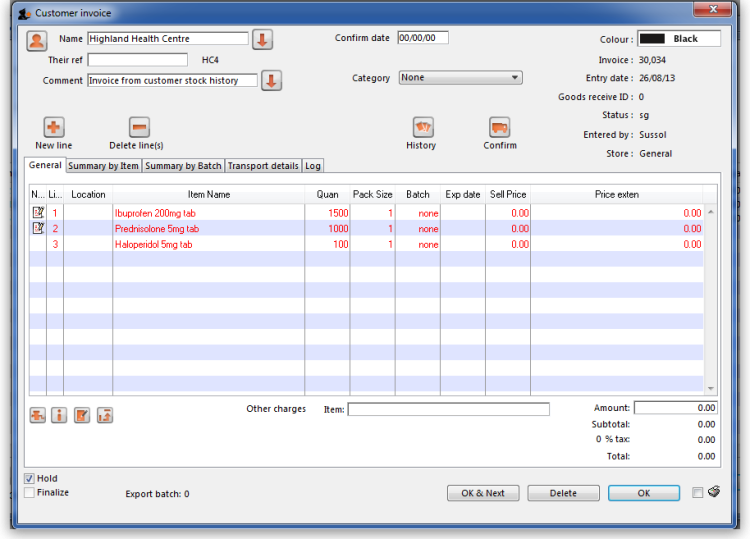

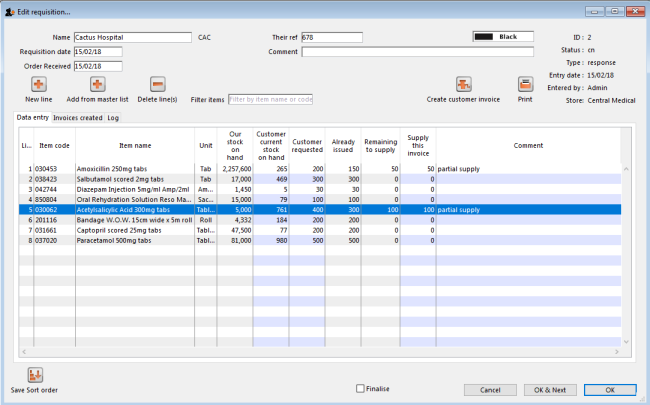

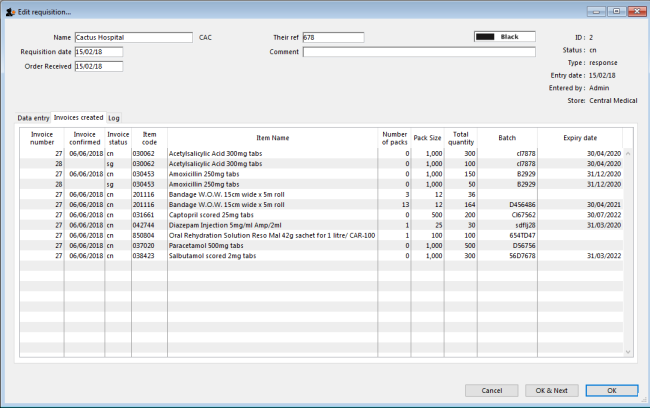

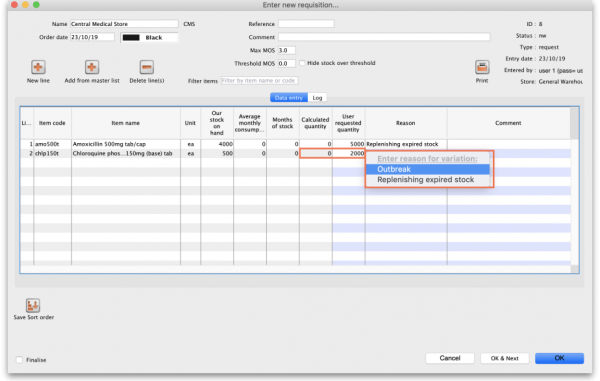

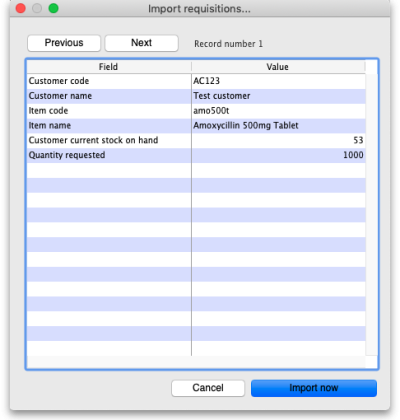

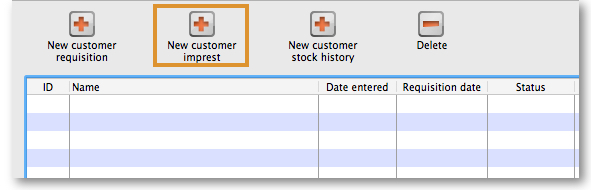

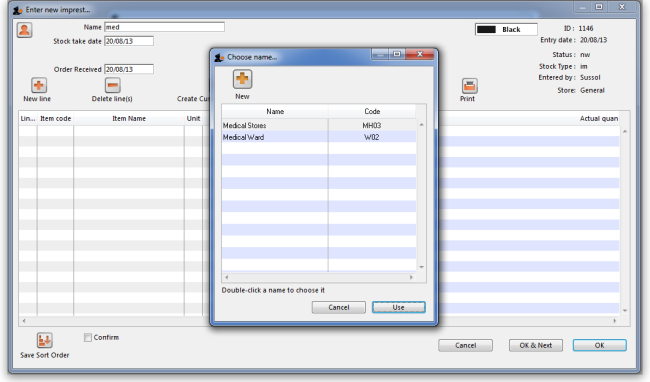

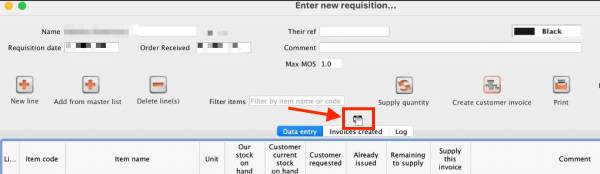

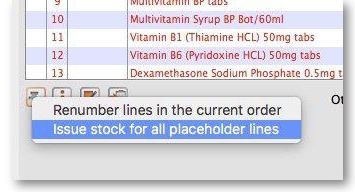

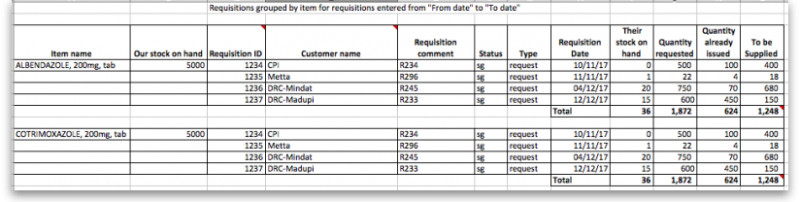

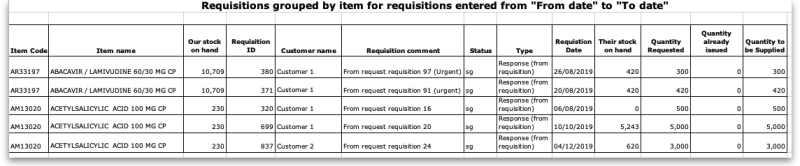

Requisitions: Requisitions show internal orders placed to our store from customers using mSupply. Examples of customers using mSupply include provincial warehouses, public hospitals and health centres. We can create a Customer Invoice directly from the requisition to issue stock to a customer.

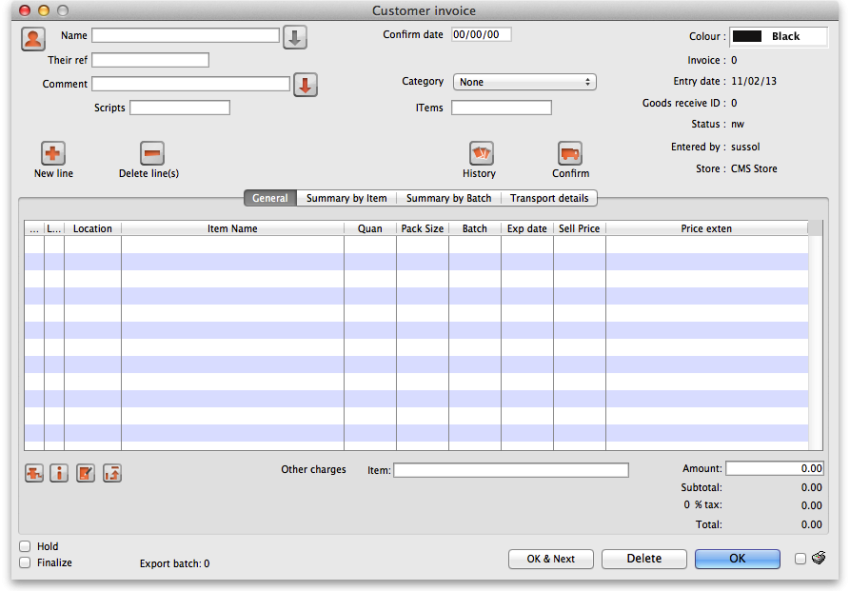

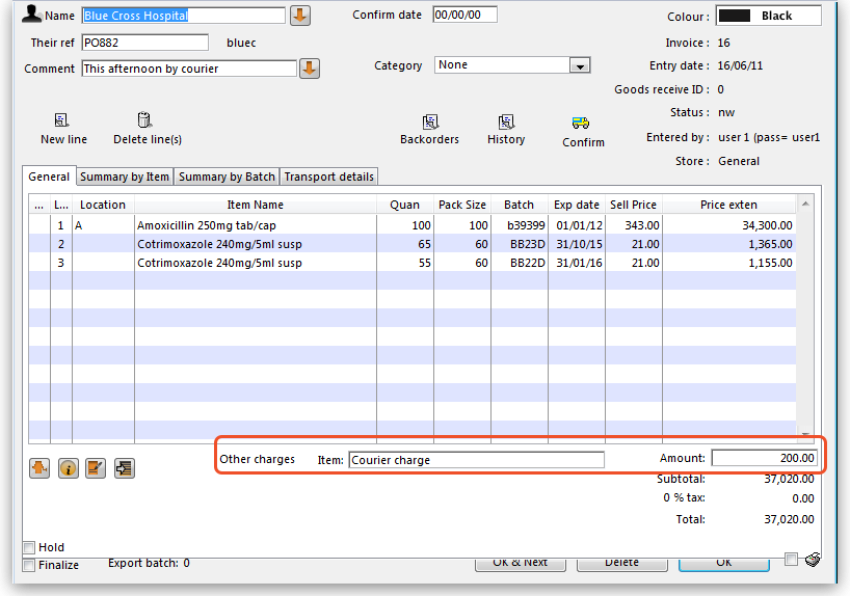

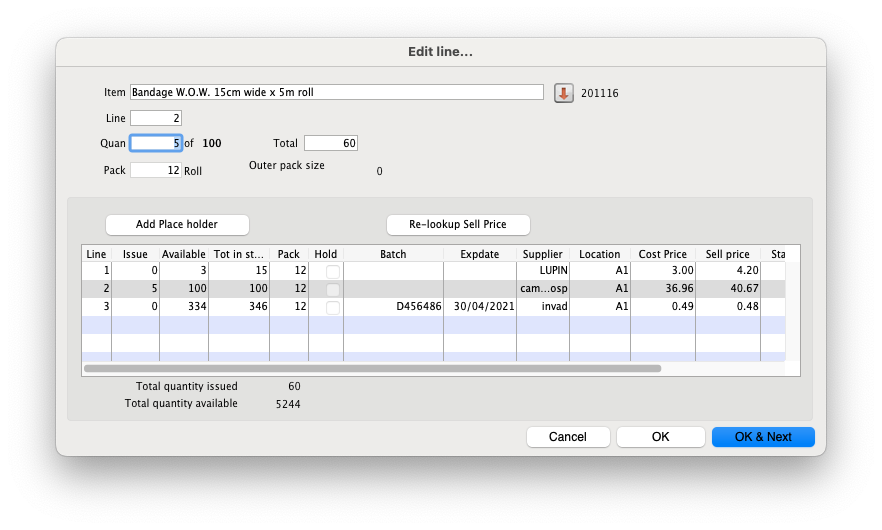

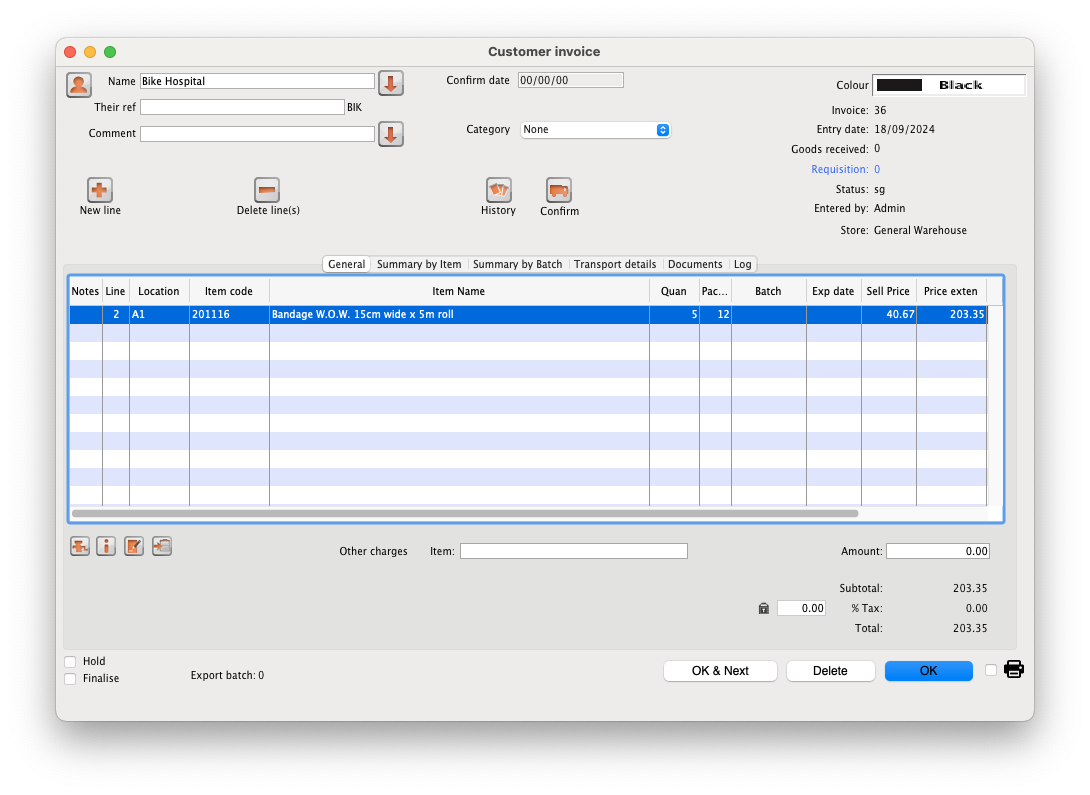

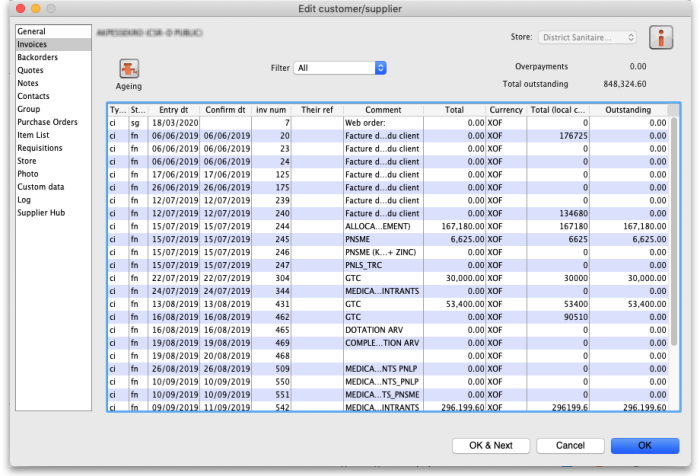

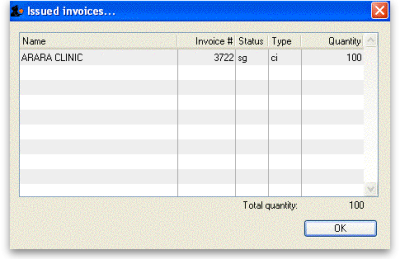

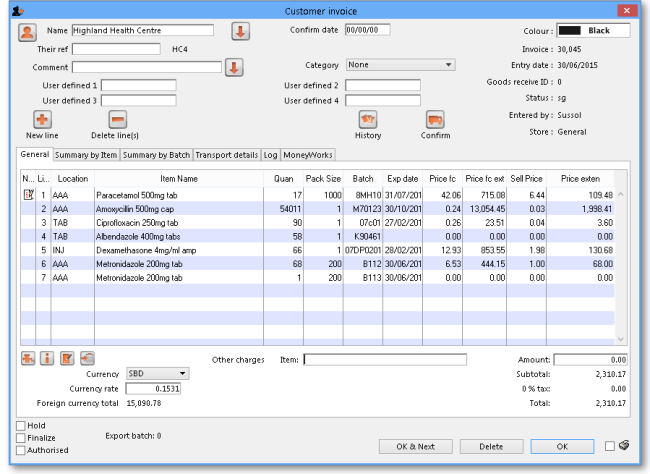

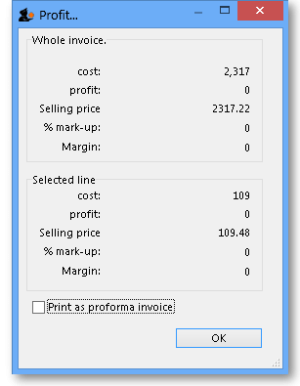

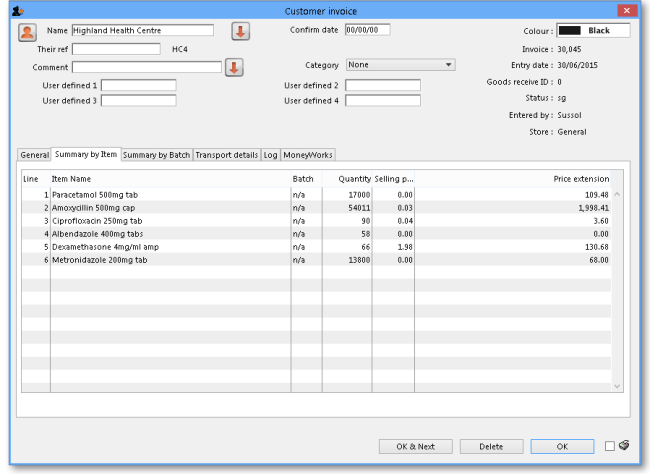

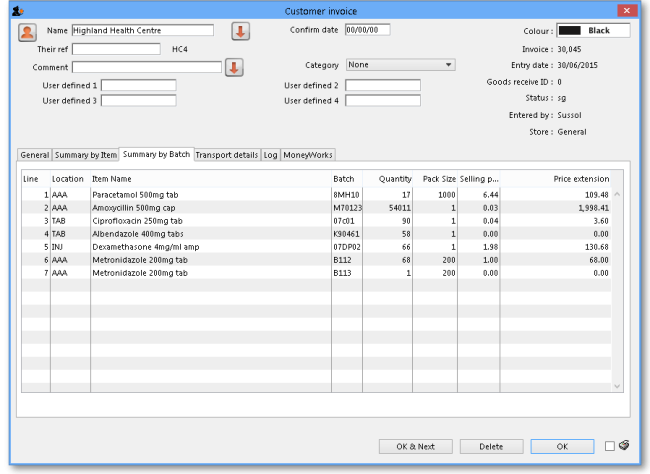

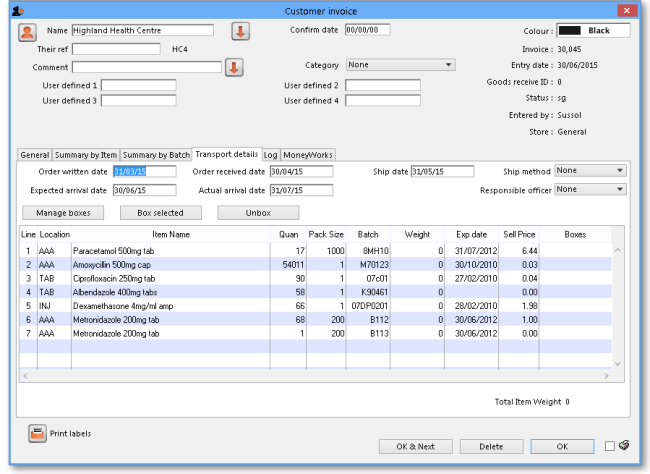

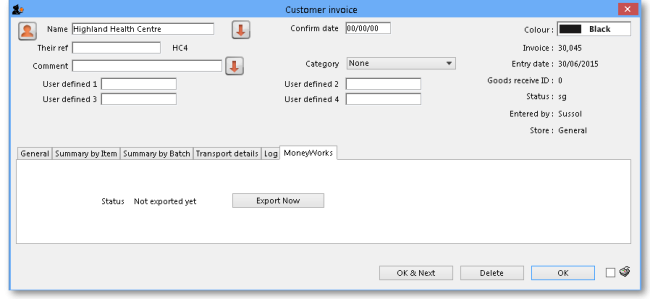

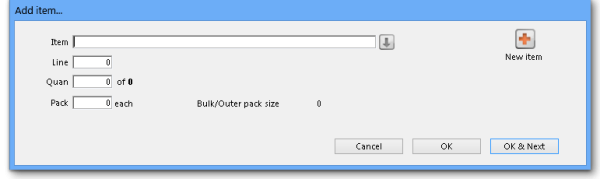

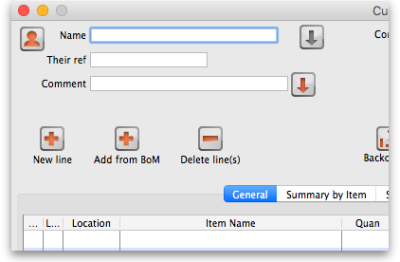

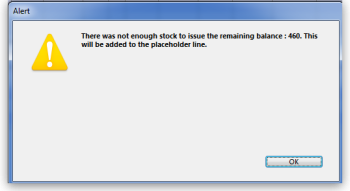

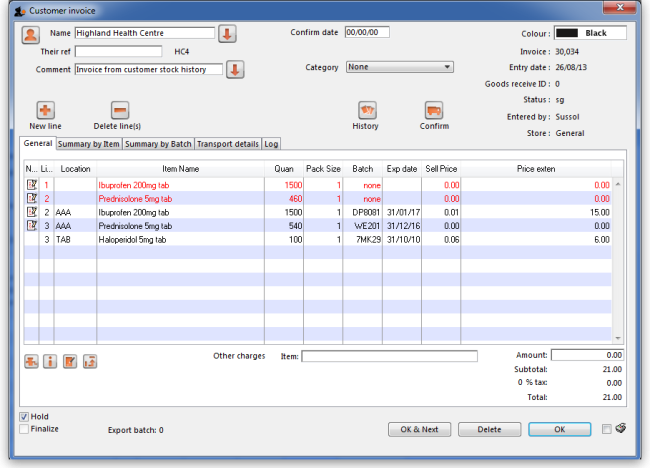

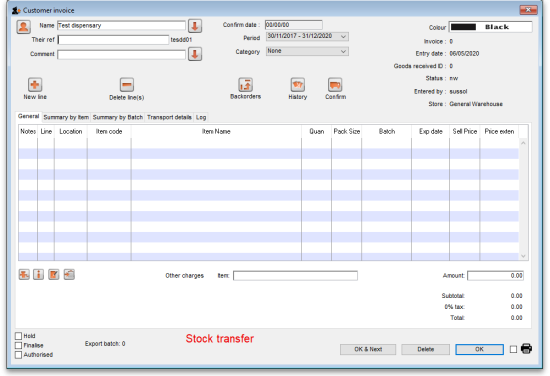

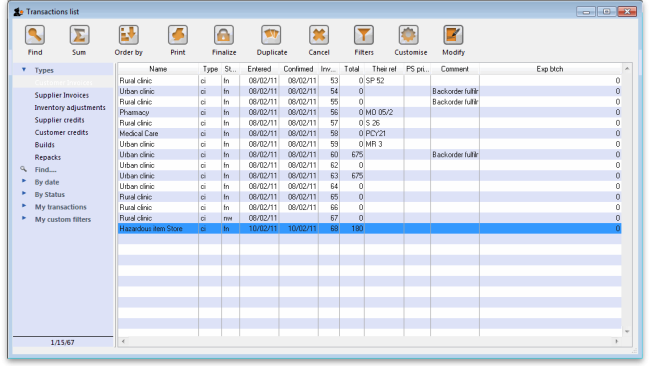

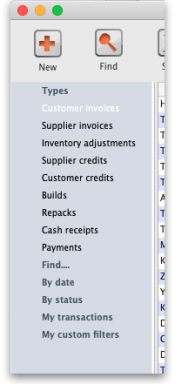

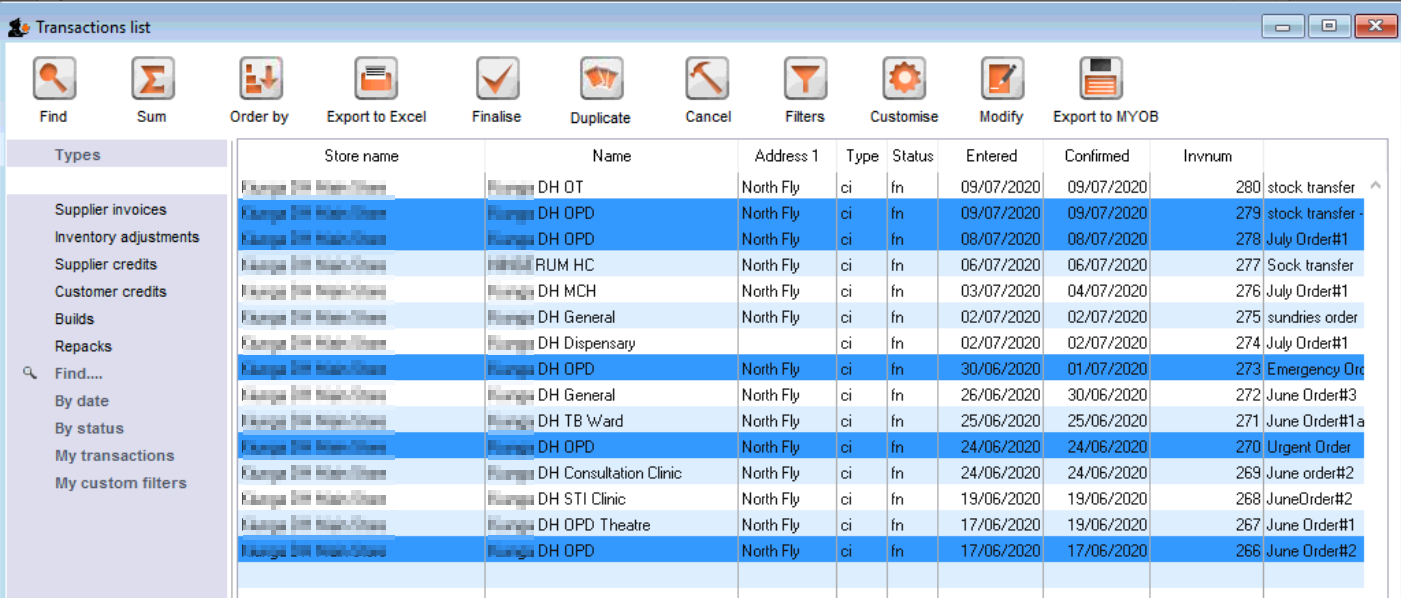

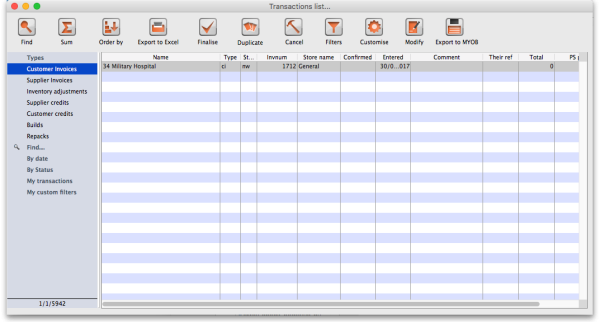

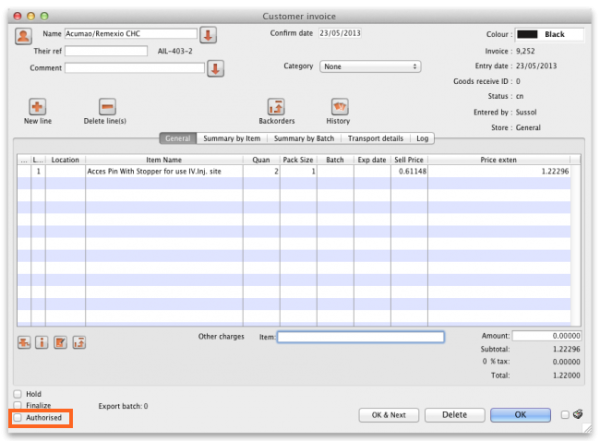

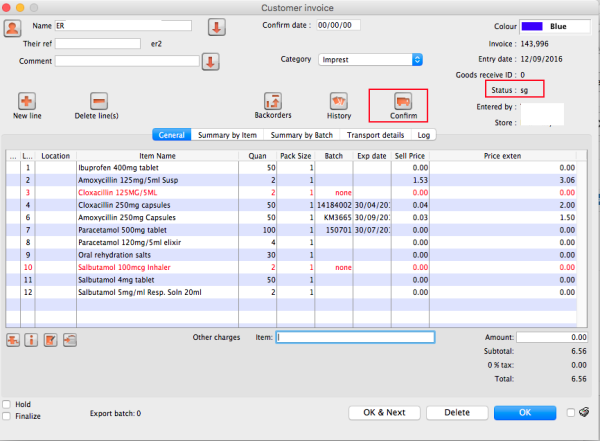

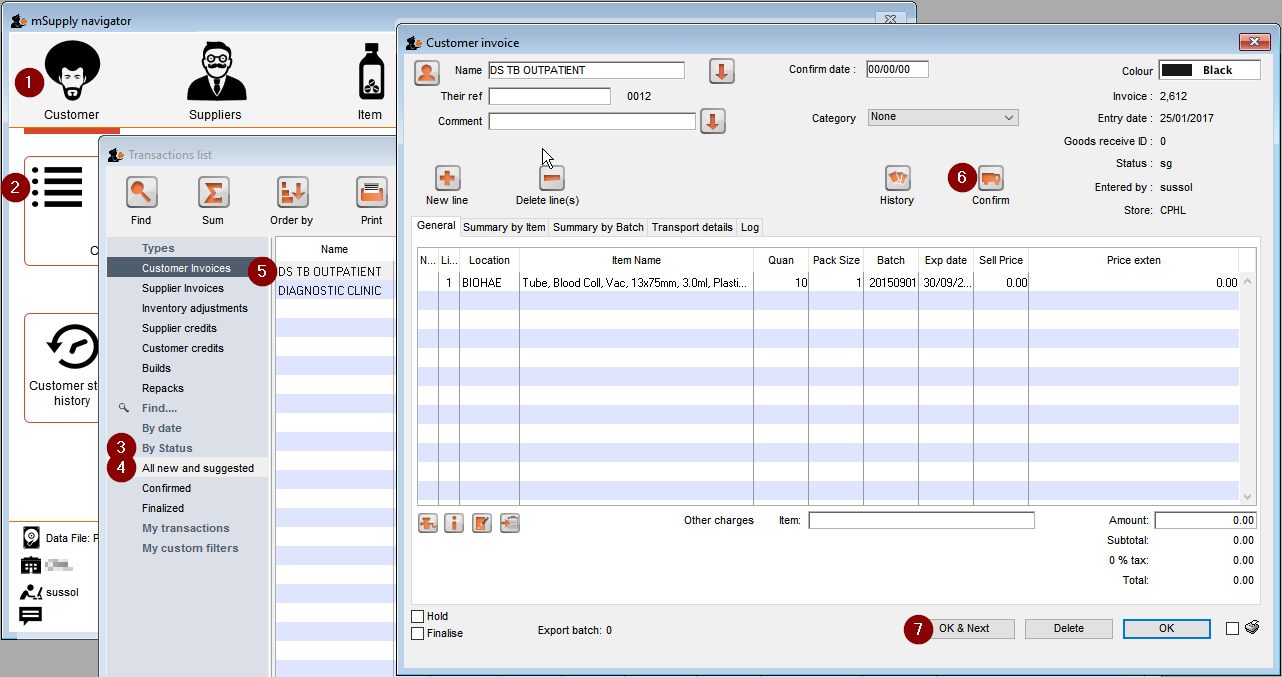

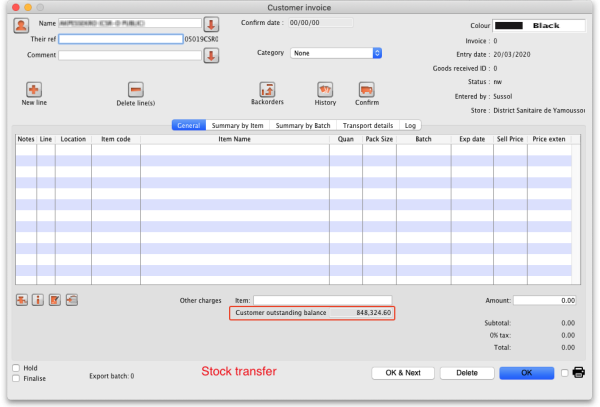

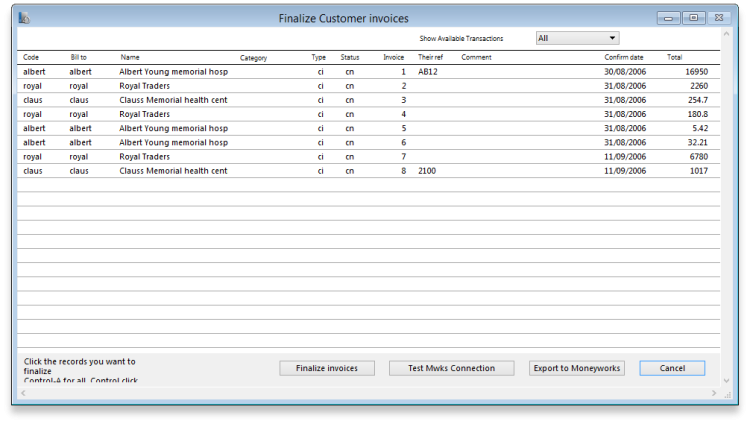

Customer Invoices: Customer Invoices are used to issue stock to a customer from our inventory.

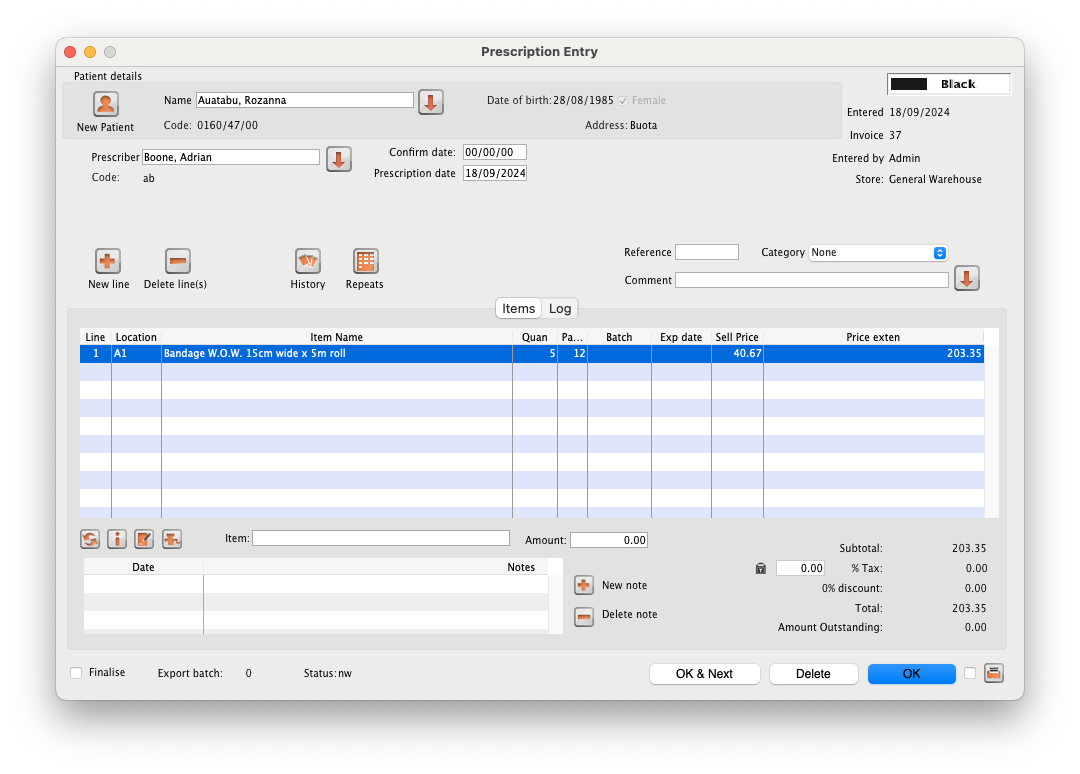

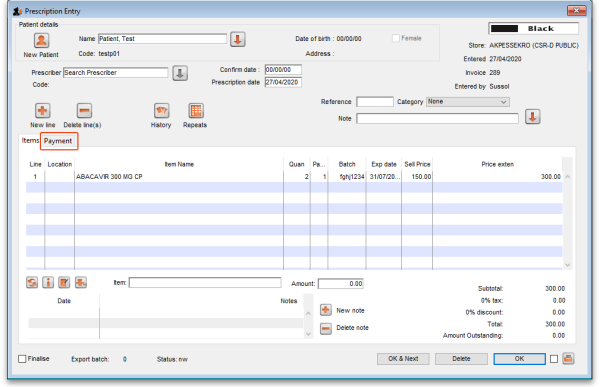

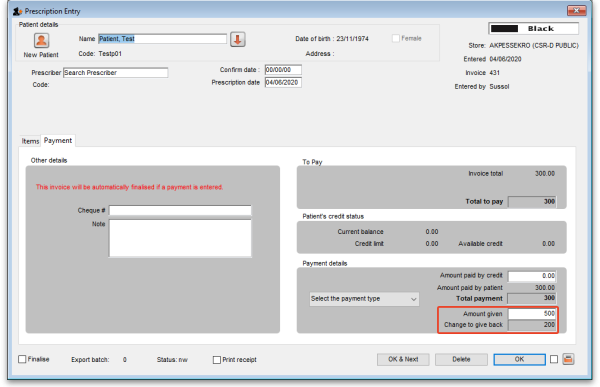

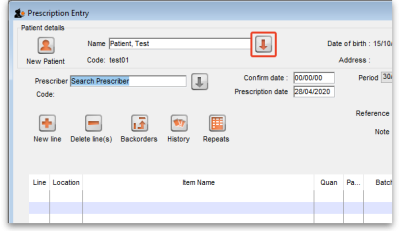

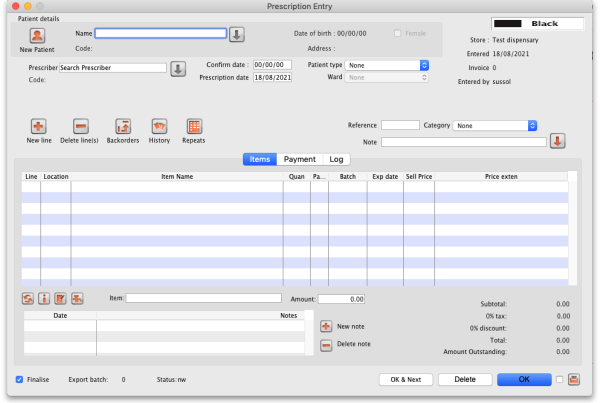

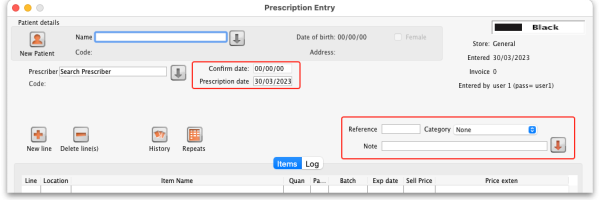

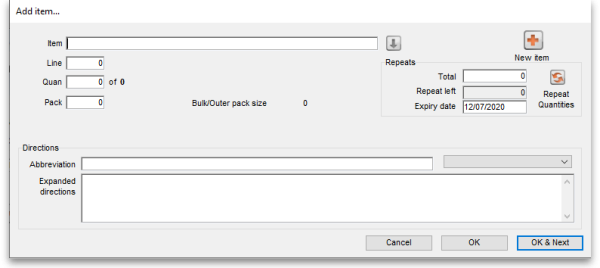

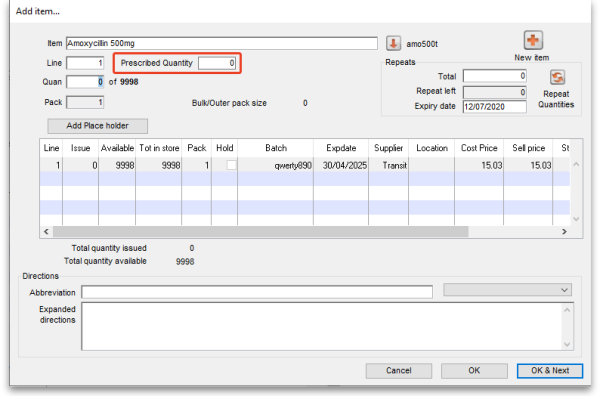

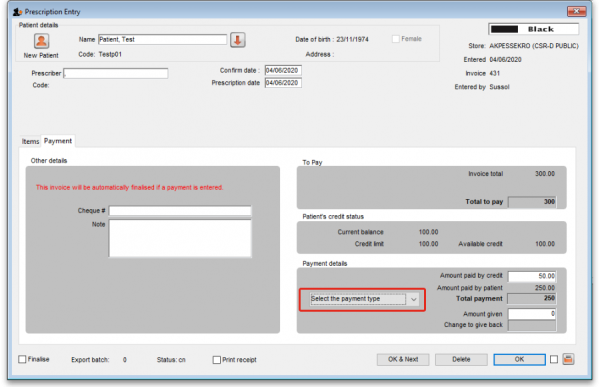

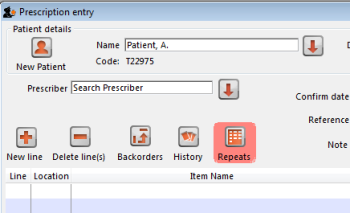

Prescriptions: Prescriptions are instructions written by a prescriber authorising a patient to be provided a medicine or medical device. mSupply can record dispensed prescriptions and maintain patient dispensing histories.

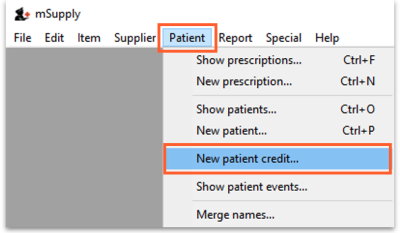

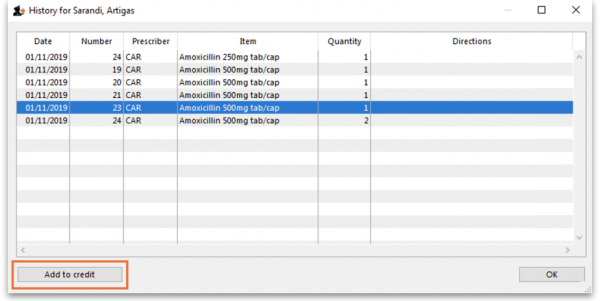

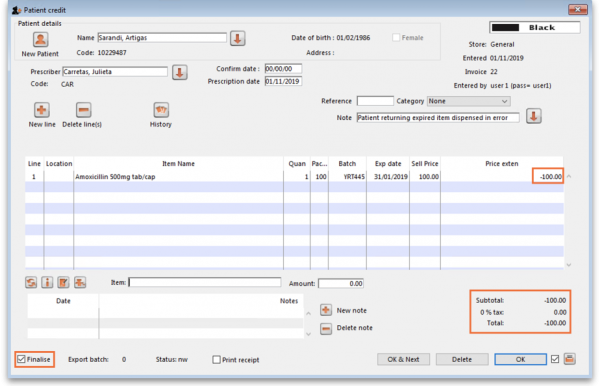

Patient Credits: Patient Credits are used to return items from patients and record credits in their favour. mSupply tracks patient credits and applies them to outstanding prescription payments.

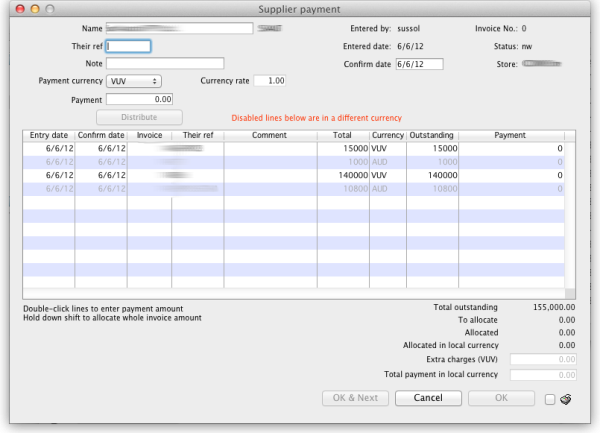

Payments: Payments are used to record payments made to suppliers. mSupply tracks outstanding payments from supplier invoices.

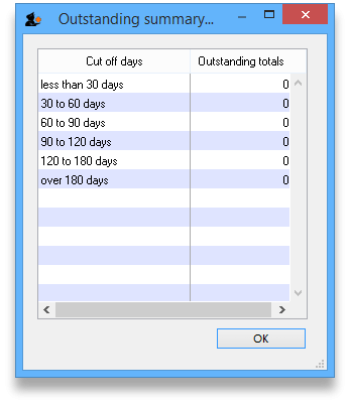

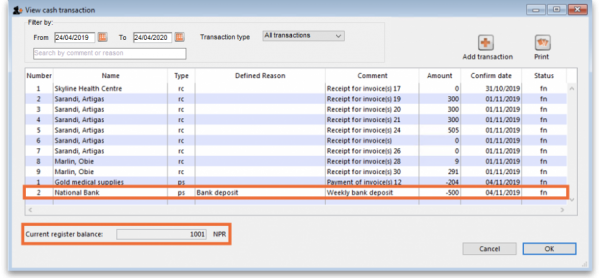

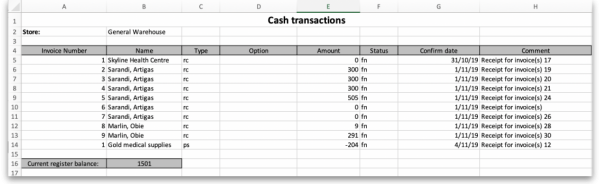

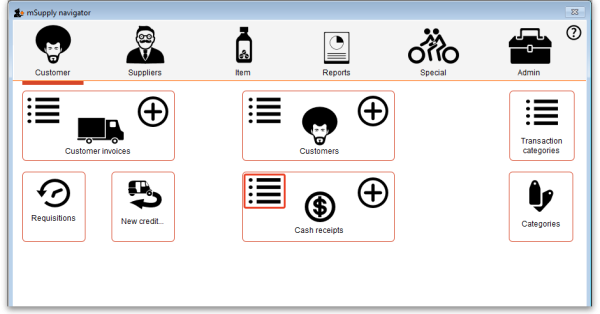

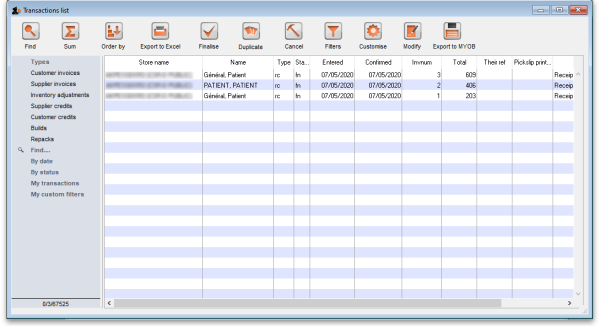

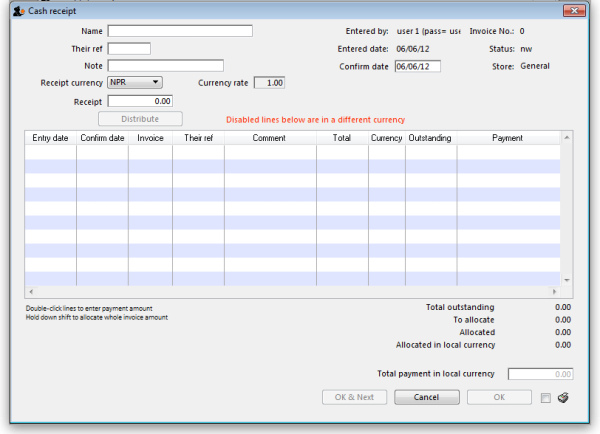

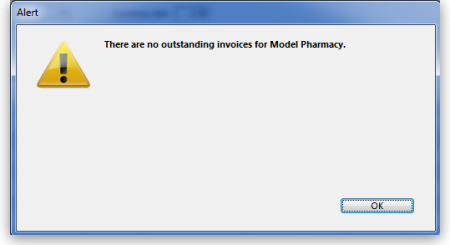

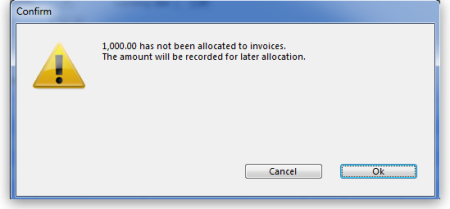

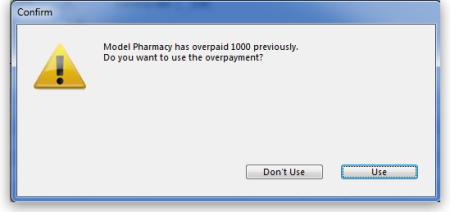

Cash Receipts: Cash Receipts are used to record payments received from customers for customer invoices. They can also be used to record patient payments for dispensed items. mSupply tracks outstanding payments owed by customers and patients.

Supplier Credits: Supplier Credits are used to return items to suppliers and record credits in your favour. mSupply tracks supplier credits and applies them to outstanding supplier payments.

Customer Credits: Customer Credits are used to return items from customers and record credits in their favour. mSupply tracks customer credits and applies them to outstanding customer payments.

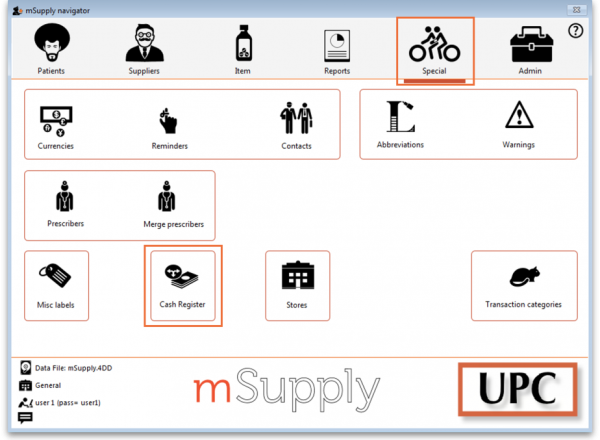

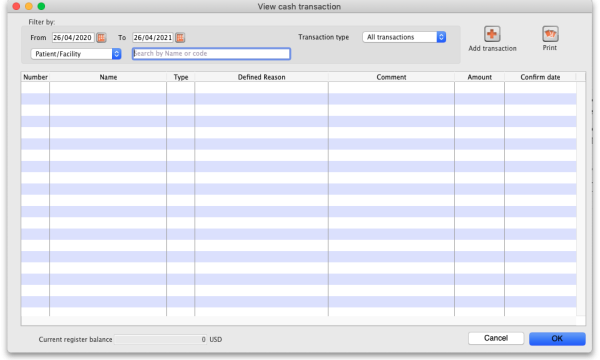

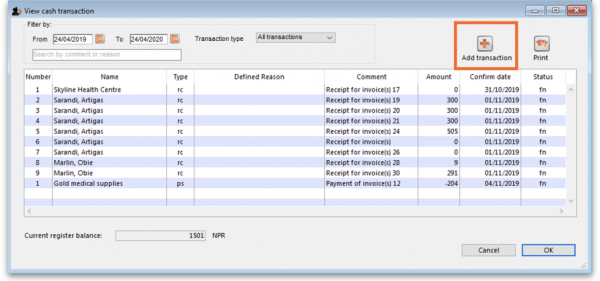

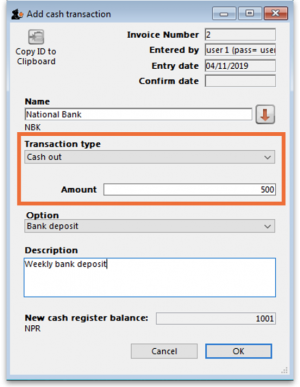

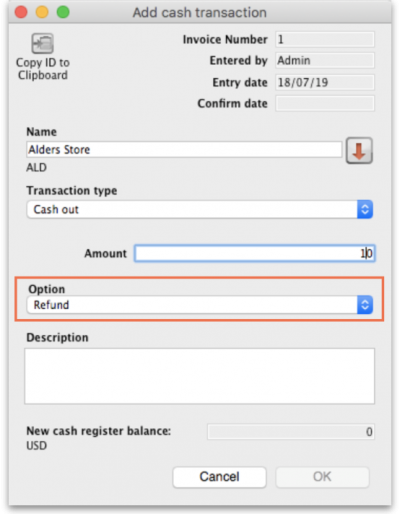

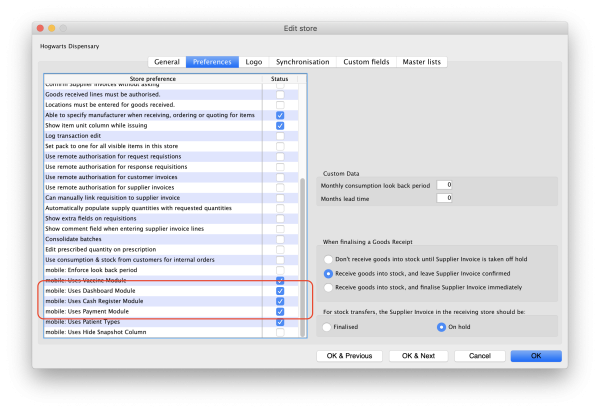

Cash Register: The Cash Register records incoming and outgoing cash transactions and displays a current balance. mSupply tracks all cash movements and records them here.

Configuration

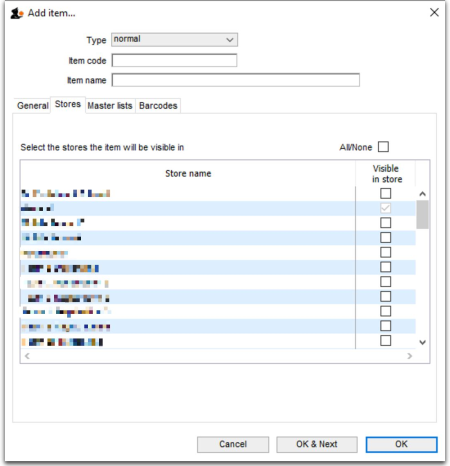

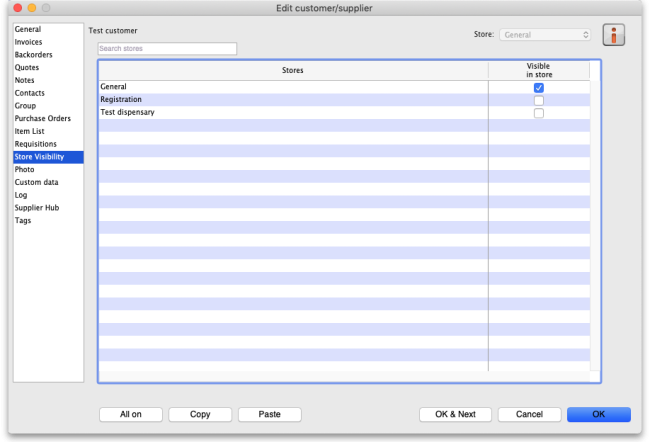

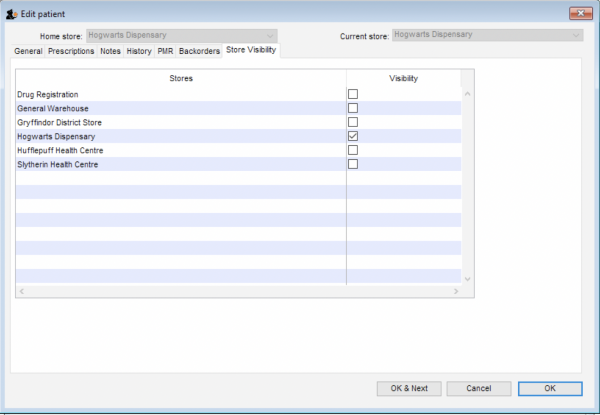

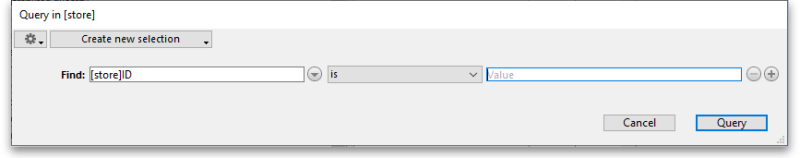

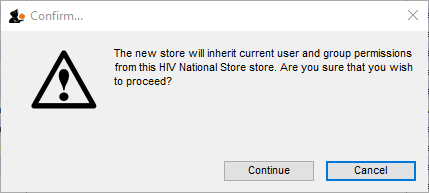

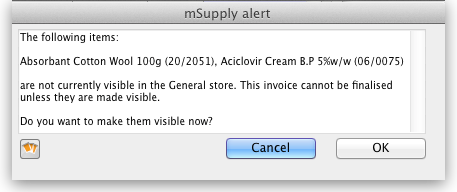

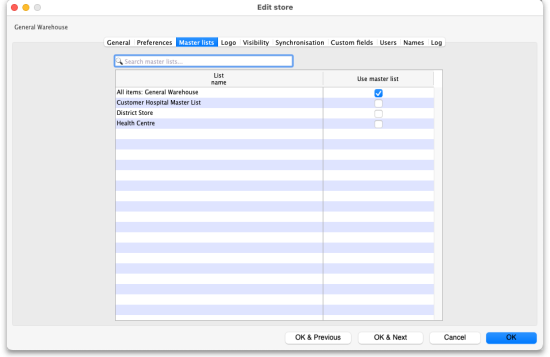

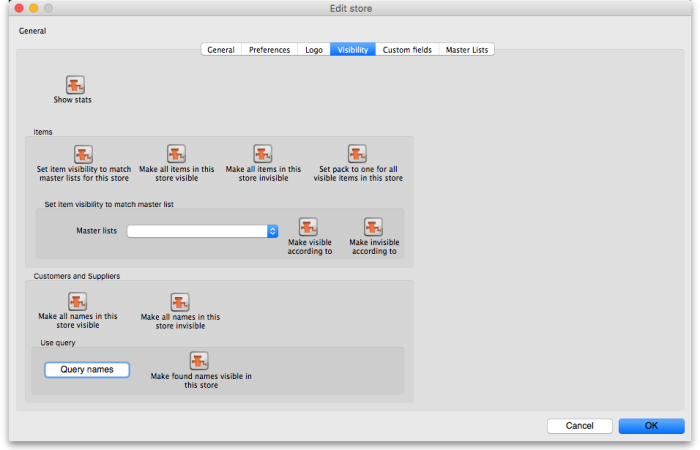

Visibility: Visibility allows us to control what stores, customers, suppliers and items a user can see when logged into a specific store.

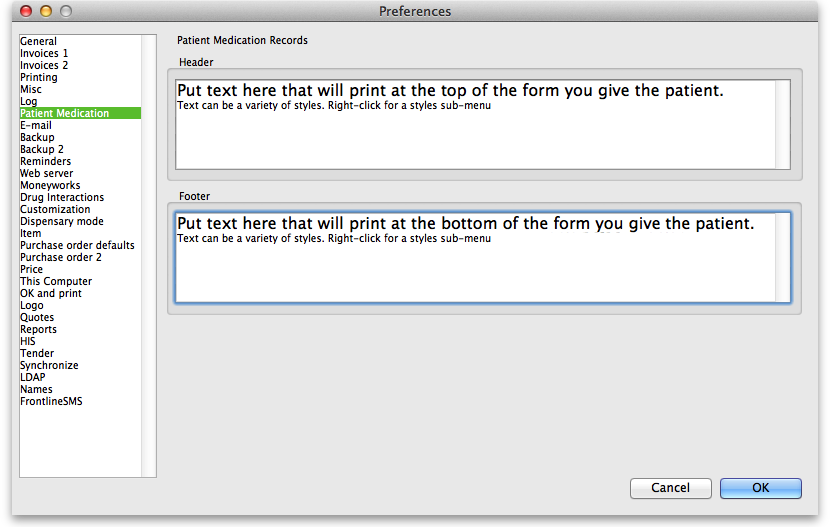

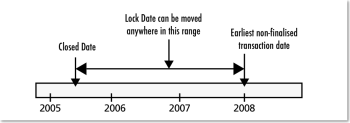

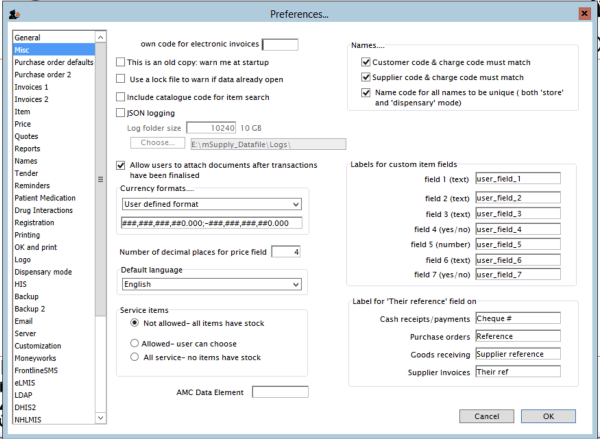

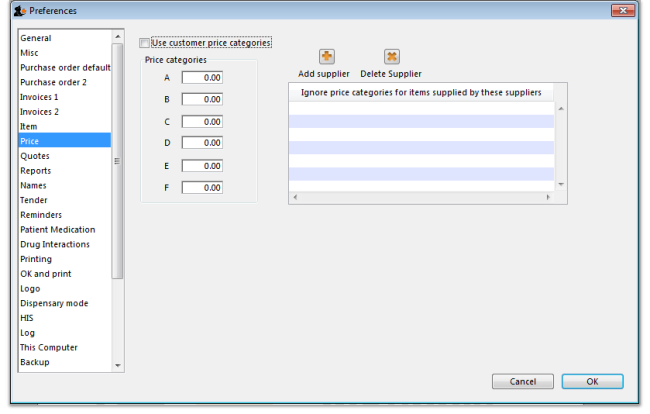

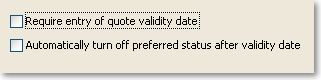

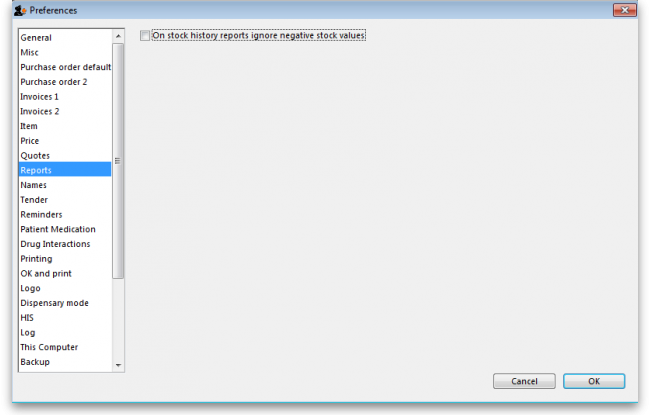

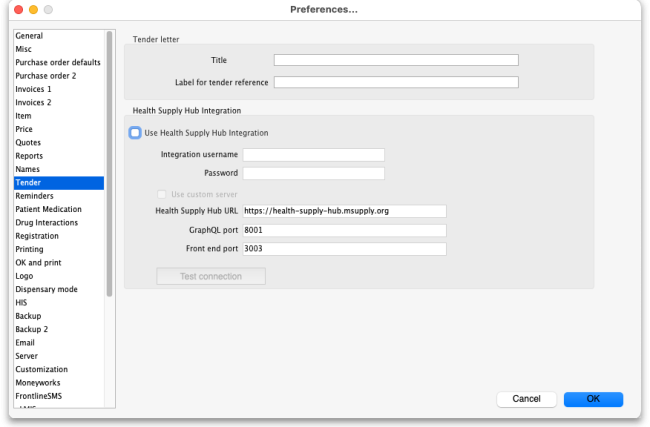

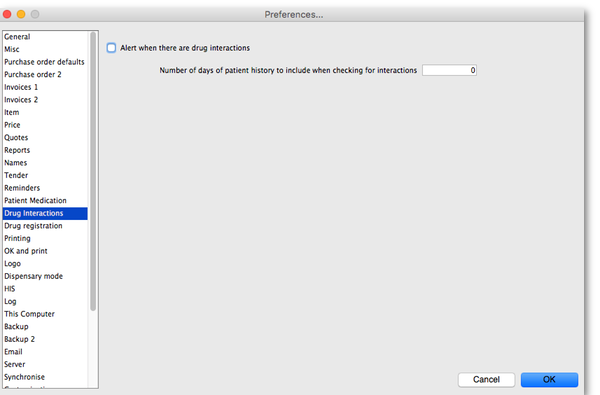

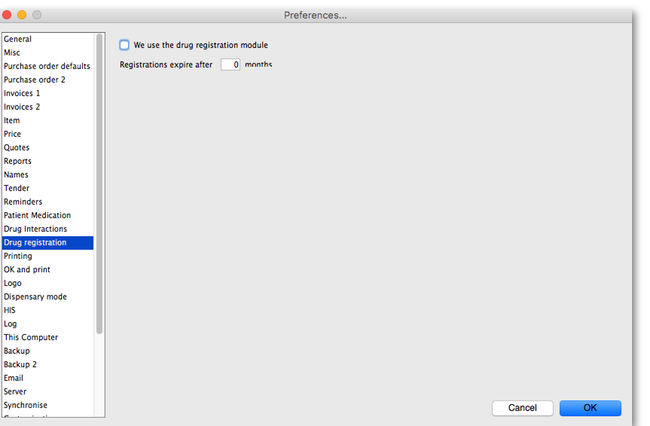

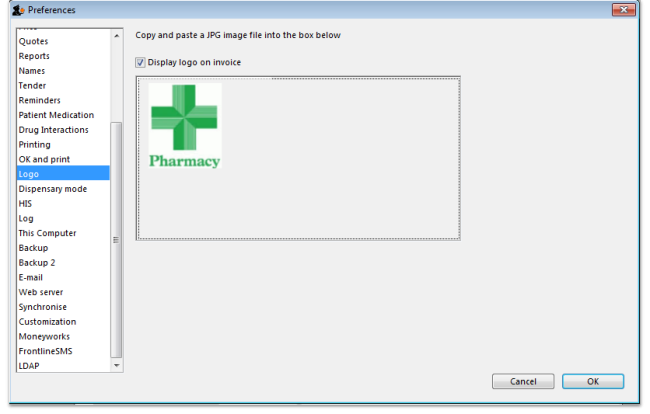

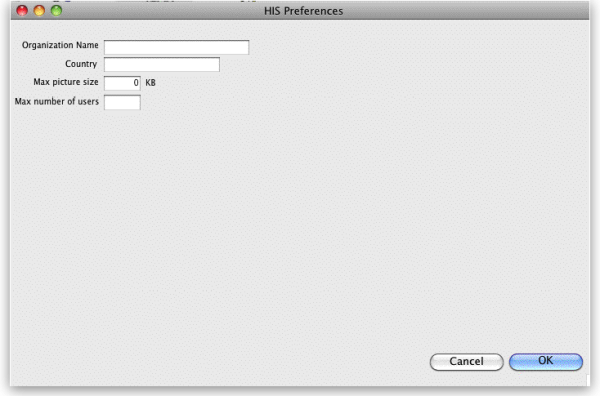

Preferences: Preferences are system-wide settings that apply to all stores and users.

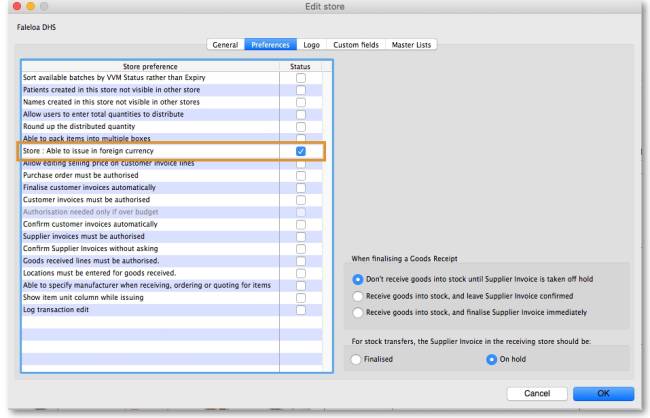

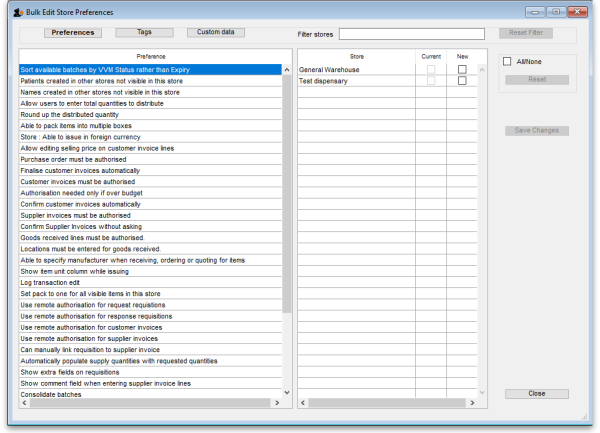

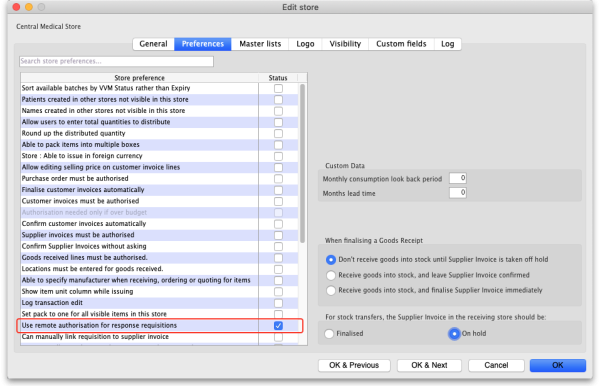

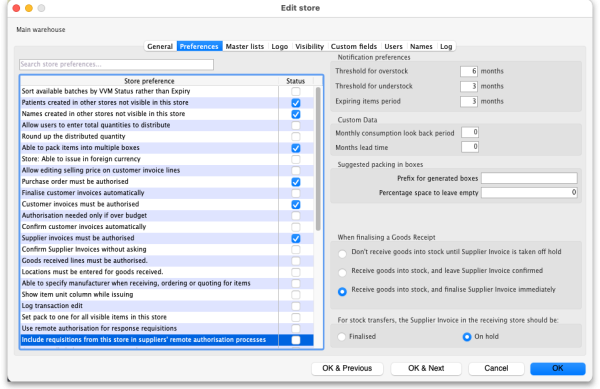

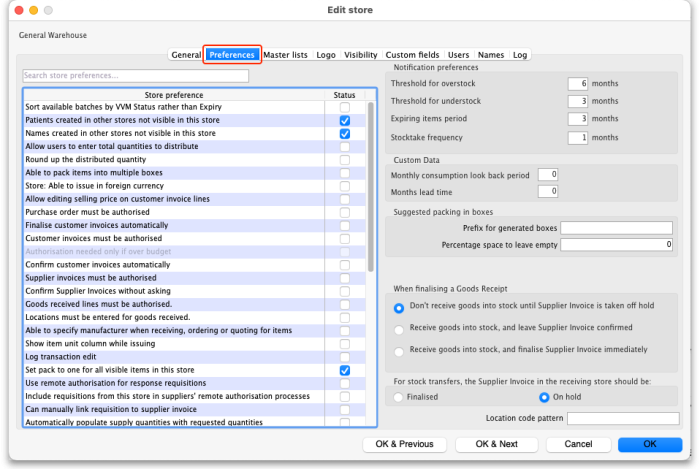

Store Preferences: Store Preferences are settings that apply to specific stores.

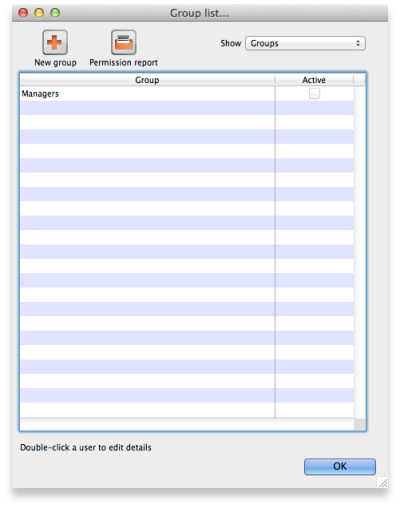

Permissions: Permissions are settings that apply to specific users as either individuals or groups.

1.04. Which combination of mSupply products best suits your organisation?

Since its creation in 1998, mSupply has grown and multiplied as it has been applied to different challenges. The original Free-user (Windows or Mac based) application continues to be downloaded and used regularly. In fact, it comes packed with (almost) all the bells and whistles of some of our most sophisticated installations, but is only suitable for a small, 'single concurrent user' facility.

Comparison of the mSupply products

So which are the right mSupply products for your organisation?

Free-user

- PC or Mac application - Download here. The database resides on the computer that the application has been installed on. It can be used by only one user at any one time.

- Free! You still need to register mSupply with Sustainable Solutions, but we don't charge you for it - and we don't sell your contact details either!

Single-user

- A software license needs to be procured, generally for about 1/3 of the price of a multi-user client, and then Support and UTD on top of that.

Multi-user (Server / client)

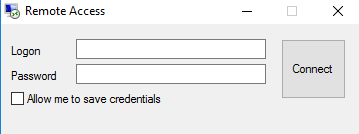

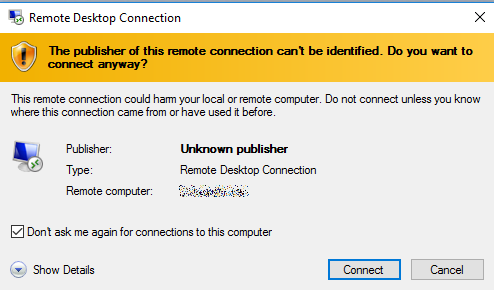

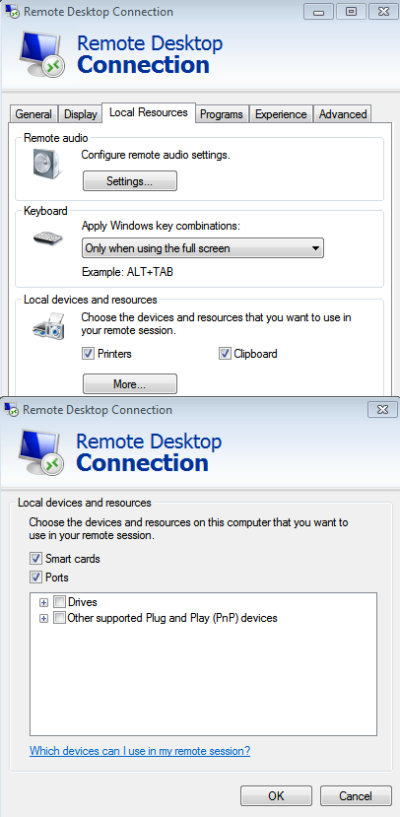

- For situations where more than one user needs to access the database at one time. The database is hosted on a file server and mSupply server software is installed on that hardware. Users have access to this data through mSupply client software installed on client PCs that communicate to the server through a Local Access Network (LAN). Remote users can access the server through Remote Desktop Protocol (RDP) or similar.

- A software license needs to be procured for each concurrent client. Support and UTD is optional, but highly recommended. Most of our customers are very happy to pay for these services.

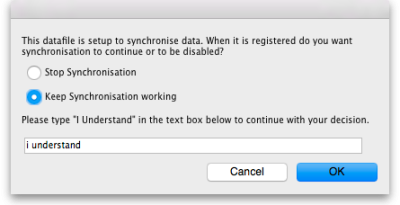

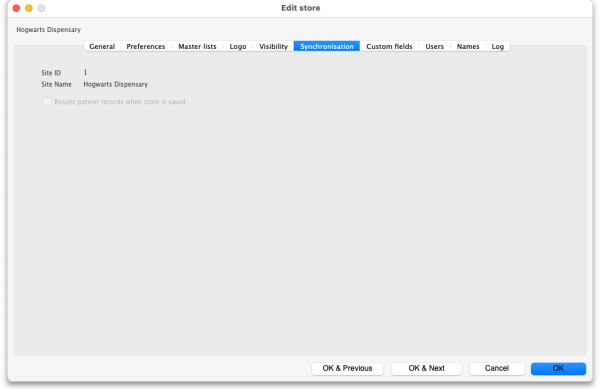

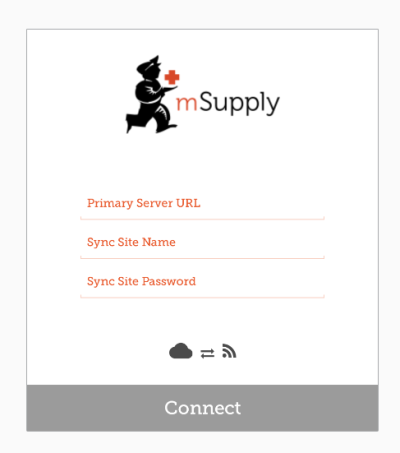

Synchronised Multi-user

- If the internet connection to remote users in a Multi-user configuration is inadequate, then synchronisation allows a Primary - Satellite configuration to be deployed. 'Satellite' multi-user servers are installed at remote sites where users operate mSupply on their local store without worrying about the internet connection. In the background, these 'satellite' servers will synchronise their local store data with a 'Primary' server when the internet connection becomes adequate.

- A software license needs to be procured for each concurrent client for each server. The Synchronisation server Module and Web Server Module are required on the central server.

Synchronised Single-user (Single-user sync)

- There are situations where the remote sites (with poor internet access) are just single-operator stores needing to manage and report their stock using the fully featured mSupply client. Procuring the minimum multi-user satellite server configuration for each of these sites would be expensive. A solution has been developed that entails installing single-user client machines (normally laptops) at these remote locations and then synchronising them to the primary server much like the Synchronised Multi-user configuration.

- Lower cost than conventional synchronised multi-user as the single-user client license is less costly than multi-user client licenses. The Synchronisation server Module and Web Server Module are required on the central server.

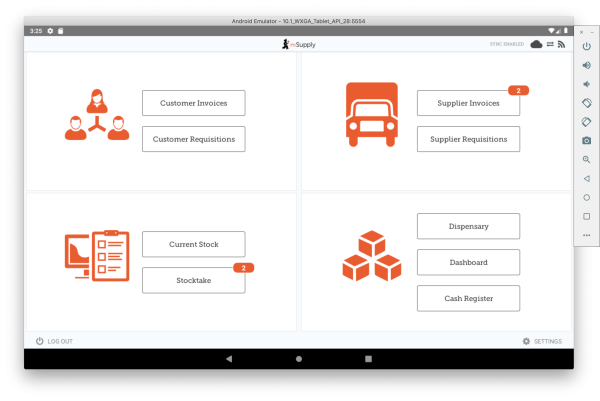

mSupply Mobile (Android)

- mSupply Mobile is similar to Synchronised Single-user (Single-user sync), but the users operate with mSupply Mobile (client) software on Android tablets. This app has a reduced feature set, but is more than adequate for most Last-Mile needs. Local stock details are synchronised back to the Central server, and can be monitored and reported on there.

- Being Open Source software, mSupply Mobile has zero license fees. The Synchronisation server Module and Web Server Module are required on the central server.

Open mSupply

- Open mSupply is the multi-platform mSupply software that has been under development by the mSupply Foundation since 2020. Open mSupply has all of the flexibility of all of the other versions of mSupply with the benefit of being Open source.

- Being Open Source software, mSupply Mobile has zero license fees. The Synchronisation server Module and Web Server Module are required on the central server.

Comparison table

The key differences between the configurations basically comes down to how the user(s) interact with the database. We hope this table helps in making that decision.

| Product / configuration | Description | Software price implications - refer Pricing |

|---|---|---|

| Free-user | PC or Mac application - Download here. The database resides on the computer that the application has been installed on. It can be used by only one user at any one time. | Free! You still need to register mSupply with Sustainable Solutions, but we don't charge you for it - and we don't sell your contact details either! |

| Single-user | Same as Free-user, but for users who wish to make use of Support3) and Up-to-Date (UTD)4) | A software license needs to be procured, generally for about 1/3 of the price of a multi-user client, and then Support and UTD on top of that. |

| Multi-user (Server / client) | For situations where more than one user needs to access the database at one time. The database is hosted on a file server and mSupply server software is installed on that hardware. Users have access to this data through mSupply client software installed on client PCs that communicate to the server through a Local Access Network (LAN). Remote users can access the server through Remote Desktop Protocol (RDP) or similar. | A software license needs to be procured for each concurrent client. Support and UTD is optional, but highly recommended. Most of our customers are very happy to pay for these services. |

| Synchronised Multi-user | If the internet connection to remote users in a Multi-user configuration is inadequate, then synchronisation allows a Primary - Satellite configuration to be deployed. 'Satellite' multi-user servers are installed at remote sites where users operate mSupply on their local store without worrying about the internet connection. In the background, these 'satellite' servers will synchronise their local store data with a 'Primary' server when the internet connection becomes adequate. | A software license needs to be procured for each concurrent client for each server. The Synchronisation server Module and Web Server Module are required on the central server. |

| Synchronised Single-user\\ (Single-user sync) | There are situations where the remote sites (with poor internet access) are just single-operator stores needing to manage and report their stock using the fully featured mSupply client. Procuring the minimum multi-user satellite server configuration for each of these sites would be expensive. A solution has been developed that entails installing single-user clients machines (normally laptops) at these remote locations and then synchronising them to the primary server much like the Synchronised Multi-user configuration. | Lower cost than conventional synchronised multi-user as the single-user client license is less costly than multi-user client licenses. The Synchronisation server Module and Web Server Module are required on the central server. |

| mSupply Mobile | mSupply Mobile is Open Source software that is similar to the synchronised Single-user configuration, but the users operates the software app on an Android tablets. This app has a reduced feature set, but is more than adequate for most Last-Mile needs. Local stock details are synchronised back to the Central server, and can be monitored and reported on there. | Pricing is even lower than for Synchronised Single-User. This was the way forward for the medical supply chain in small and remote facilities - until Open mSupply (see below) took that honour! The Synchronisation server Module and Web Server Module are required on the central server. |

| Open mSupply | Open mSupply is the Open Source software multi-platform mSupply software that has been under development by the mSupply Foundation since 2020. Open mSupply has all of the flexibility of all of the other versions of mSupply with the benefit of being Open source. Local stock details are synchronised back to the Central server, and can be monitored and reported on there. | Pricing for smaller facilities (single-user stores) is the same as mSupply Mobile. We see this as the way forward for the medical supply chain in both small and remote facilities and in large multi-user facilities. The Synchronisation server Module and Web Server Module are required on the central server. |

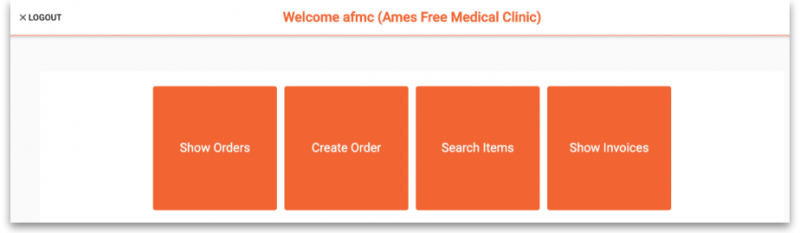

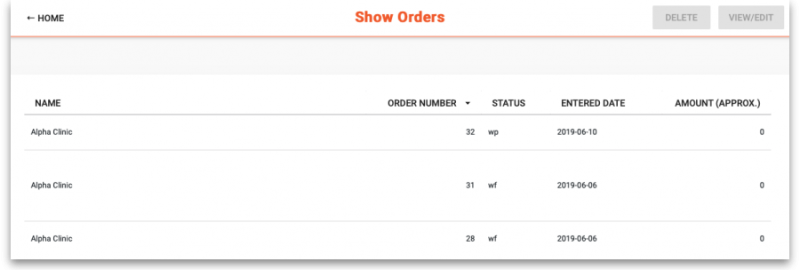

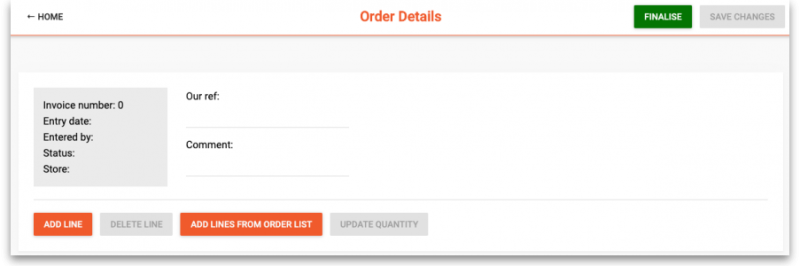

| mSupply Customer Web Interface | Allows staff of Customers in your mSupply system order stock on-line. It runs on a browser on any device: tablet, smartphone, net-book, desktop computer etc. It's a little hard to see why this should be chosen over Open mSupply, as the costs are very similar, without the benefit of being able to operate a store… | Depends on your situation - contact us. The Web Server Module is required on the central server. |

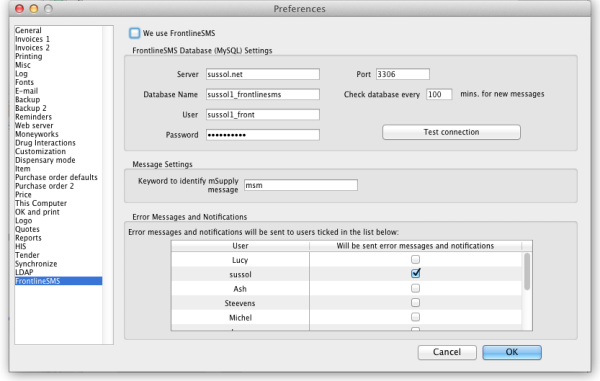

| FrontlineSMS integration | mSupply has the ability to integrate with a FrontlineSMS installation. This allows a customer to send their current stock levels to mSupply using an SMS (text) message from any mobile phone. This is particularly useful if, for example, you are a mobile or remote health post or dispensary which doesn't have internet access and only needs to send in information about a few items at a time. | SMS module is required on the central server. |

Other modules

Other modules are available for addition to the basic mSupply application:

| Module | Comments | Software price implications - refer Pricing |

|---|---|---|

| FrontlineSMS | Allows users to send their current stock levels to mSupply using an SMS (text) message from any mobile phone - even with only 2G reception!. This can then be used by mSupply to determine how much stock to send to the facility. | Equal to the price of 1 client license. |

| Product (drug) Registration | Allows integration of product registration (control of what products can be supplied by authorising particular suppliers and products) by recording and tracking the status of supplier's registrations and storing the documentation for easy retrieval. | Equal to the price of 2 client licenses. |

| Web Server Module | Allows you to access mSupply data on the server from any networked computer that has internet access. This module is a prerequisite for several other modules. | Equal to the price of 2 client licenses. |

| Synchronisation server Module | Maintains data integrity between a central mSupply server and 'satellite' mSupply servers. It therefore only applies to situations where there is a multi-mSupply server setup. Requires the Web Server. | Equal to the price of 2 client licenses. |

| Tender Management | Allows execution of a full tender process including publishing of the tender through a web site, and so allowing tenderers to submit tenders on-line. Requires the Web Server. | Equal to the price of 1 client license. |

A note about costs...

Software costs

When procuring software, an obvious question is what does it cost. We try to be as up-front as possible about what mSupply software costs. Even so, it's complicated. As you can see above, the mSupply ecosystem is complex and each component has different costs. For a start, we've tried to document the software costs on our pricing page. The amounts that you might pay for mSupply software can be divided into three components:

- License costs Thanks to the generous support of many donor agencies over the decades of mSupply's existence, only the mSupply products built on the (very good!) 4D database engine incur a license fee, up-front, lasting forever - refer Pricing. Not all of the 4D based mSupply products have a license fee; Free-user is … free

.

mSupply Mobile and Open mSupply are both Open Source software, and so are FREE of licence fees. - Installation costs mSupply systems need to be configured to the needs of the supply chain system. In principle, software and hardware configuration can be done by system administrators in the host organisation. However, in most cases, the mSupply Foundation is engaged to assist with software and hardware configuration. This is often done initially by one or more consultants travelling to the country for a number of weeks. The costs of this will normally be in the tens of thousands of dollars. Once a country has an mSupply system up and running, additional stores and sites can normally be added at much lower costs, with indicative prices below. For large implementations, local configuration capacity needs to be developed, and the mSupply Foundation is very keen to train local system administrative configuration capacity.

- Configure a store, not including storage locations and complex user profiles: USD 100

- Configure hardware:

- Tablet: USD 25

- Single-user PC: USD 100

- Server: USD 200

- Maintenance costs As with any technology systems, there are ongoing maintenance costs including keeping software up-to-date5) and providing support. This support could be provided by system administrators in the host organisation. However, in most cases, it has been found to be more effective to engage the mSupply Foundation to provide support, at least in part. For large implementations, local support capacity needs to be developed, and the mSupply Foundation is very keen to train local system administrative support capacity.

And all the other costs

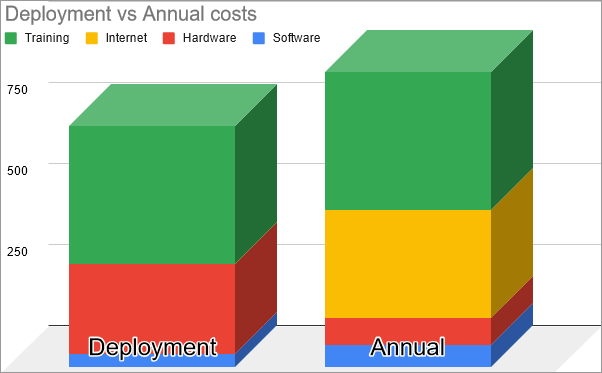

Software is never the largest component of deployment and operational costs. Local circumstances can vary dramatically, but in one a typical developing country with in excess of 500 mSuppy stores, the experience has been that after the expensive initial deployment, deployment and operational costs have been:

| Cost type | Deployment | Annual operation |

|---|---|---|

| License | 0% (Open source) | 0% (Open source) |

| Configuration / Support | 5.6% | 7.6% |

| Hardware | 37.3% | 9.1% |

| Internet | 0% | 36.6% |

| Training | 57.1% | 46.6% |

Note that in this particular country, the annual costs of a the cheapest commercially available cellular internet connection exceeded the capital cost of the 10“ Android tablets.

Key conclusions:

- Training is the highest cost (rightly so!)

- Provision should be made for hardware depreciation (devices do break, get stolen, etc.)

- Software costs are normally < 10% of the costs (capital and operational)

Referring to the server machine vs. server software

We need two servers!!!???

The ICT industry is plagued by the practice of using the same term to refer to software, hardware or both combined! As it relates to mSupply in multi-user environments, there is often confusion over two of these:

- The term 'Server' can refer to:

- The mSupply server computer software which runs the mSupply database,

- The hardware which the mSupply server software is installed on, and;

- Both the hardware and the software acting together. This is possibly the most common usage. When we say something like “send to the server” we mean send data to the server software operating on the server hardware.

The server hardware can actually be a cloud hosted 'service' rather than physical hardware that you own and try to manage. Sometimes the server hardware is referred to as a 'file server', and this can help to avoid confusion. In any case, for any multi-user mSupply installation, including mSupply mobile, both server software and server hardware are needed, and both of them cost money.

- Similarly, the term 'Client' can refer to:

- The mSupply client computer software which accesses the mSupply server (software) database on the server (hardware),

- The hardware which this client software operates on, and;

- Both the hardware and the software acting together.

Sometimes the client hardware is referred to as a 'client PC' (Mac or Windows) and this can help to avoid confusion. Again, for any multi-user mSupply installation, including mSupply mobile, both client software and client hardware are needed. For mSupply mobile, the client hardware is an Android Tablet - refer Mobile (Android) user guide v2.0 - featuring offline operation.

We are a software company, so when we use these terms, we will almost certainly be referring to our software, but sometimes not. The context normally helps, but please forgive us if we fail to distinguish between these meanings!

1.03. Who uses mSupply?

This list isn't exhaustive.

All sites are multi-user with the number of sites x number of concurrent users at each site in brackets unless denoted by SU (=“Single User”) after the name.

Our 3 largest users are:

| Country | Total Sites | Desktop Sites | Mobile Sites |

|---|---|---|---|

| Myanmar | 900 | 900 | 0 |

| Côte d'Ivoire | 1996 | 1200 | 796 |

| Papua New Guinea | 447 | 42 | 405 |

Open mSupply installations are in:

- Djibouti

- Timor-Leste

- Mali

- Sao Tome

- with Côte d'Ivoire, Niger, Chad, Republic of Congo all planned for 2025

Africa (16 countries)

Angola

- Went live at CECOMA (their CMS) in September 2023)

Côte d'Ivoire

- Designated national system

- Type of system: WMS & ELMIS

- As of December 2021: over 700 sites- mixture of desktop and mobile

- 30 sites with World Bank funding from 2021

Djibouti

- Went live at 14 sites May 2023

Democratic Republic of Congo

- Cordaid (3)

Gambia

- Gambia Central Medical Stores (14)

Ghana

- Central Medical Stores (5)

- Status 2015: CMS was destroyed in a fire in 2014, and the project has been on hold since then.

Niger

- 2 regional warehouses managed by Chemonics (SU) - 2020

Nigeria

- Six Government state stores (6 x 3)

- Ten Government stores managed by Axios (10 x 2)

- Axios HQ, Abuja (4)

- Axios uses mSupply synchronisation to connect sites that don't have full time internet access. This system has been in use since 2010, and continues to function well.

- FCMS Store, Lagos (5)

- Jigawa CMS

- From March 2016: 20 new users spread over 6 states (Kaduna, Katsina, Zamfara, Kano, Jigawa, Yobe)

- Private non-pharmaceutical supplier, Lagos (STIL)(SU)

- UNFPA warehouse, Lagos (5 users) - 2021

Liberia

- Axios: 1 site synchronising to a central server

- Liberia MoH: 11 sites being consolidated to a single mSupply installation Dec 2016

- using EPI module: yes

Malawi

- Orant Charities (SU). From 2017.

- Nkhoma Hospital Pharmacy Department. From 2015

Mali

- UNFPA Open mSupply pilot, December 2024 onwards

Sāo Tomé and Principe

- Designated national system

- Type of system: WMS & ELMIS

- National supply chain system (10 users 2021, expanding to 40 users in 2022)

Sierra Leone

- Designated national system

- Type of system: WMS & ELMIS

- MRC (SU)

- Crown Agents Ebola Response and Free Health care distribution (20) - several stores around Freetown running from a single cloud server.

- National Pharmaceutical procurement unit (2017). Central server with 18 users, 13 regional sites, et al.

- LSHTM Ebovac (2017). Server with 5 users.

South Sudan

- Designated national system

- Type of system: WMS & ELMIS (expanding to ELMIS H2 2022)

- MoH Central Medical Stores (5 users)

- Expanding to whole country in 2022

- UNDP Juba (5 users)

Zambia

- Churches Health Association (4 users)

Zanzibar

- ZILS (5 users)

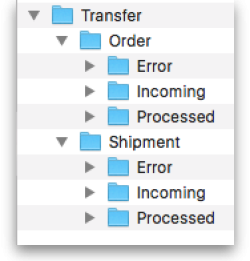

- this system employs an EDI interface to pick up orders sent to a dropbox folder from the Zanzibar LMIS system and incorporates it into mSupply

- expanding to Pemba in 2022

Pacific (15 countries)

Cook Islands

- Desktop Sites (5) - 2018

- Mobile Sites (10) - 2018

- using EPI module: yes

Federated States of Micronesia (FSM)

- 7 users at CMS/main hospital - 2012

Kingdom of Tonga

- Central Pharmacy Medical Stores (3)

- Vaiola Hospital (4)

- Haapai Hospital (SU)

- Vava'u Hosptial (SU)

- 'Eua Hospital (SU)

- Mobile (11)

- National Covid 19 vaccination program run using mSupply mobile - 2021

- using EPI module: yes

Kiribati

- Designated national system

- Type of system: WMS & ELMIS & Covid Vaccination Record

- Tungaru Hospital (9)

334 sites using mSupply mobile- National Covid 19 vaccination program run using mSupply mobile

- using EPI module: yes

Marshall Islands

- Ministry of Health/Majuro Hospital (2)

Nauru

- Central Hospital and Stores (6 users)

Palau

- 3 sites including CMS- went live in 2022.

Papua New Guinea

National Department of Health

- Designated national system

- Type of system: WMS & ELMIS

- Central server (cloud hosted) with 12 client users

- 28 Sync server sites (Area medical stores (AMS), provincial hospitals) with 118 client users

- 13 Single-User desktop sync sites (district hospitals)

- 105 Mobile sites (Health centres)

- 300 Mobile sites (UNICEF) 2022

- using EPI module: yes

Burnett Institute

- 8 mobile sites (Strive project)

Solomon Islands

- Designated national system

- Type of system: WMS & ELMIS

- National Medical Stores (14 users + Web server + Tender module)

- National Referral Hospital (4)

- mSupply mobile- 50 Second Level Medical Stores (phased installation from October 2016)

Tokelau

- 3 sites covering country - 2018

Tuvalu

- Princess Margaret Hospital (2)

Vanuatu

- Designated national system

- Type of system: WMS & ELMIS

- Central Medical Stores (2)

- Vila Central Hospital Pharmacy and Store (3)

- Lenekel Hospital (2)

- Norsup Hospital (2)

- Luganville Hospital (2)

- using EPI module: yes

Fiji

- Designated national system

- Type of system: WMS & ELMIS

- National deployment to 230 sites started October 2020.

- Aspen Hospitals x 2

Samoa

- Nationwide deployment (approx 18 sites) started July 2020 - completed 2022

- Using mSupply Coldchain for monitoring fridges, including receiving Telegram alerts for breaches.

Niue

- Using mSupply for pharmacy store and all dispensing.

- Using mSupply Coldchain for monitoring fridges

Asia (3 countries)

India

- Meyer Free Clinic

Nepal

- INF (3 sites- SU)

- MSMT (SU)

- Patan Hospital (SU)

- Lal Gadh Hospital

- Gurkha Welfare scheme (26 sites, SU) Funders: DFID, GWT

Afghanistan

- Six NGOs responsible for medicine distribution in provinces synchronise data back to a management server in Kabul (July 2016). Includes automated generation of a multi-workbook Excel spreadsheet that includes macros that submit data to a Ministry of Health database.

- UNDP warehouse (2019- 5 users)

- CMS warehouse (2019- 5 users)

- AFIAT project: 70 sites

- UNCEF : starting to roll out as national system from May 2025

South-East Asia (4 countries)

Cambodia

- World Mate Emergency Hospital

- WMEH Warehouse

Laos

- Designated national system

- Type of system: WMS & ELMIS

- 186 sites (complete Nation implementation) using mSupply synchronisation

Myanmar

- Designated national system

- Type of system: WMS & ELMIS

31, no42150362639 sites using synchronisation to connect to a cloud server, with plans to extend to 3000 sites over the next few years.- Medical Action Myanmar (Dec 2017) - 25 mobile sites connecting to a cloud server running mSupply.

- UNICEF funded EPI program - approx 350 sites starting 2021

- using EPI module: yes

- Zenith TRI (2022 onwards): another ~40 sites on a separate system serving NGOs

Timor-Leste

Ministry of Health

- Designated national system

- Type of system: WMS & ELMIS

- Sites

- SAMES (10)

- Hospital Nacionale Guido Valedares (5)

- Dili Central Medical Services (Mobile)

- 100 mSupply mobile sites (expanding to over 300 in 2022)

- National Laboratory, Dili & 5 regional laboaratory sites

Menzies Health

- Central laboratory

- 8 remote laboratory sites

Americas (3 countries)

Colombia

- Bogota warehouse supported by Chemonics (2022)

- Valle del Cauca regional warehouse

- Cundinamarca regional warehouse

Haiti

- National warehouse run by Chemonics (2021)

- National Logistics System (2023/24)

USA

- SafeNetRx (was Iowa Prescription drug corporation)

- users: 2

- Web server: clients from all over Iowa place orders using the mSupply web interface

- SafeNetRx are the largest non-governmental supplier of free medicines in the USA.

Europe and the United Kingdom (1 country)

United Kingdom

- UK Microbiological Products supplier (Private company). Since 2012

- UK Med, suppliers of the UK-EMT (Emergency Medical team), responsible for the UK's international emergency medical response.

1.02. Why mSupply?

This section outlines the approach and ethos of Sustainable Solutions as well as the main areas of functionality that mSupply covers.

People

- Our aim is to serve developing countries with solutions that provide real benefit.

- We are driven by a desire to serve, rather than by profit.

- That said, we are a profitable company with no debt and a commitment to stay in business for as long as we are needed.

- We have a balanced mix of expatriate and Nepali staff who work on mSupply.

Experience

- We've been working on mSupply since 1998, and full-time as Sustainable Solutions since 2001. In that time we've done hundreds of days of training, converted hundreds of thousands of records from other systems to mSupply, and installed mSupply in hundreds of locations.

- Our experience in Nepal, and in many other developing countries, gives us a unique perspective and understanding of the challenges and opportunities involved in working in similar environments.

- We know that a decision to install mSupply is a big one. We're committed for the long term. We're planning to be here decades from now.

Ease-of-use

- mSupply is very easy to install- 10 minutes and a whole department is up and running.

- mSupply uses an easy-to-use graphical interface that makes it a breeze to add purchase orders, patient prescriptions, tenders, etc.

- The system is also made with high-usage warehouses and busy pharmacy departments in mind. he system automates item purchases, receipts and sales for the warehouse administrator, and also provides features such as abbreviated directions entry for quick prescribing of medicines.

- There is always a balance between features and usability. While we know we don’t always get it right, we try to make sure we don’t add features that aren’t really needed. Also, we make sure that features only needed by one client don’t clutter up the interface for everyone.

Stability and reliability

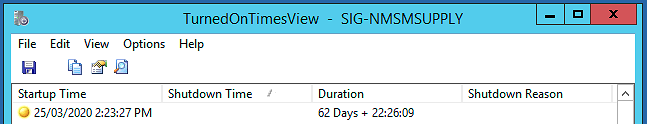

- The initial mSupply server installations in 2002 have run since then without ever crashing.

- We have more than ten years of experience in keeping mSupply installations running in developing countries, so we know what it takes to make a reliable system. All multi-user mSupply systems we have installed are still running.

- mSupply includes an automated internet backup system, so backups are automatically transferred to a remote secure site.

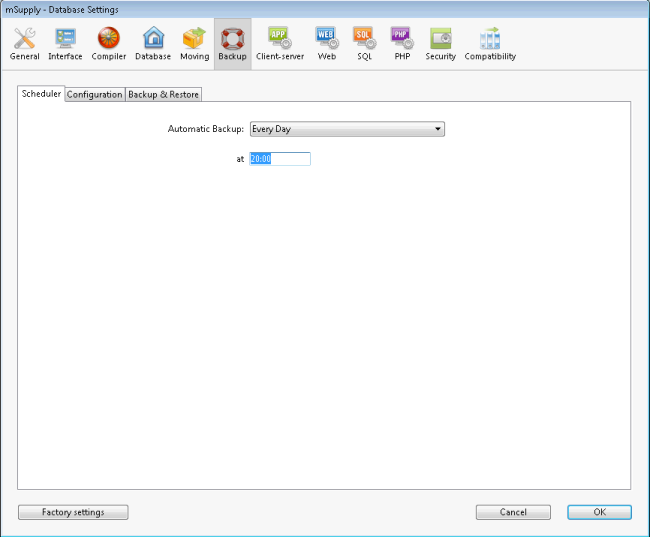

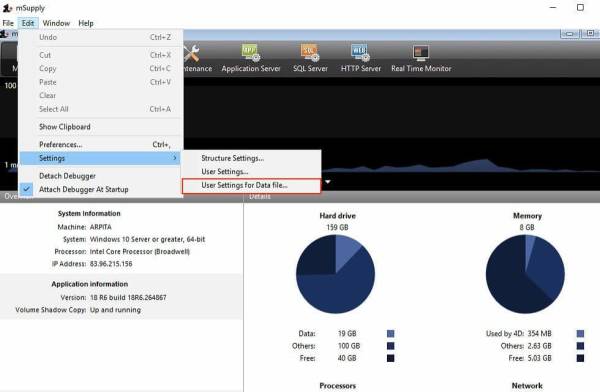

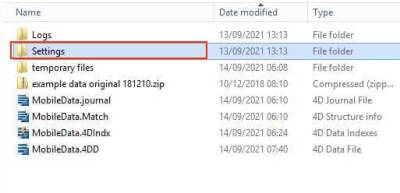

- Server backups are automatic with configurable frequency.

- mSupply keeps a log of every action you make, and if there is a power failure then the log can be used to restore all unsaved data on the server.

Security

- We do not know of any instances of a security breach of an mSupply server

- There is a full password protected login and permissions system, allowing each user’s access to functions to be controlled and recorded.

- A user log records all significant user interactions, allowing an audit of which user performed which actions.

Local or Cloud or both!

- mSupply can run in many different ways, depending on whether you want to run a local or cloud-based service:

- Local server with client connecting over your local network

- Cloud based server with clients connecting via a special application or a web browser (e.g. Citrix)

- If you have several sites and want to manage them centrally, but the internet does not support a cloud-based service, then mSupply also supports running individual servers at mulitple locations that then synchronise their data back to a central server when communications are available.

mSupply mobile

- On Sept 2nd 2013 we officially released mSupply mobile. It allows you to run a small medical store using a tablet computer (iPad or Android or Windows). An internet connection is required, but users in developing countries are successfully using mSupply mobile over an EDGE (2g) mobile network.

As of mid 2016, the internet connection does not need to be there all the time! See Mobile (Android) user guide

- mSupply mobile can give stock visibility and automated replenishment for hundreds or thousands of stores connected to a single server, which may be hosted on your premises or be cloud-based.

Scalable

- The same data file can grow from being used in a single-user system to having hundreds of concurrent users with millions of transactions.

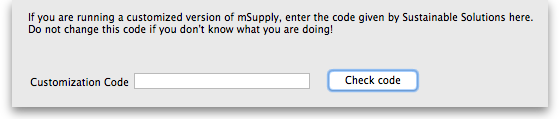

Customisation

- Many mSupply users have unique needs requiring some customisation of the standard mSupply software. mSupply allows customised versions that can still be easily upgraded as new releases are made. Often customisation is done at no extra cost if the client has a current up-to-date contract.

Specially designed for pharmaceuticals

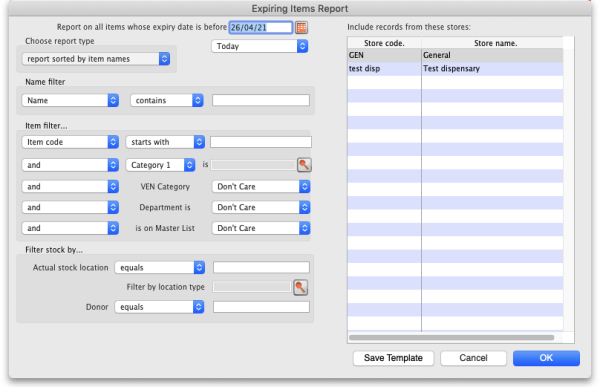

- mSupply is built from the ground up to handle batches and expiry dates.

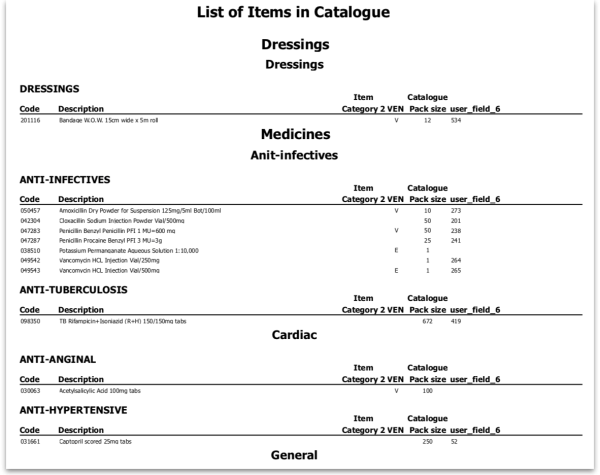

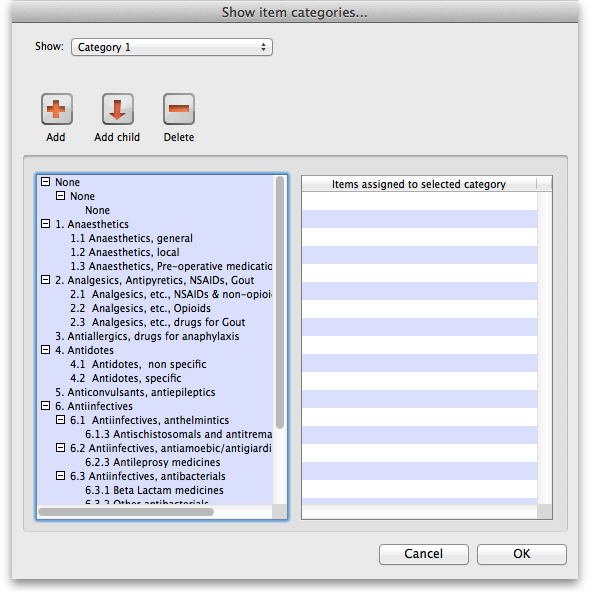

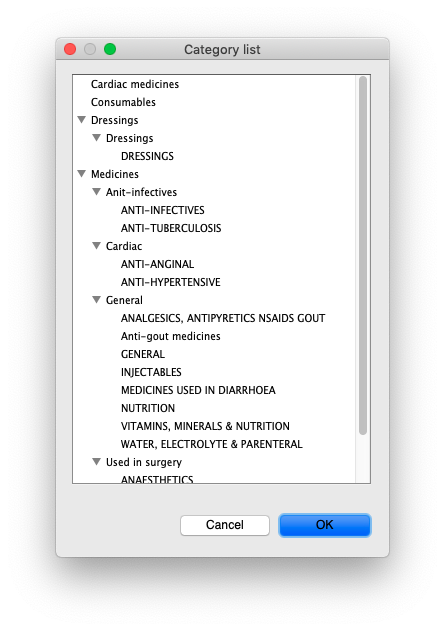

- There are multiple ways of classifying medicines, and mSupply supports ATC coding, WHO’s EDL6) categories and the user’s own custom categories.

- Many of the reports are specific to the needs of pharmaceutical distribution

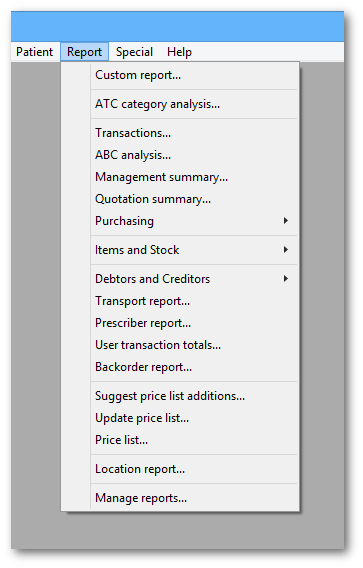

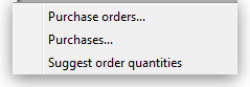

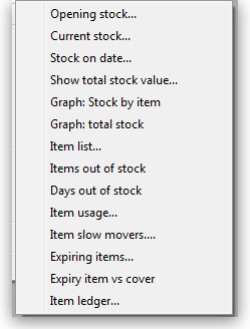

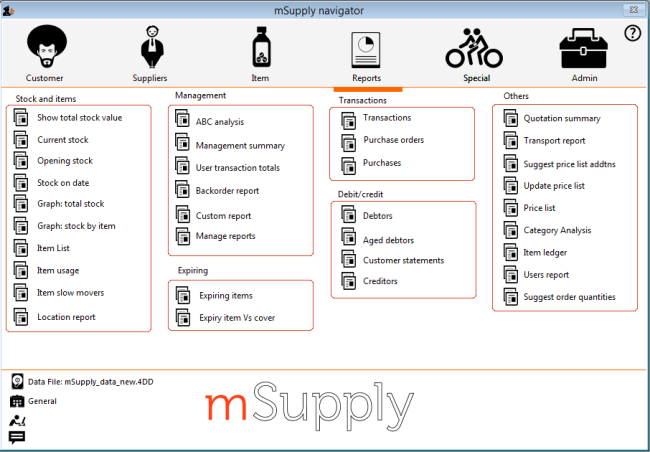

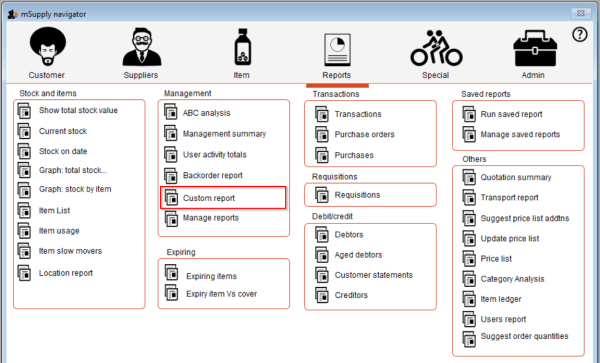

Reporting

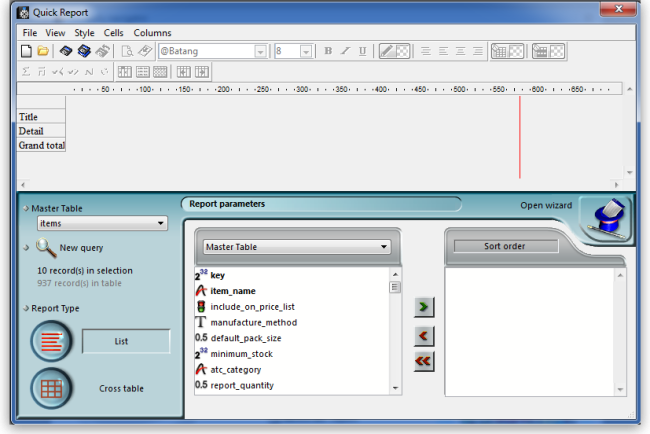

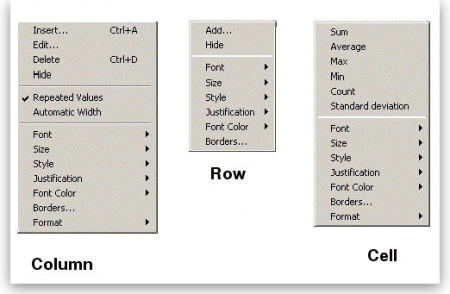

- The in-built reports have been developed since the beginning in response to user requests.

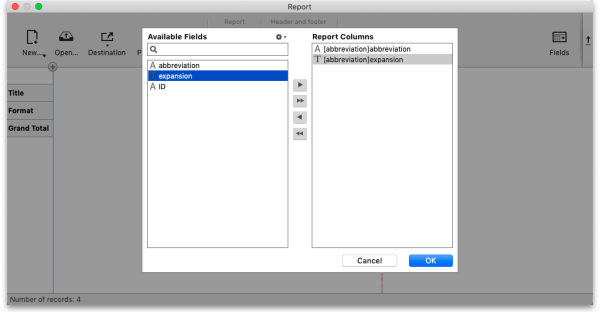

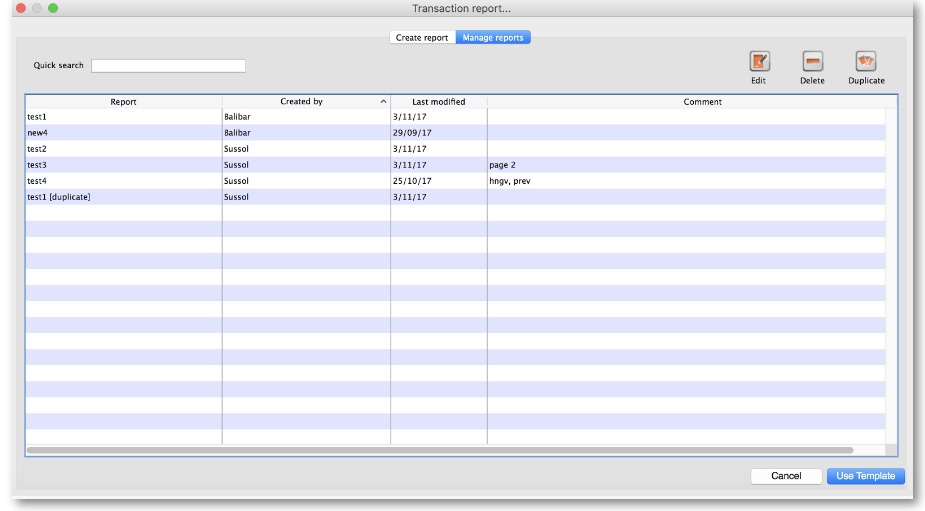

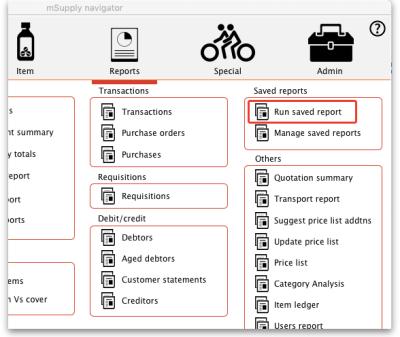

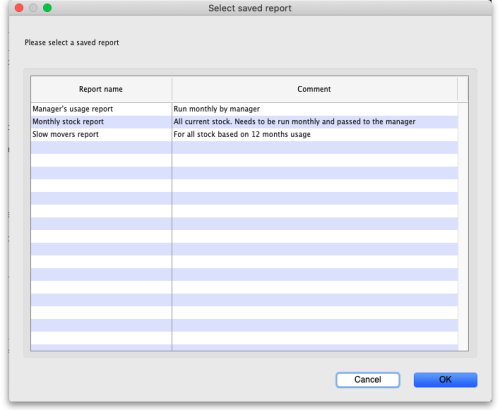

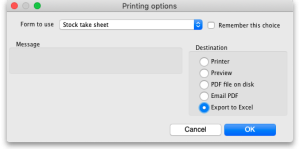

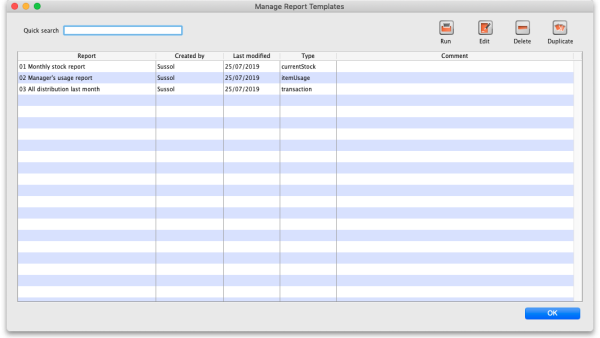

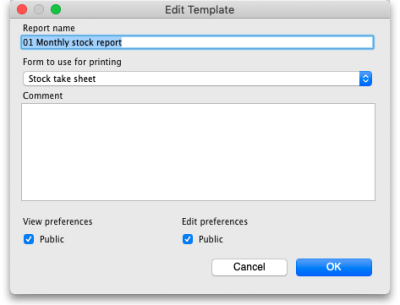

- Users can easily create their own custom reports and save them for use again. Saved reports are available from a menu in the custom report window.

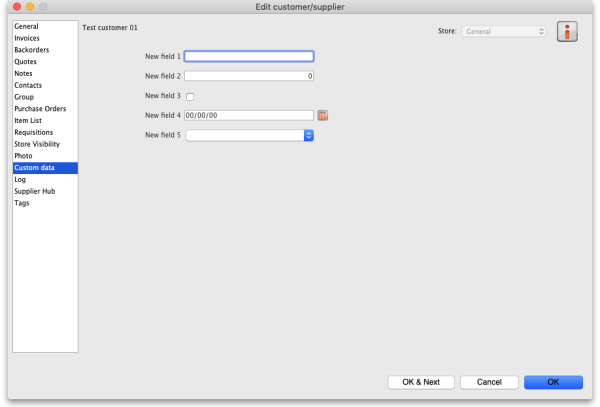

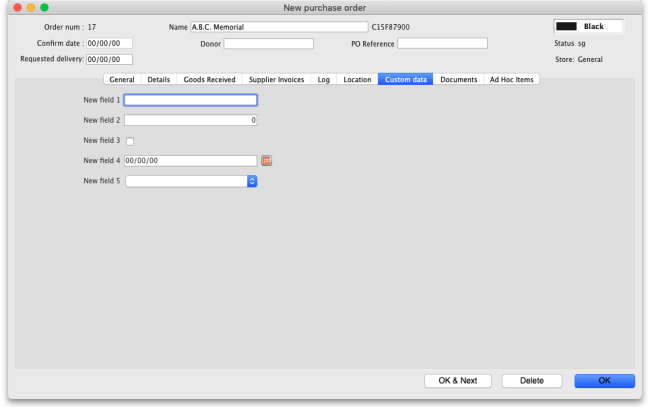

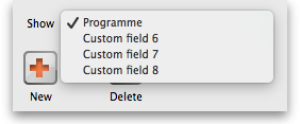

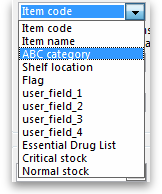

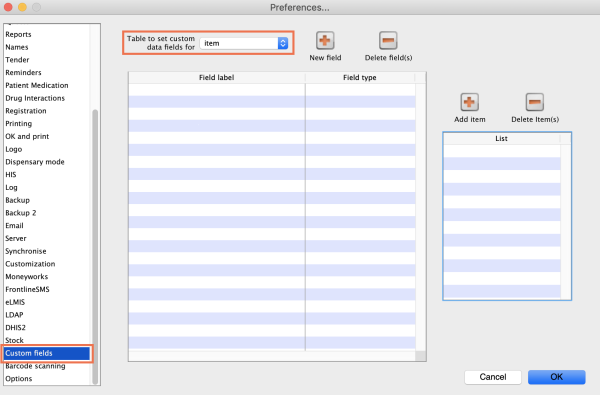

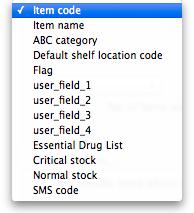

- Items, Names, and transactions all have lots of spare fields that users can use to store custom data, and then use those fields in reports.

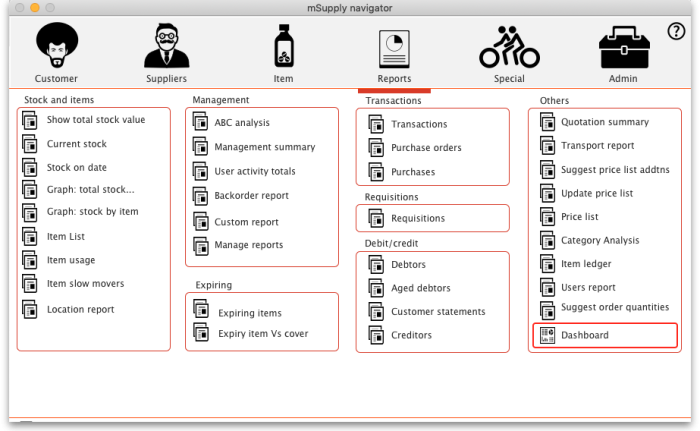

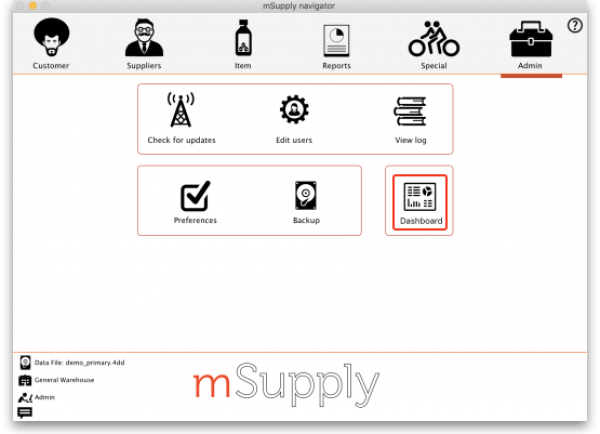

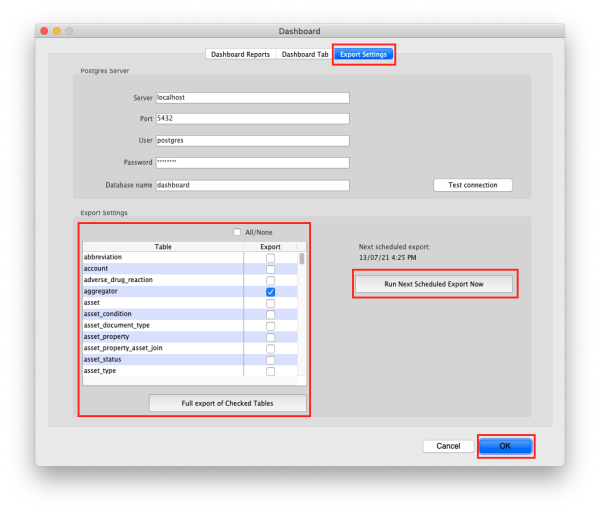

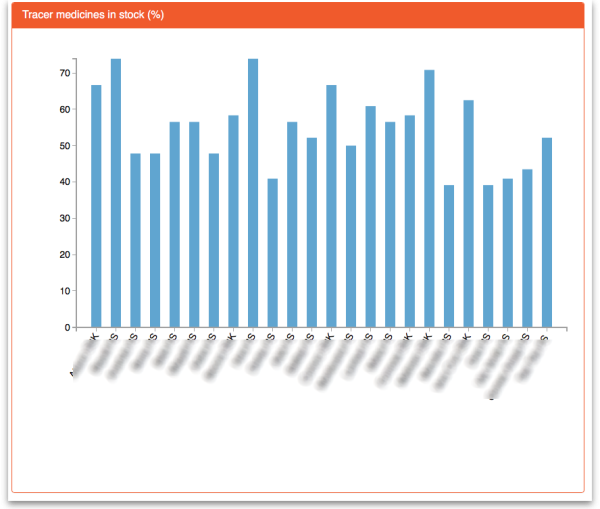

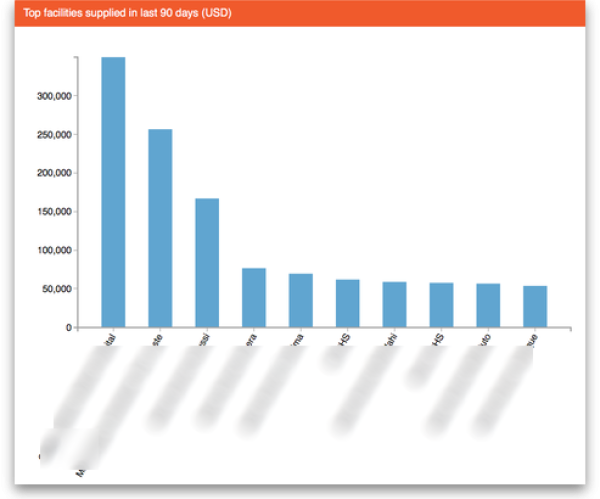

- mSupply dashboard allows managers in remote locations to log on with a web browser and view reports.

Mistake tolerance

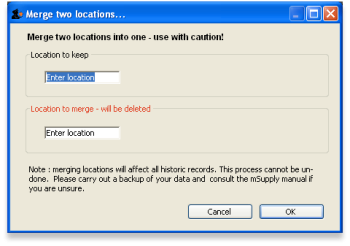

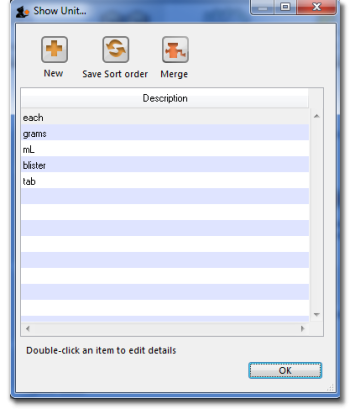

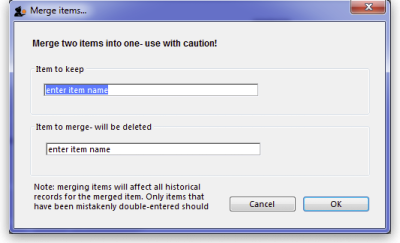

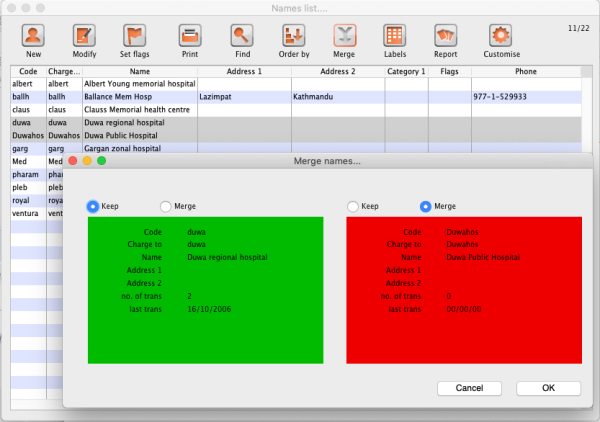

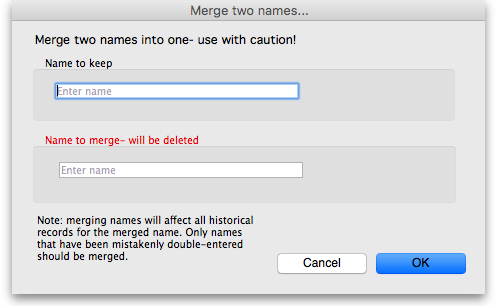

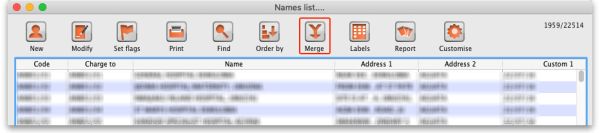

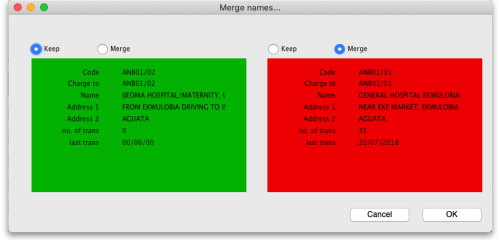

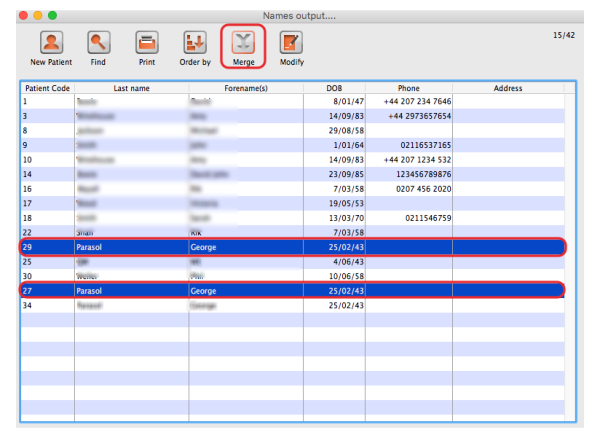

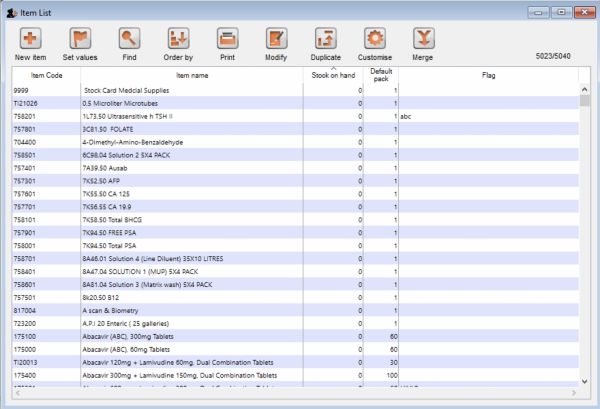

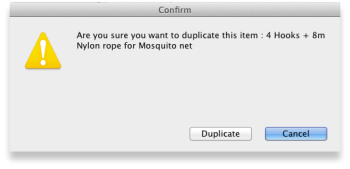

- mSupply provides easy merging of duplicate items.

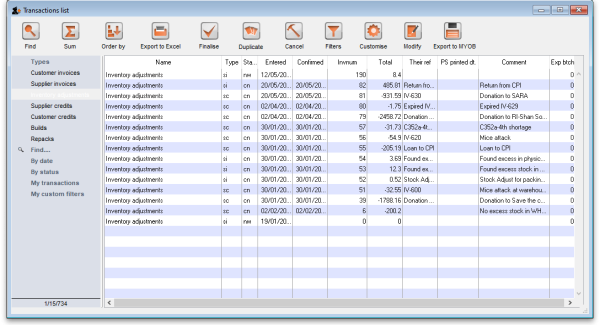

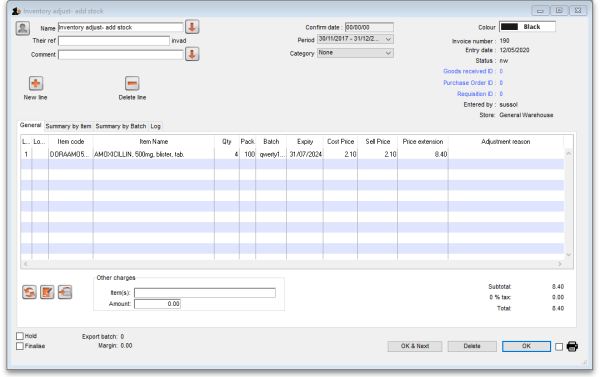

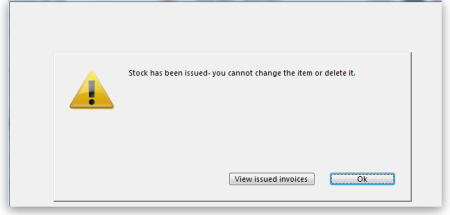

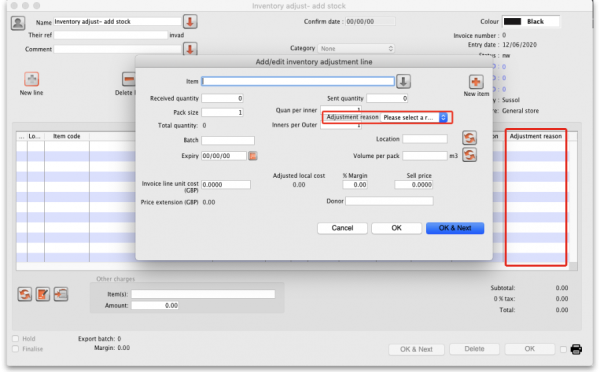

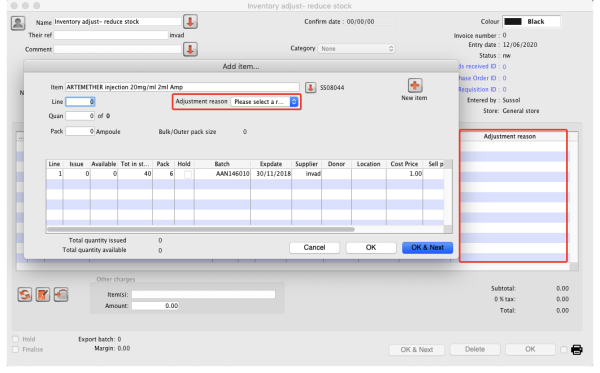

- Easy adjustment of inventory errors (but with a full audit trail!)

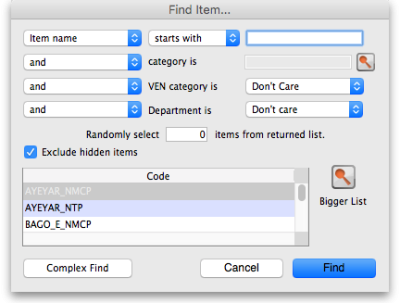

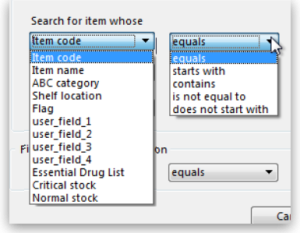

- Most fields allow entry by name or code, and allow partial entry of as much of the name or code as the user knows.

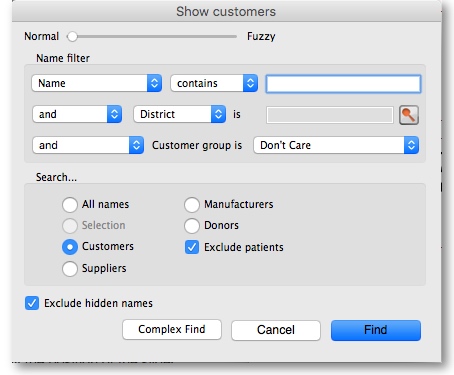

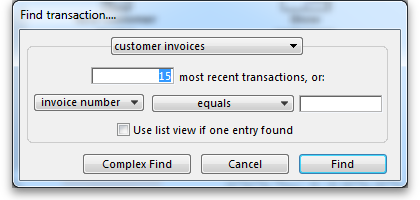

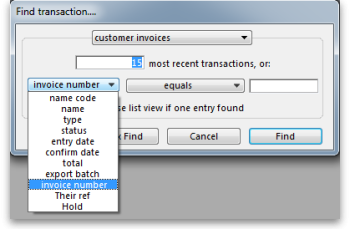

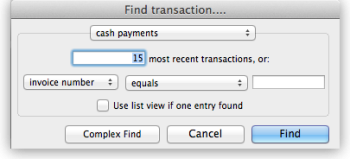

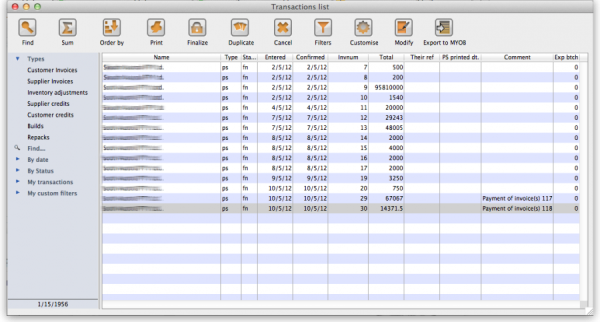

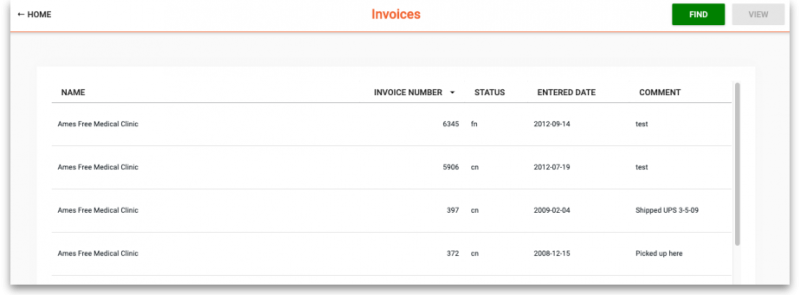

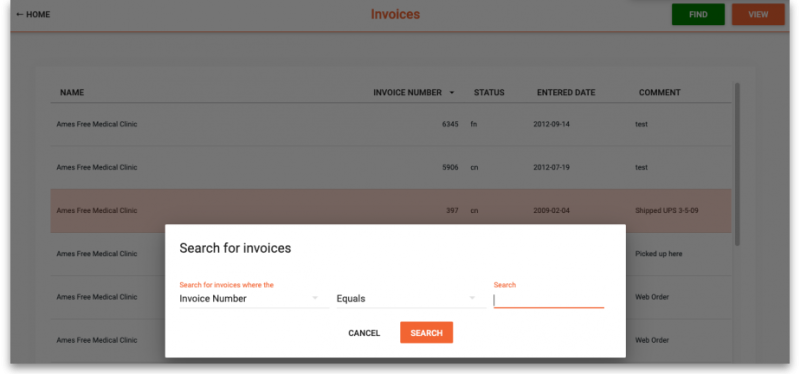

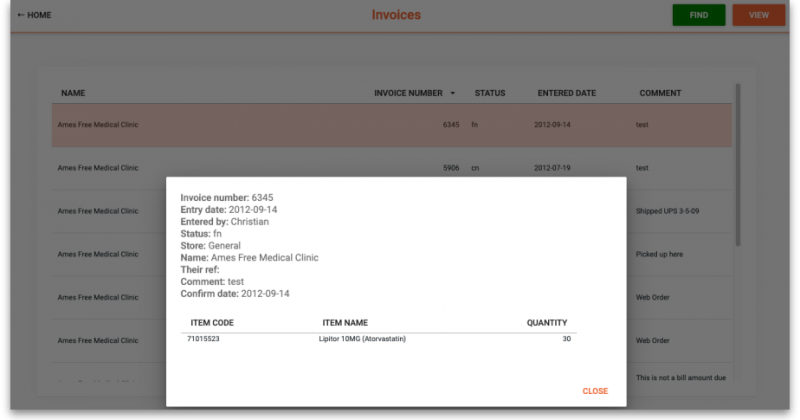

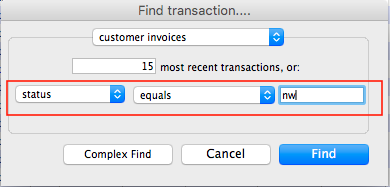

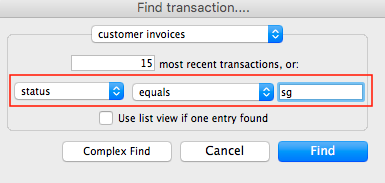

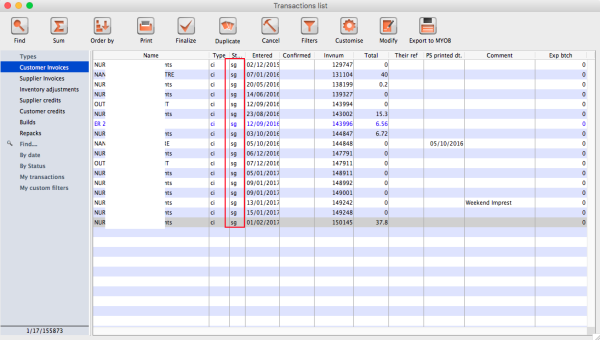

- Easily find transactions you've entered, by number, by customer/supplier name, by a list of recent transactions or by a custom search.

- If the user’s hardware is powerful enough, fuzzy find searches allow finding data even if the search terms are incorrectly entered.

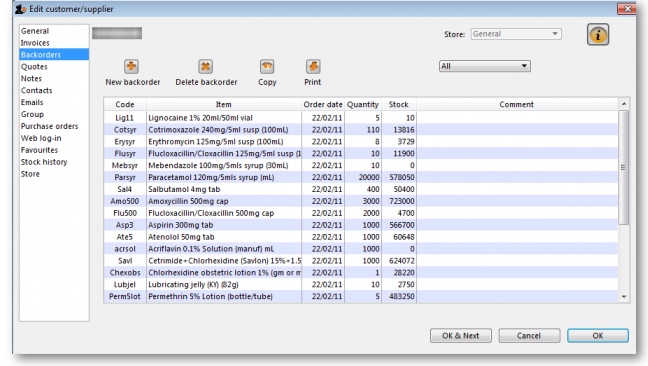

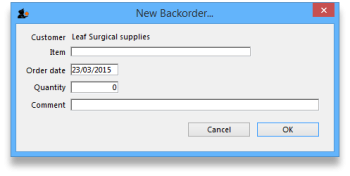

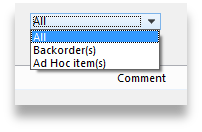

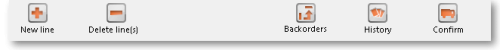

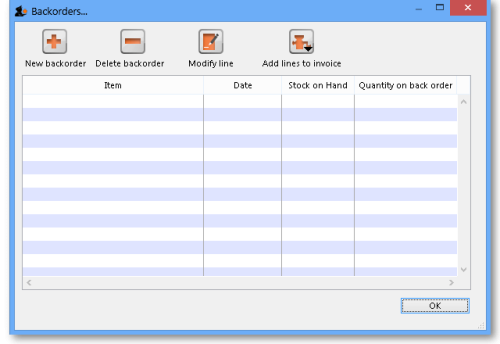

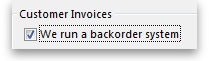

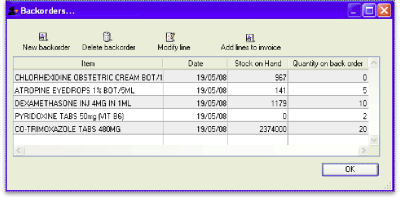

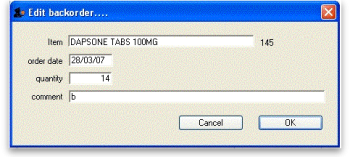

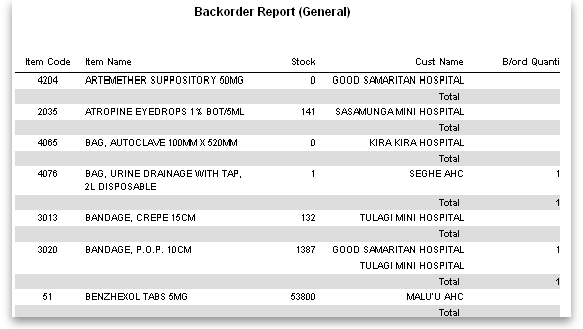

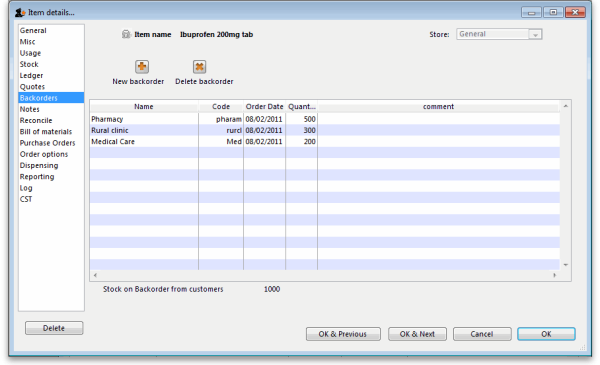

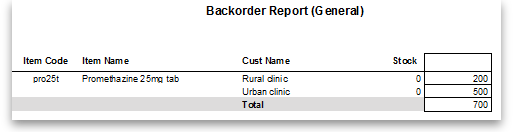

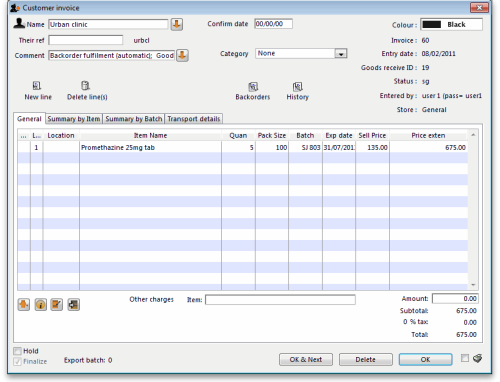

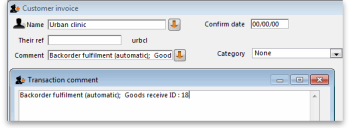

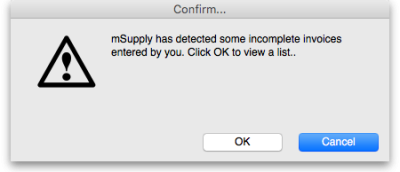

Backorders

- Items that you are unable to supply to customers are put onto backorder. A report of all backordered items is easily generated. When the stock for the backorder becomes available a customer invoice is automatically created awaiting your confirmation.

Web interface for customers

- mSupply allows customers to remotely log in via a web browser and place orders, view order status, stock status and transaction history. This system is in daily use.

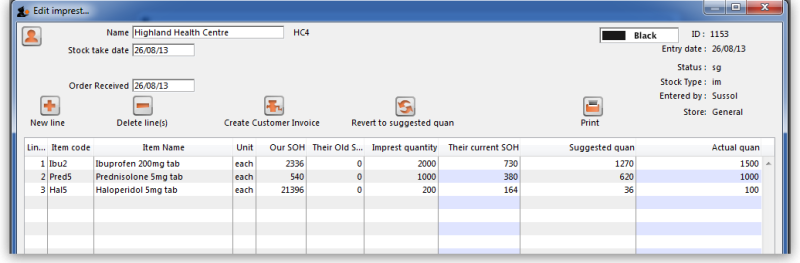

Customer stock history / indent ordering

- mSupply supports a unique system of centralised supply where the distribution point submits current stock on hand figures, and mSupply calculate a rational quantity to supply, knowing the historic stock on hand, the ordering cycle, and the amount supplied during the previous cycle.

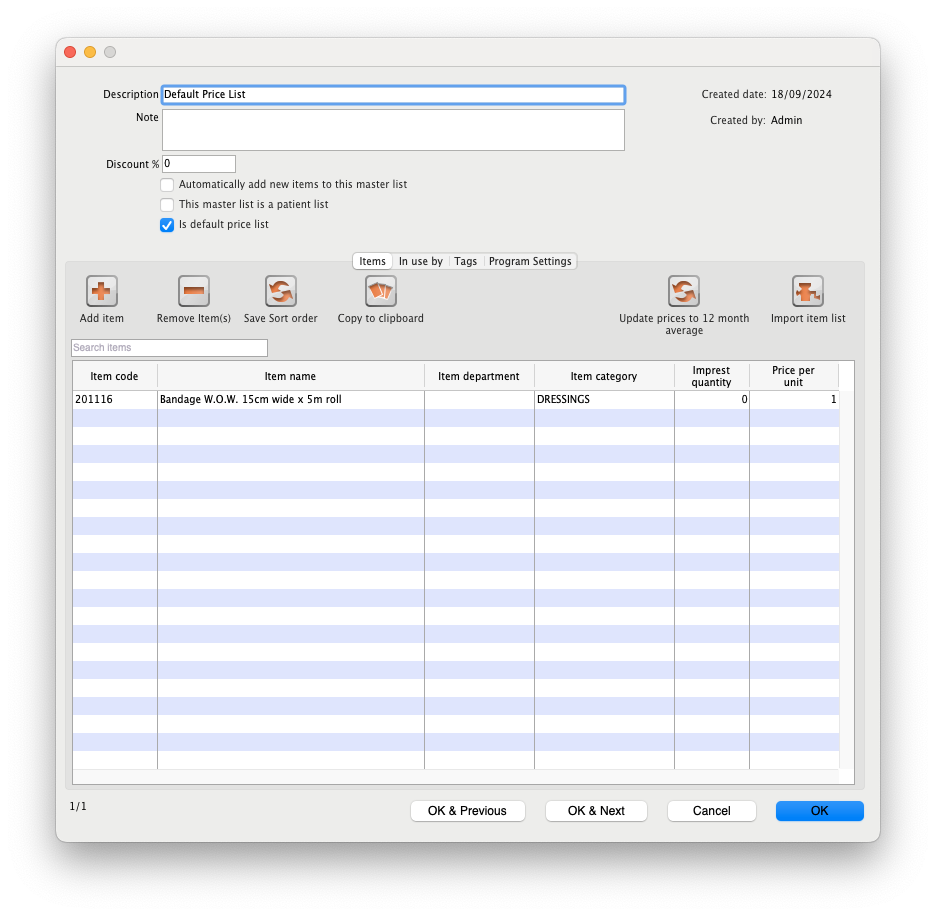

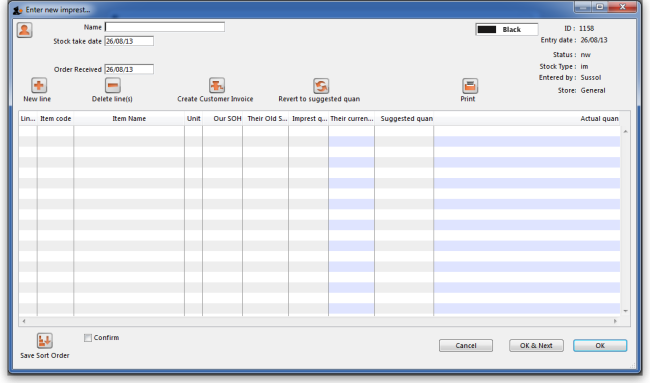

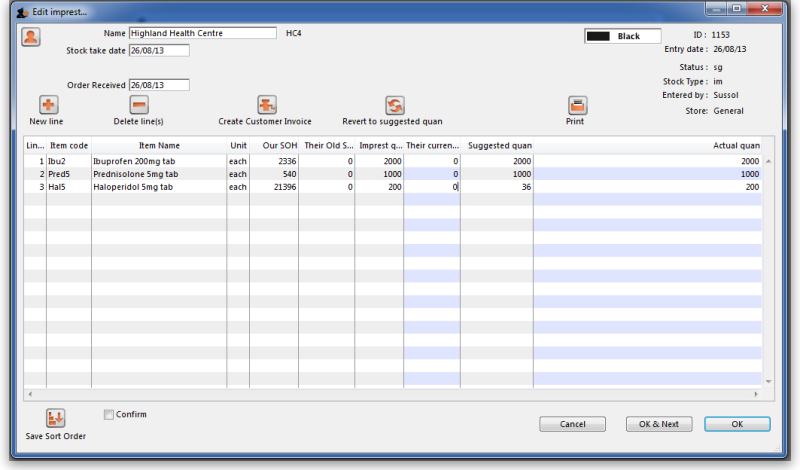

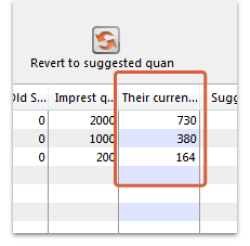

- mSupply also supports the simpler imprest system where the amount given to customers is based on a fixed level of stock, as is commonly done when supplying wards in hospitals.

Quantification

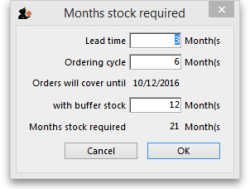

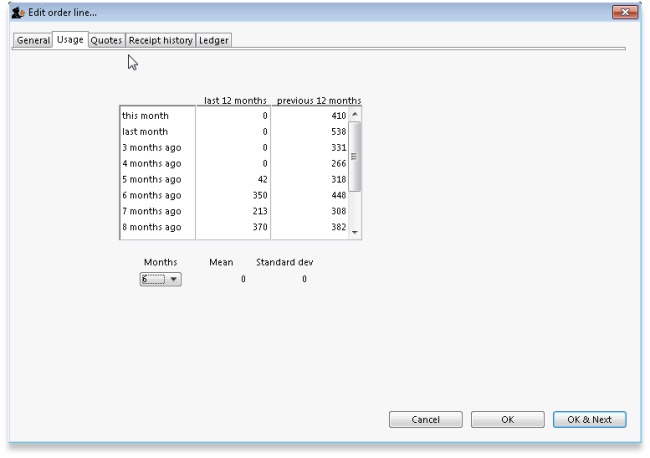

- mSupply uses a powerful ordering system that allows accurate real-time analysis of how much stock should be ordered, based on historic consumption, order lead time, the ordering frequency, desired “buffer” stock levels and current stock levels. Unmet demand from customers, backorders, and stock on order are also taken into account.

- This system has proven reliable, and requires little user intervention, unlike systems that require you to set minimum and maximum stock levels. mSupply still allows minimum stock to be set if really needed.

Procurement

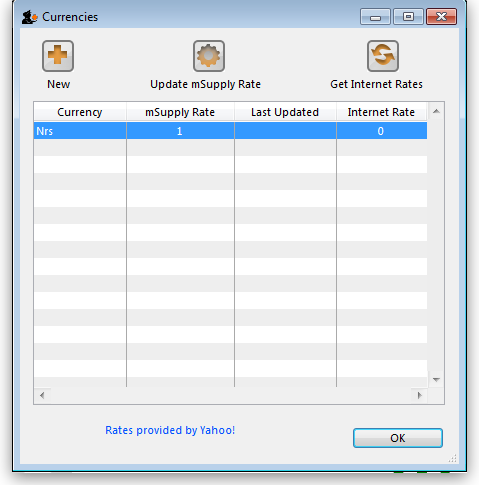

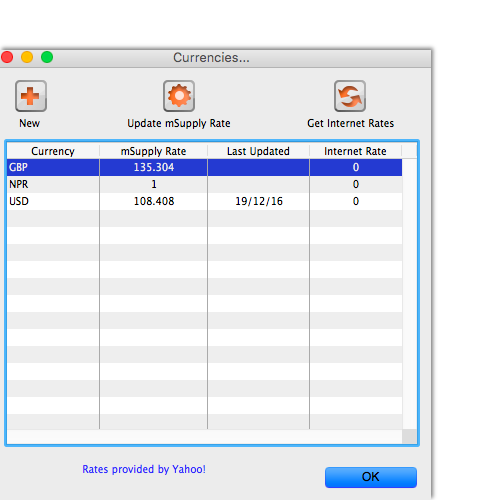

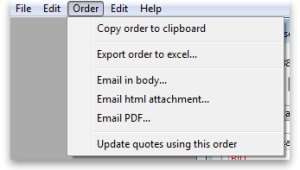

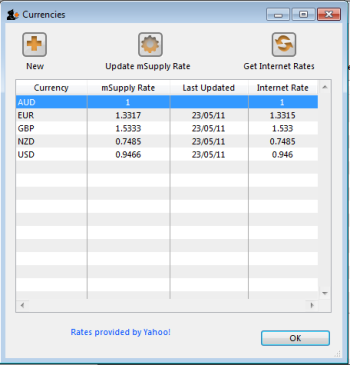

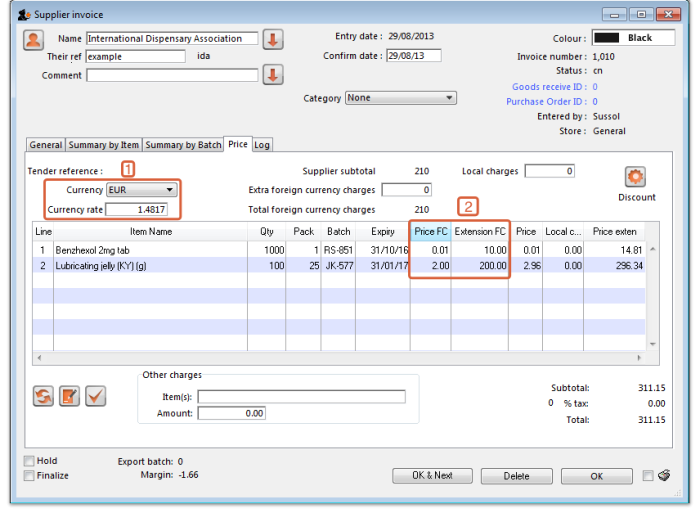

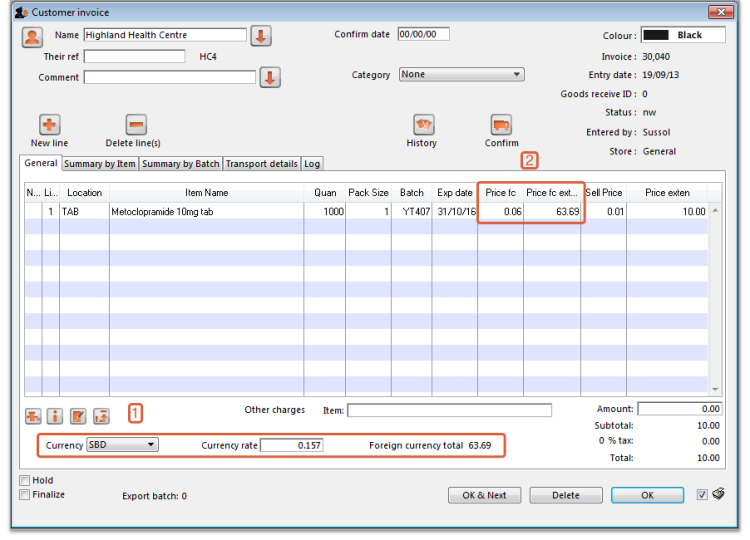

- mSupply handles purchase orders in multiple currencies, and allows split deliveries.

- The goods receipt module allows full or partial receipt of each purchase order plus addition of stock not ordered.

- Ad hoc quotes from suppliers can also be handled.

- The quantification, tender management and purchase order systems all tie together so data flows from one to the other without requiring re-entry.

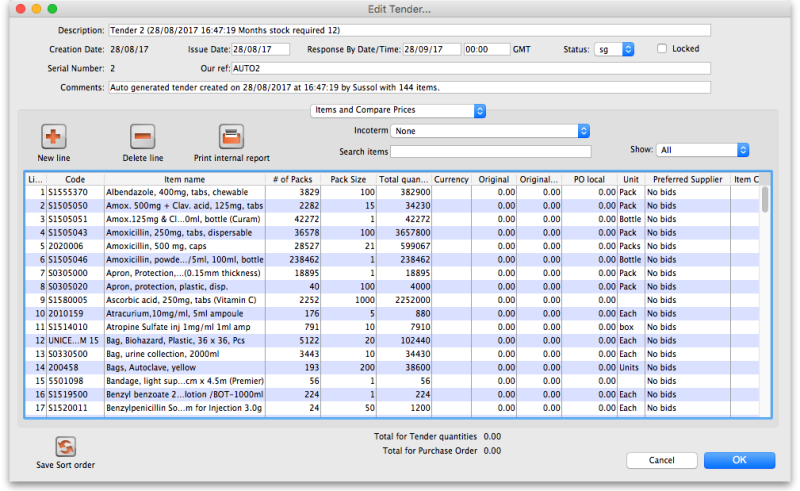

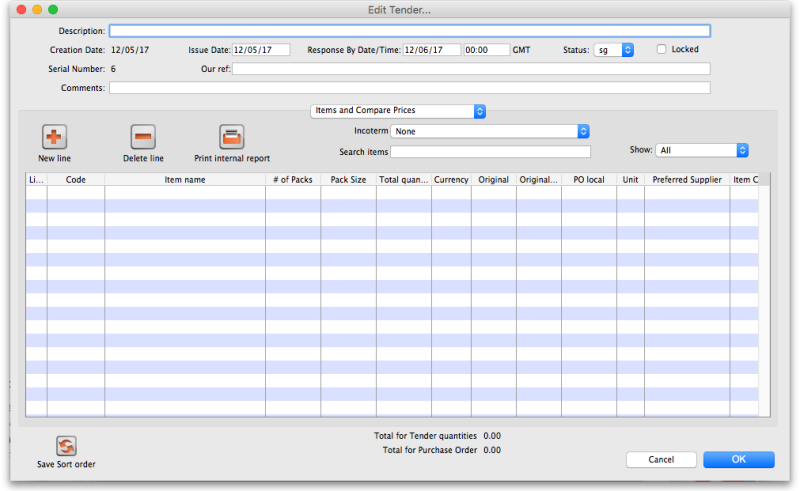

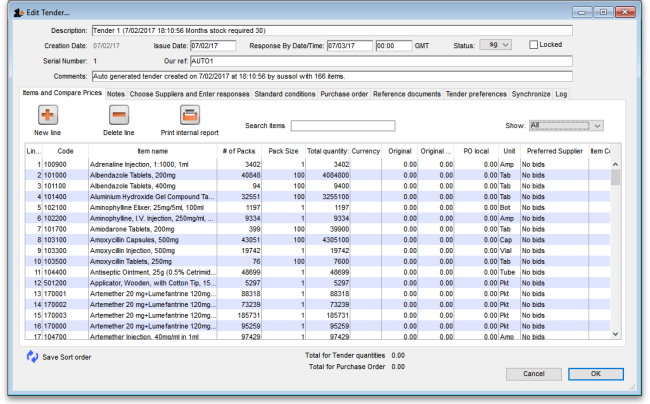

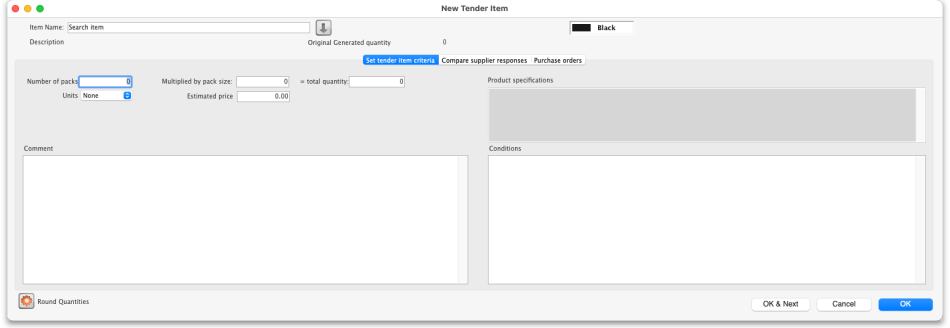

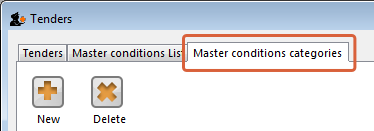

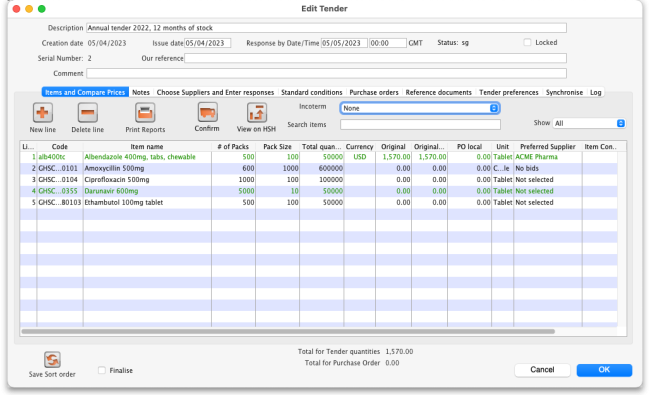

Tender management

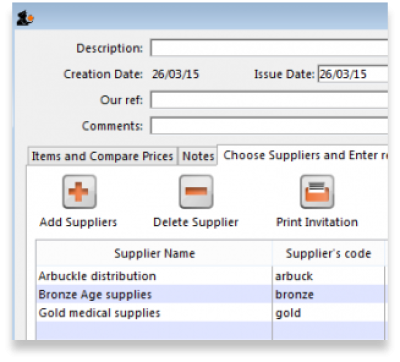

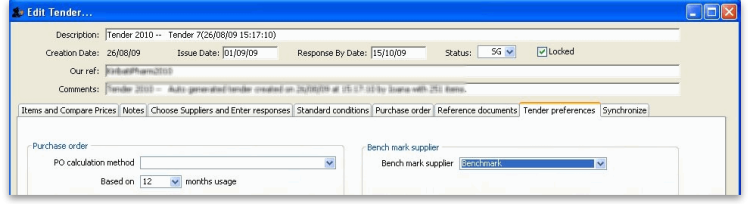

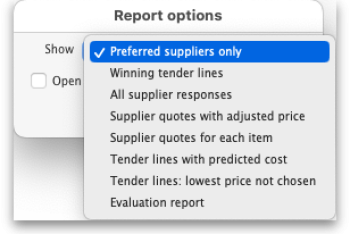

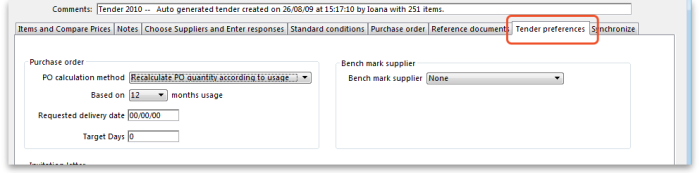

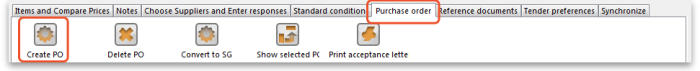

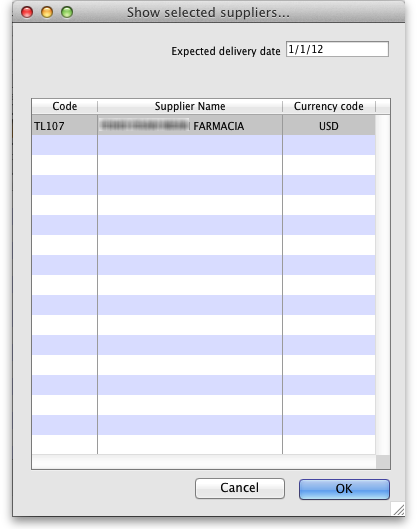

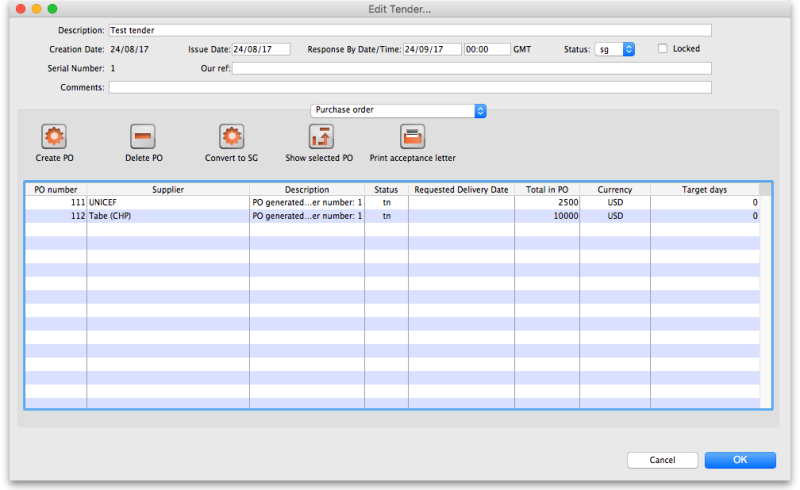

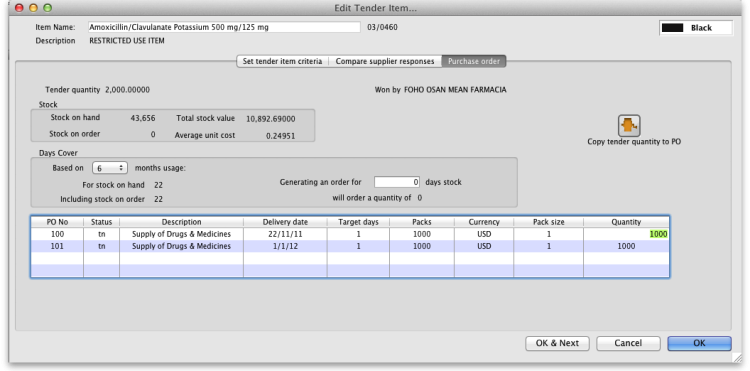

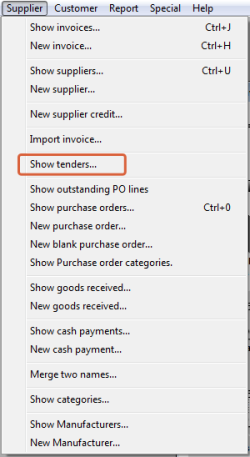

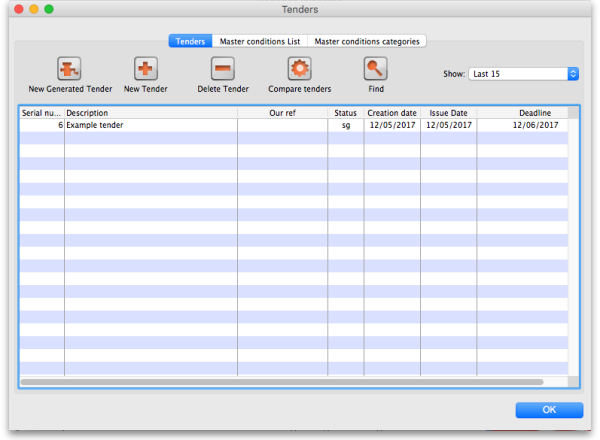

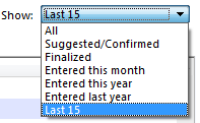

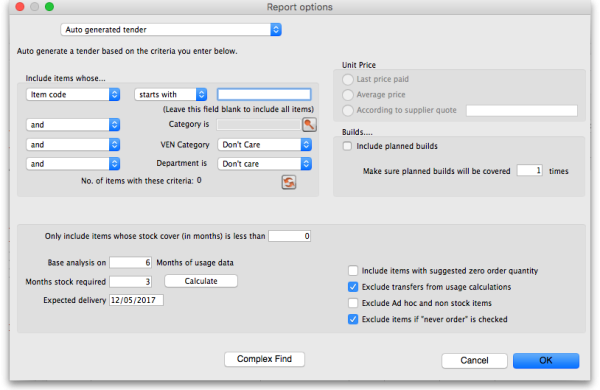

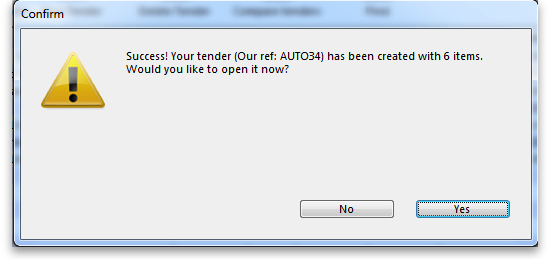

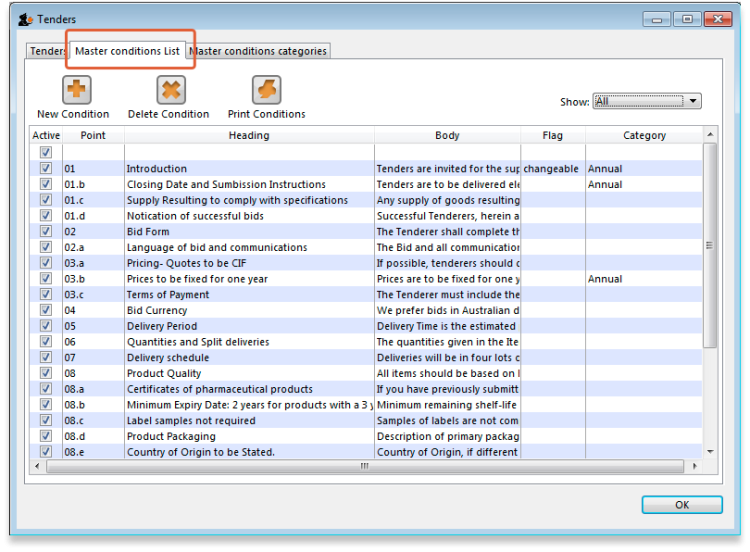

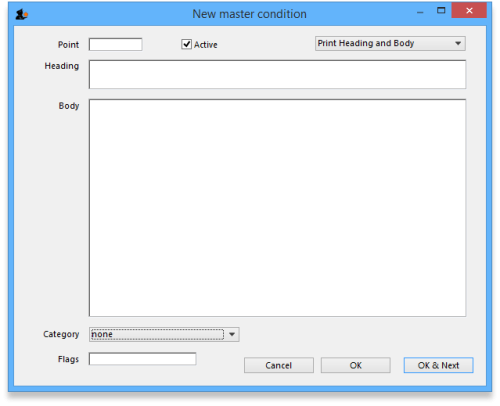

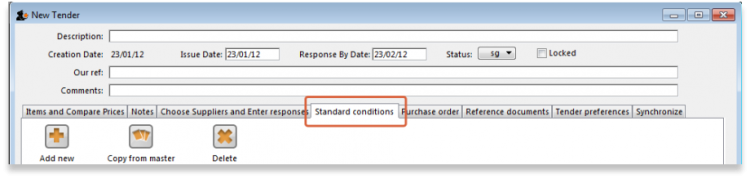

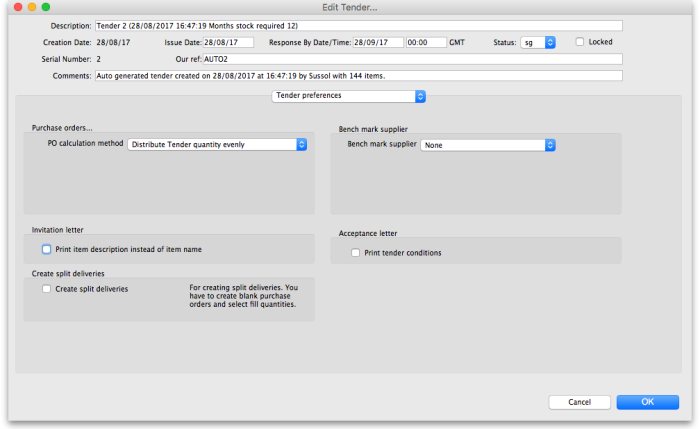

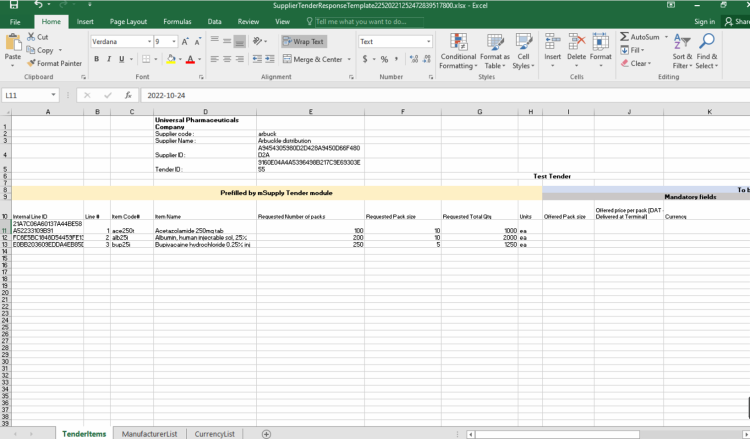

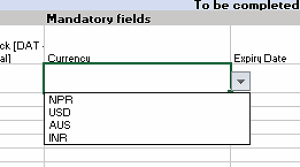

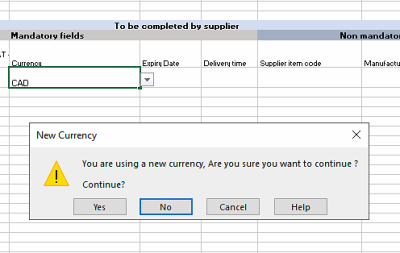

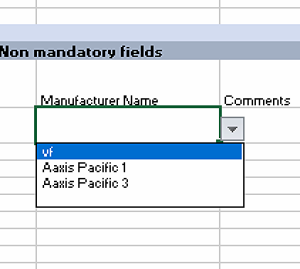

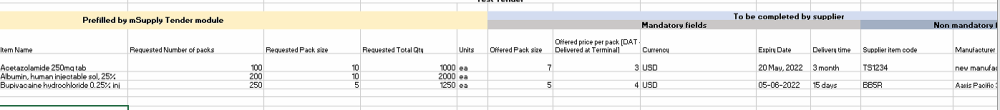

- The Tender Management module provides detailed production and management of tenders including using mSupply data to determine quantification, printing invitation letters, comparing tender submissions and automatically producing Purchase Orders for the winning tender supplier.

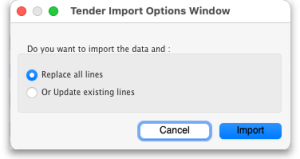

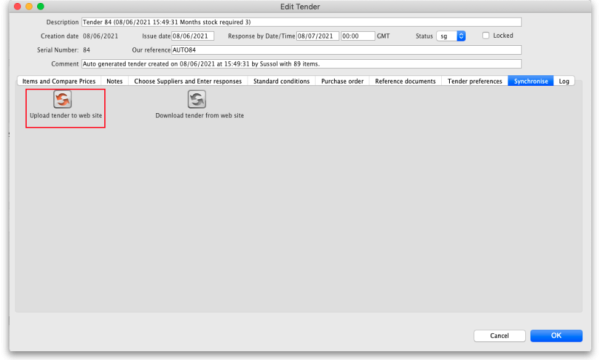

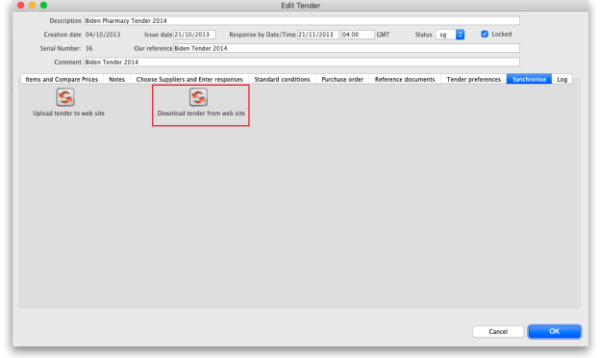

- The Remote Tender Management Module provides posting of tenders by suppliers to https://tenders.msupply.org.nz secure web site. You download and automatically import completed tenders to mSupply for easy comparison of supplier responses, choosing the winning supplier and creation of purchase orders.

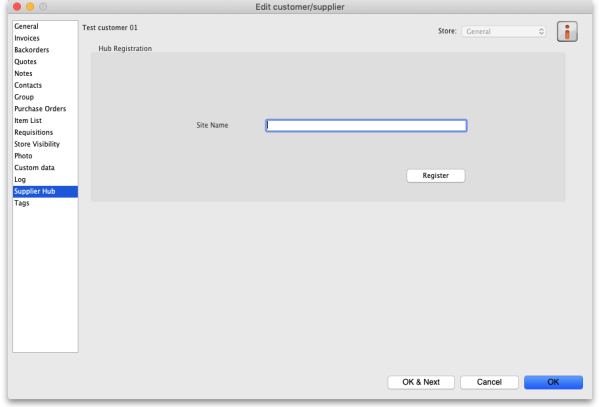

- Supplier Registration functionality is planned to be developed as part of the Tender management module.

Dispensing

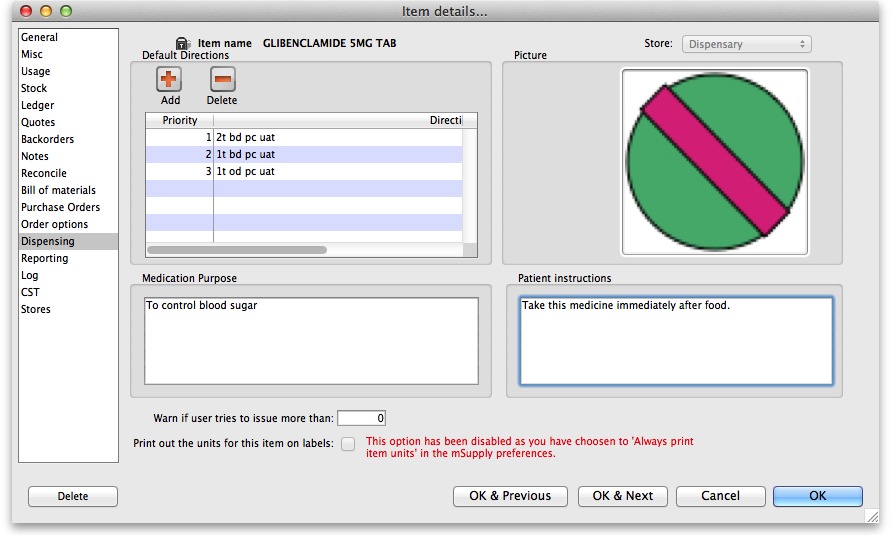

- mSupply integrates well into hospital pharmacies, providing easy breakdown of bulk packs for dispensing.

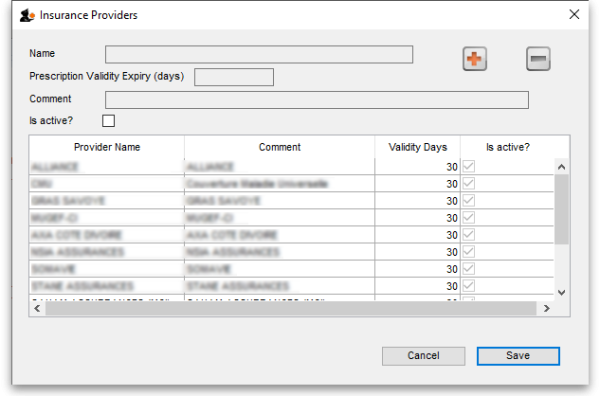

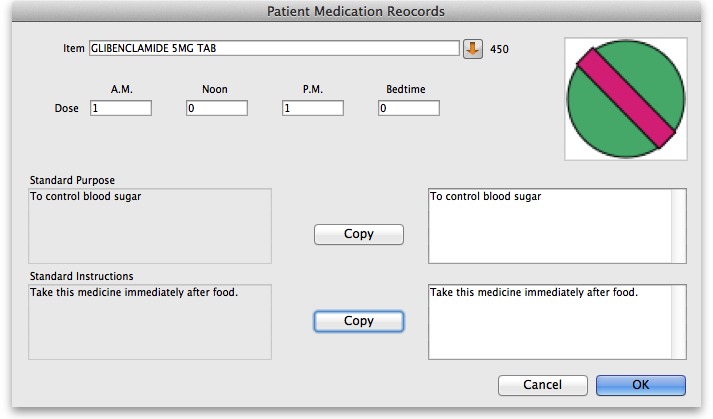

- Prescribers are recorded, and prescriber reports allow analysis of prescribing trends and costs.

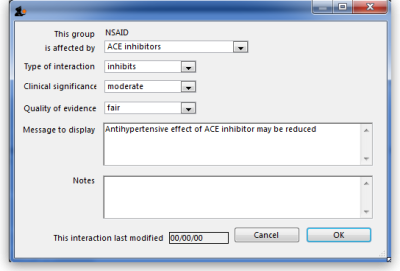

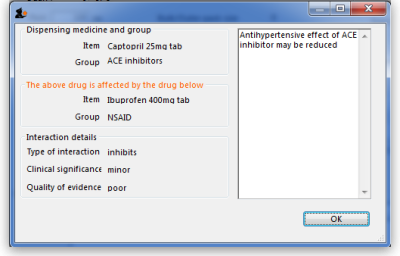

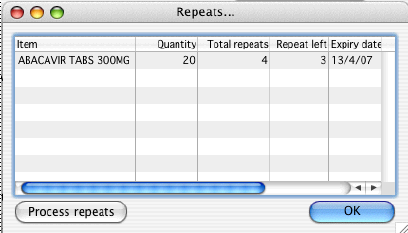

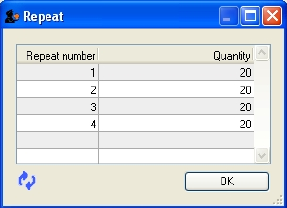

- Drug interactions are handled, as is repeat dispensing.

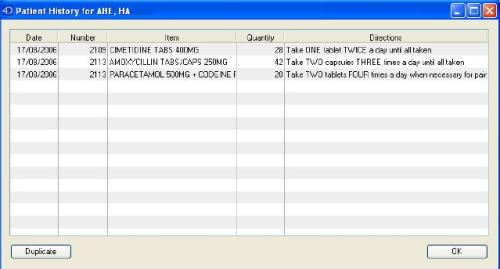

- Patient history is recorded and easily accessible.

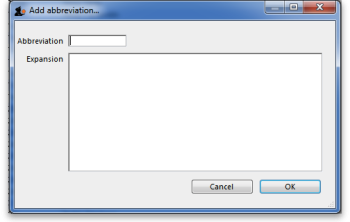

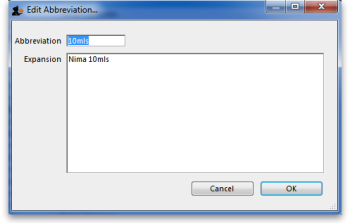

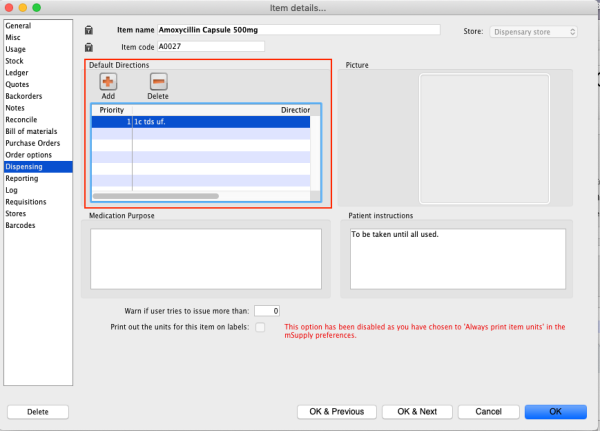

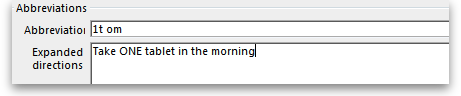

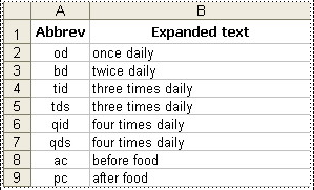

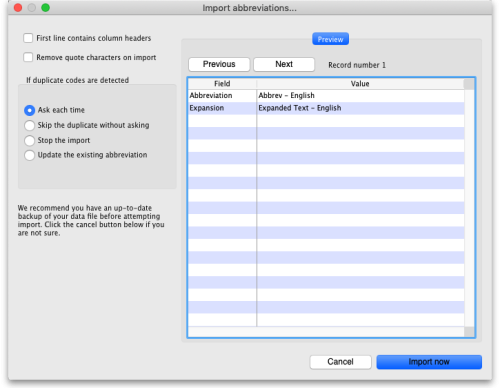

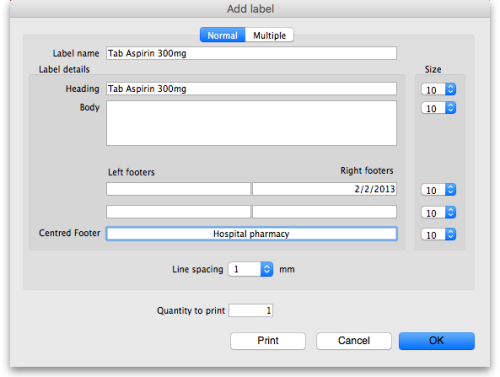

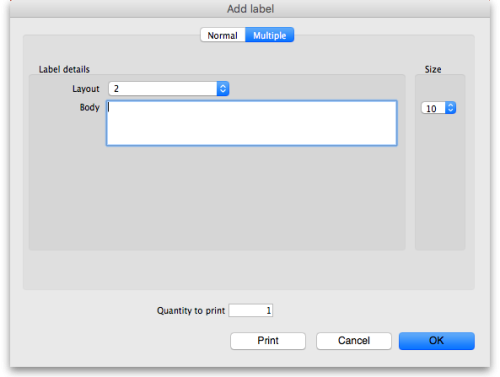

- Customisable abbreviations allow rapid entry of patient instructions on to printed labels.

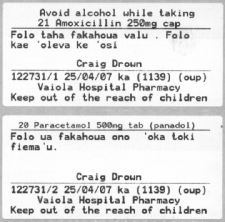

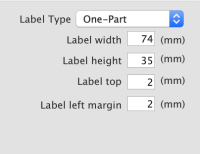

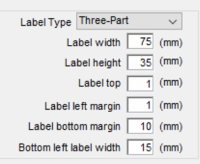

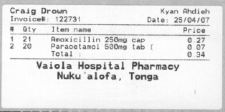

- Medicine labels are produced using specialist label printers. Busy sites using mSupply produce hundreds of thousands of labels per year.

Multiple sites from one server

- mSupply is able to handle multiple virtual stores within a single data file. A common use for this is a hospital, where several stores may be present, but each needs to run independently.

- Stores can run in either dispensary or store mode, so one server can handle both a hospital pharmacy and a warehouse store simultaneously.

- Using Citrix and a DSL internet connection you can run a whole country's medical distribution system from a single server, greatly reducing infrastructure requirements while dramatically improving availability and reliability.

Stock control

- Because mSupply tracks each batch separately, full FEFO 7) can be maintained for every item.

- There is a full audit trail for each stock line.

- Each stock line has a record of warehouse location, enabling easy warehouse management

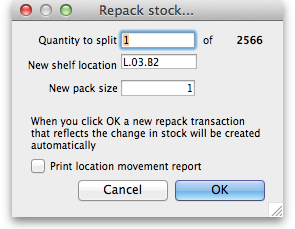

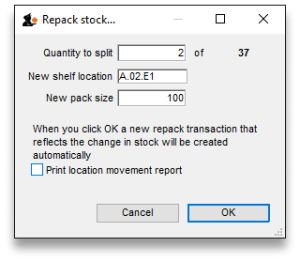

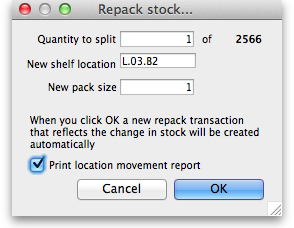

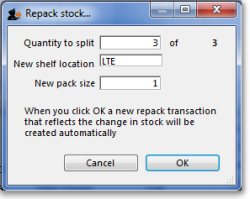

- If stock lines have the same batch number, expiry and pack size, they can be split and combined.

- Stock lines can be re-packed to different pack sizes for convenience. Warehouses will find it easier to handle cartons with a pack size of, say, 12,000 tablets while dispensaries will be dispensing individual tablets, and so will want a pack size of 1.

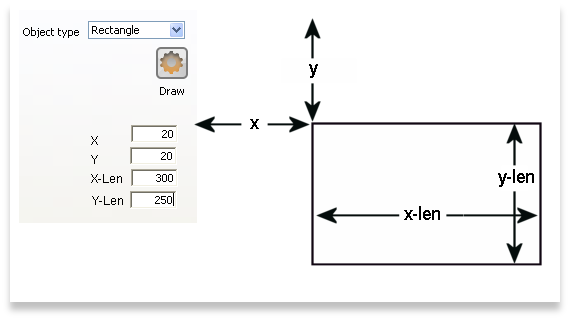

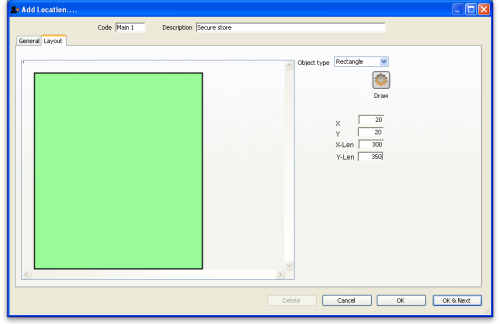

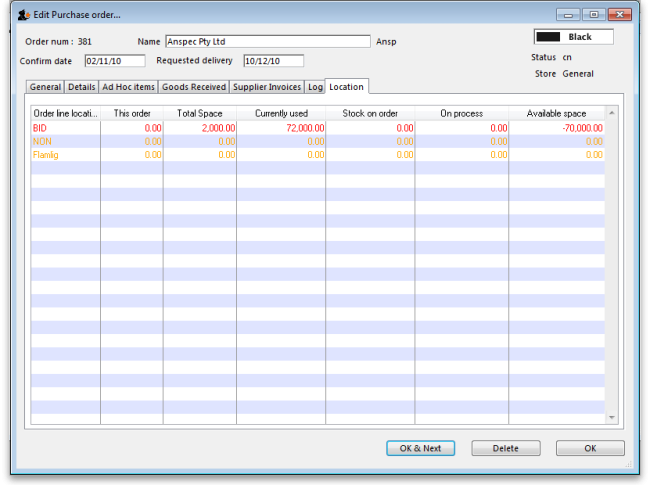

Warehouse management

- Full Location management

- mSupply allows volume based calculations of available storage, that is especially critical for cold chain items.

- Volume information is used to provide either reports or a graphical depiction of how full each section of the warehouse is.

- Alerts are given when placing purchase orders if there will not be enough space to hold the incoming goods.

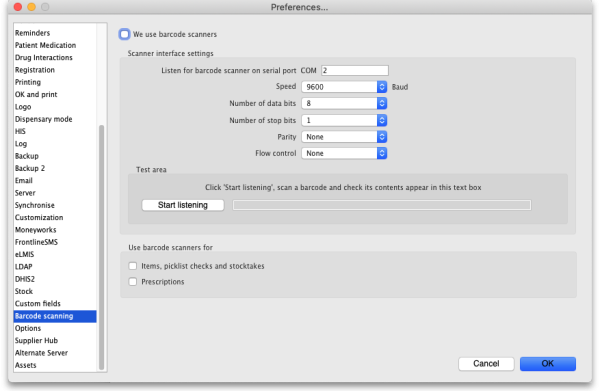

- Basic bar-coding functionality is planned to be developed soon.

Vaccines monitoring

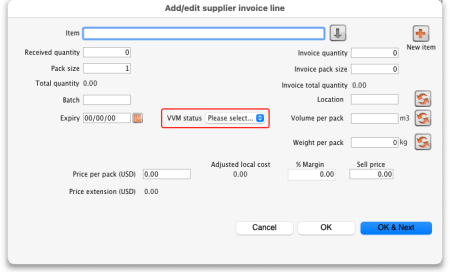

- mSupply allows recording of VVM8) status for batches, and allows sorting available stock by VVM status rather than by expiry.

Mobile communications

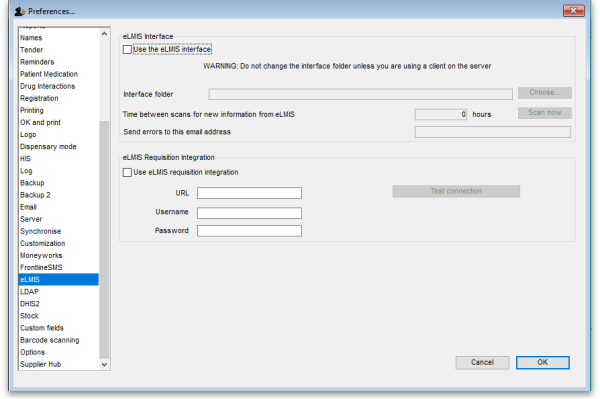

- mSupply integrates with Frontline SMS to provide an interface for using SMS messaging to submit information such as stock levels and goods receipt confirmations to mSupply.

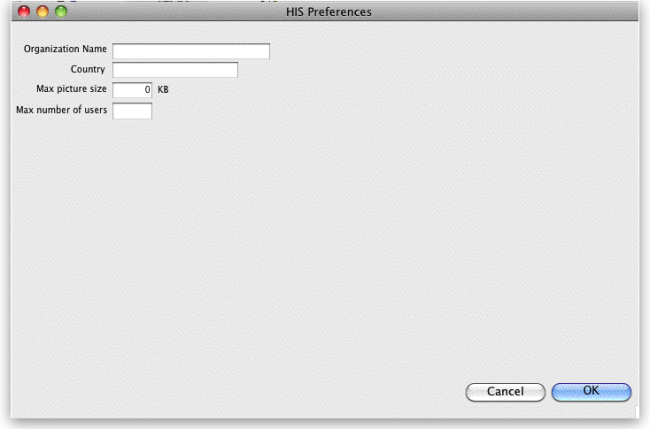

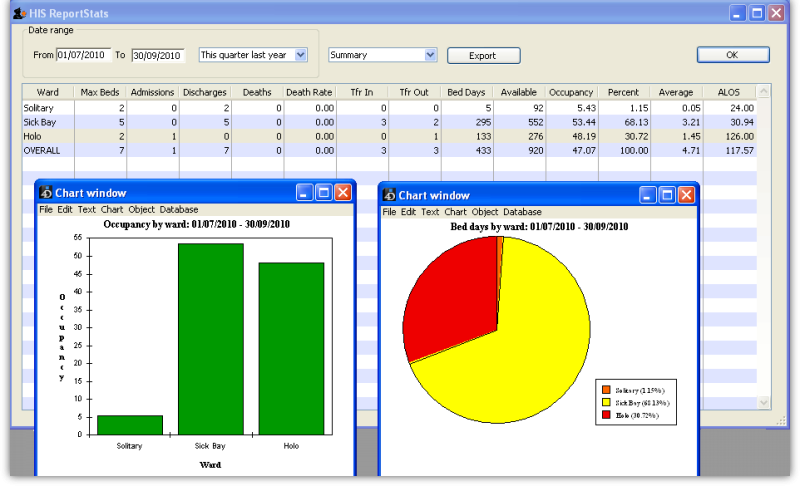

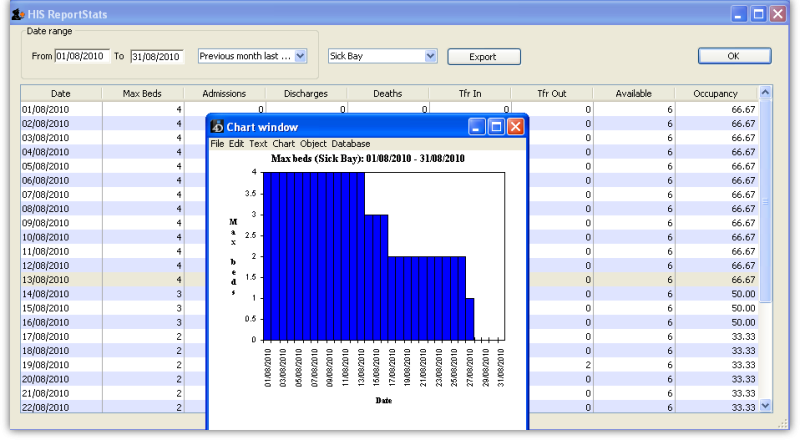

Hospital information system

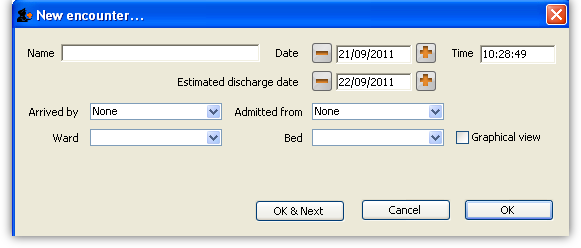

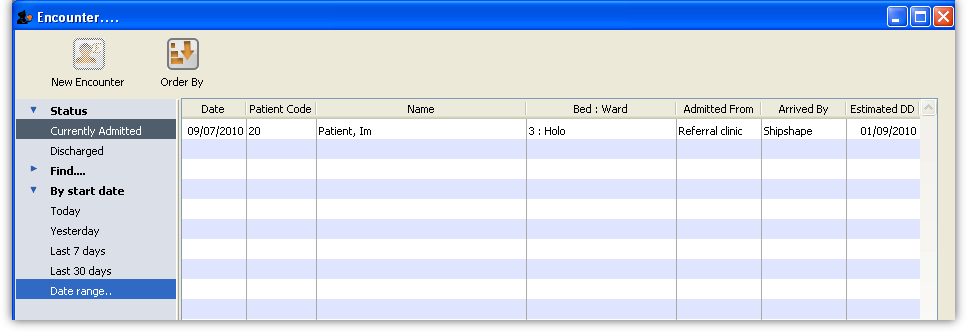

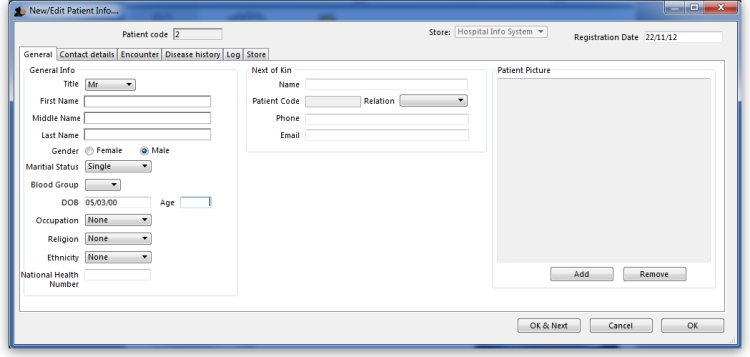

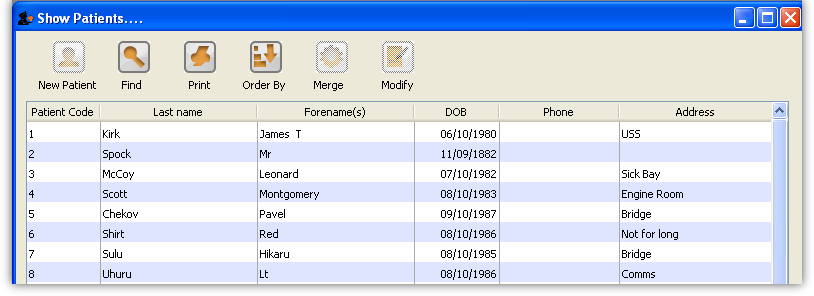

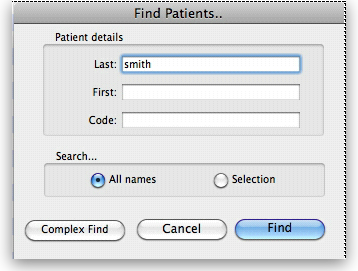

- A simple hospital information system has been developed as part of mSupply. It is designed to provide a basic service to record critical data:

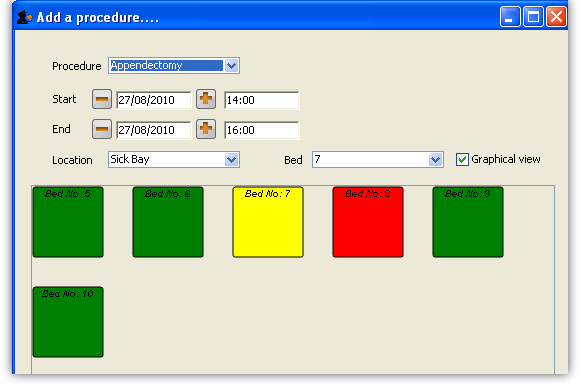

- Recording a hospital's wards and beds.

- Recording inpatient admissions (admitting a patient, assigning them to a ward and bed).

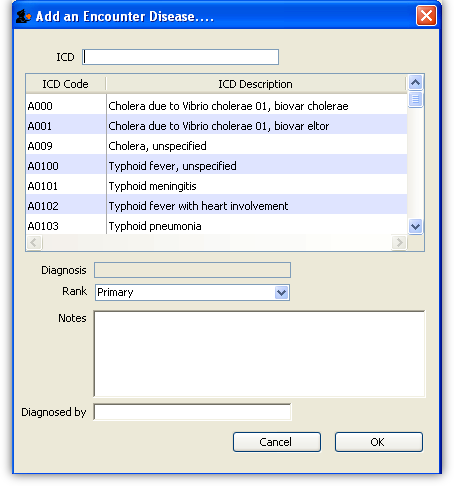

- Recording ICD9) 10 disease codes for each patient admission. You can assign multiple disease codes, and prioritise them (primary, secondary, etc..).

- Moving patients to different wards/beds.

- Recording discharge data (patient status at time of discharge)

- Reporting on bed occupancy rates as a whole and by ward, and other useful statistics e.g. average length of stay, ICD10 statistics.

- The mSupply HIS is a cost effective alternative to large commercial installations.

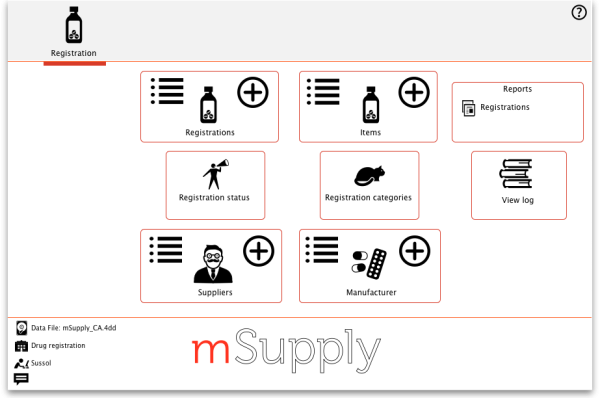

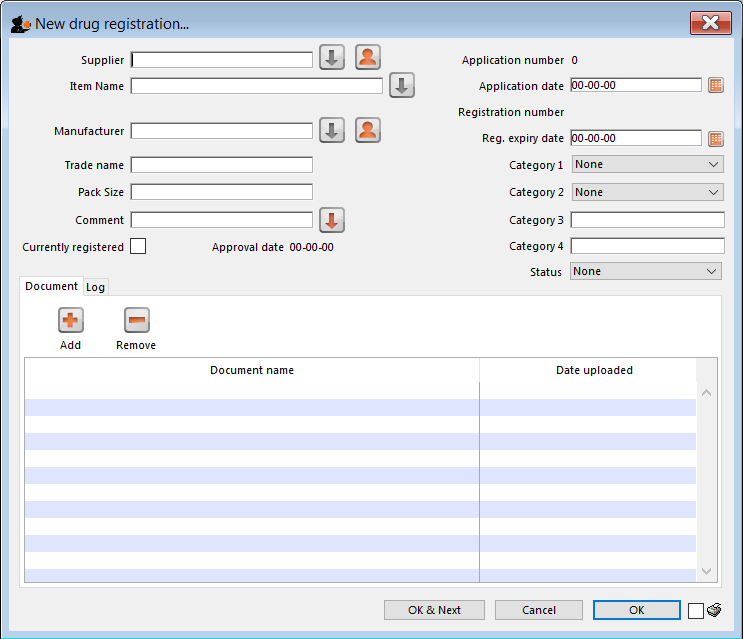

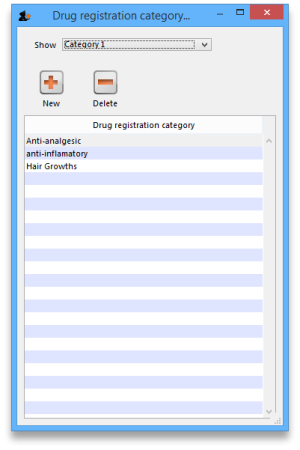

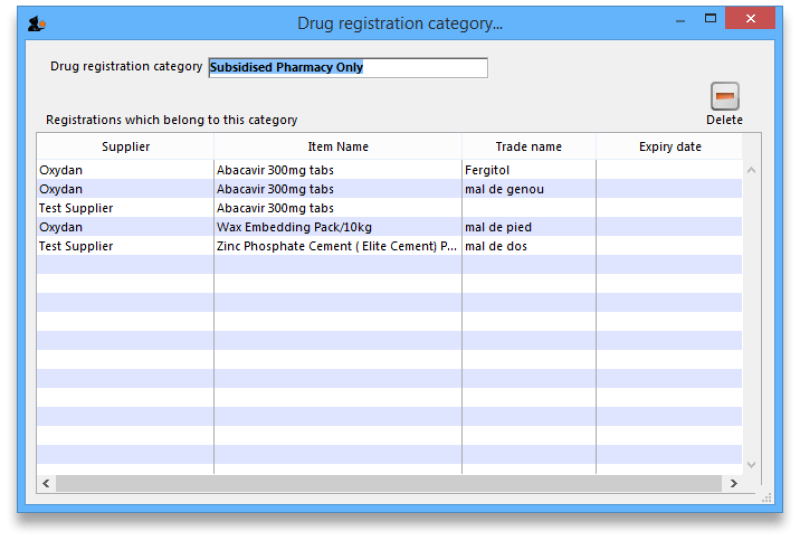

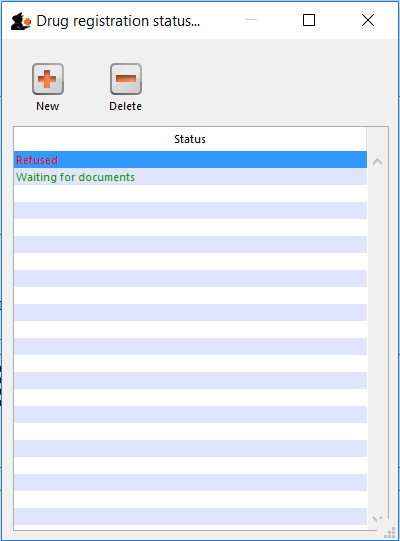

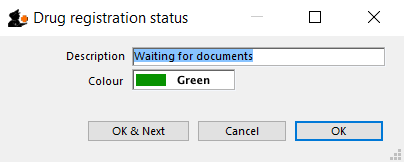

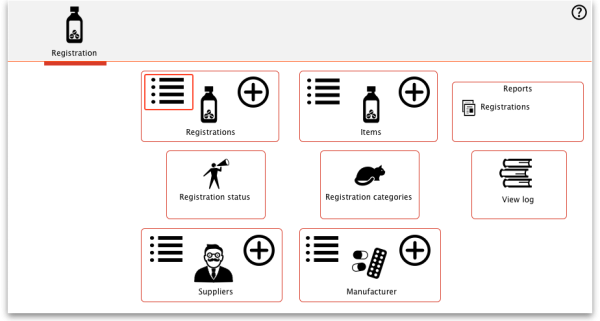

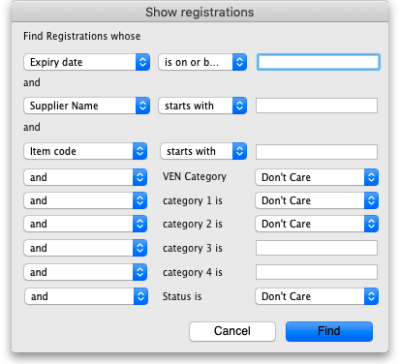

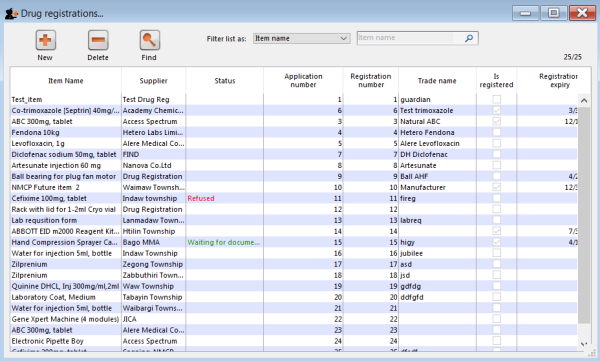

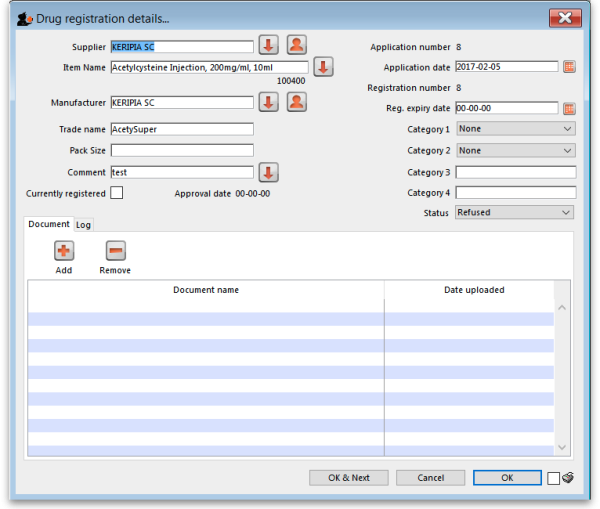

Product / medicine registration

- mSupply's Registration module allows mSupply to manage registration of suppliers and their products on a per brand, dose, and form basis.

- mSupply will record and track the status of supplier's registrations and stores the documentation for easy retrieval.

No data lock-in

- All data in mSupply can be exported as industry-standard XML or as an SQL dump, allowing use by other systems as needed.

- A public API has been developed, allowing any system to retrieve and submit information from/to mSupply.

Cross-platform

- mSupply is available for Windows and Macintosh.

- We recommend Windows servers, but client computers can be either Windows or Macintosh.

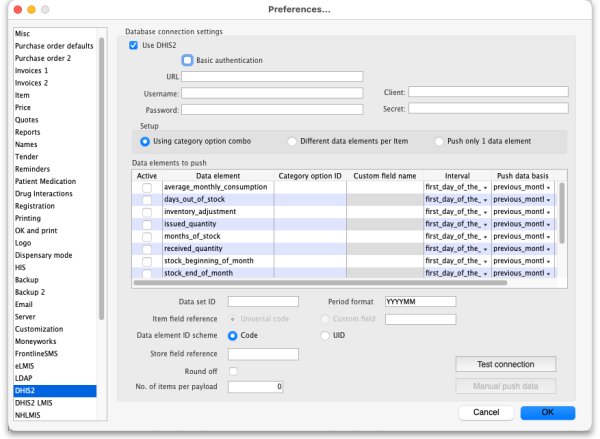

Interaction with other systems

- mSupply can either query other systems or provide data in real time via XML web services and other industry standard connectors.

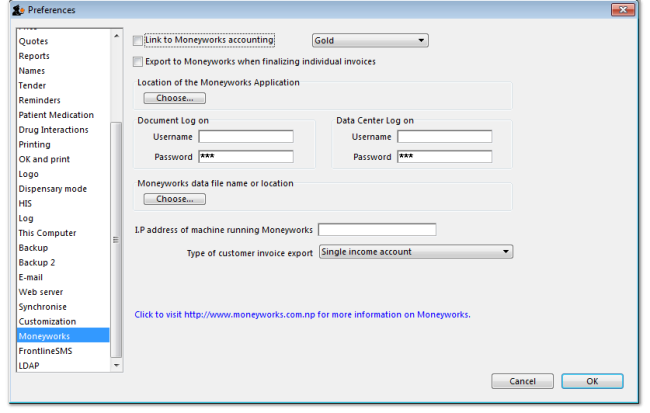

- mSupply provides automated seamless integration with Moneyworks accounting software and general export files which can be easily customisable for import to other systems.

All of these features combine to make a very powerful medical inventory supply chain management system which has been tried and tested in dozens of locations around the world. We believe it has a unique set of features that no other product offers for managing medical supplies in developing countries

For full information, visit http://www.msupply.org.nz A demo version is available here

The home page for the documentation wiki is here

| Previous: 1.01. Introduction | | Next: 1.03. Who uses mSupply? |

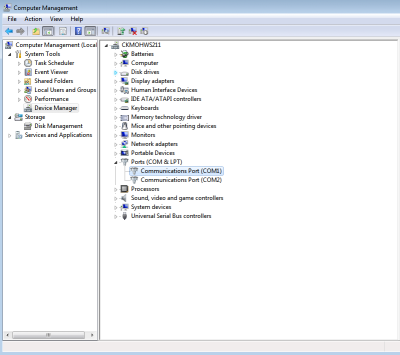

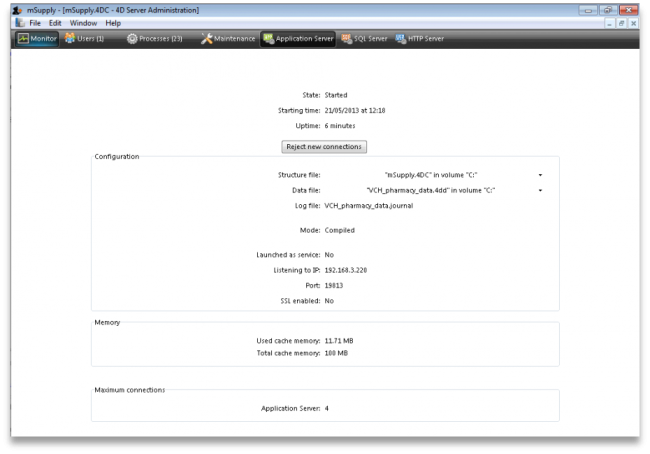

2.04. Client/Server FAQ

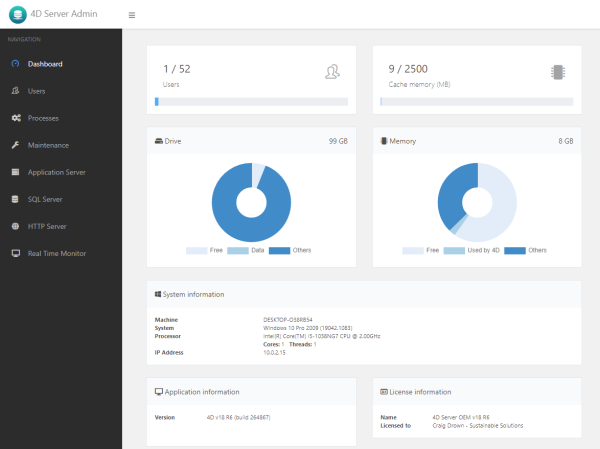

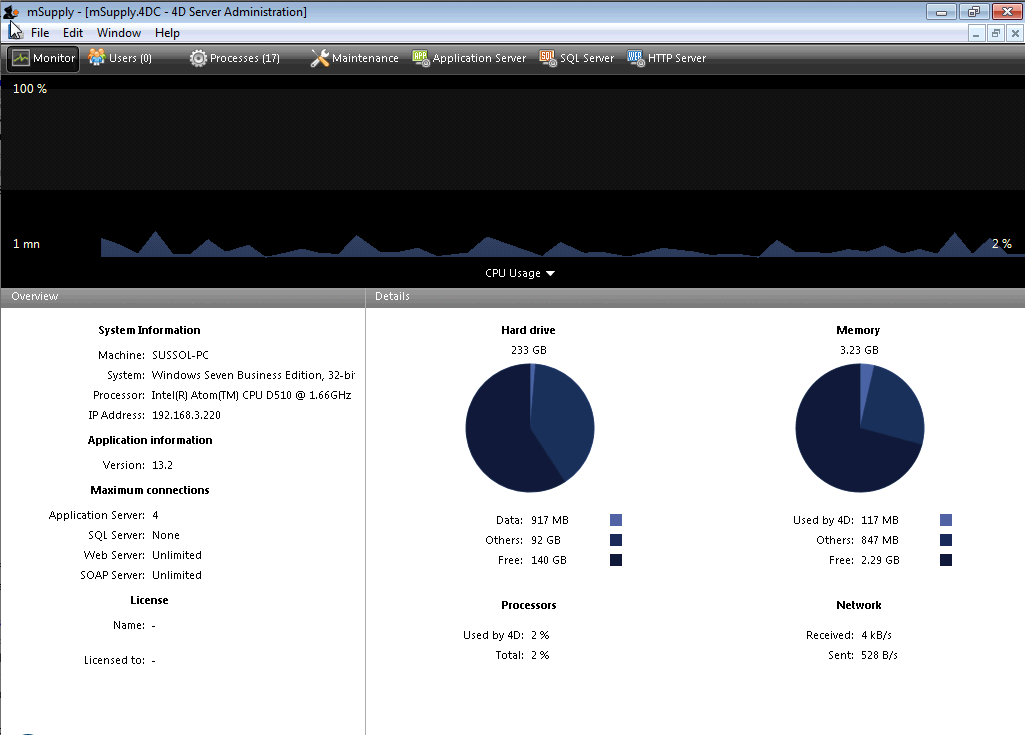

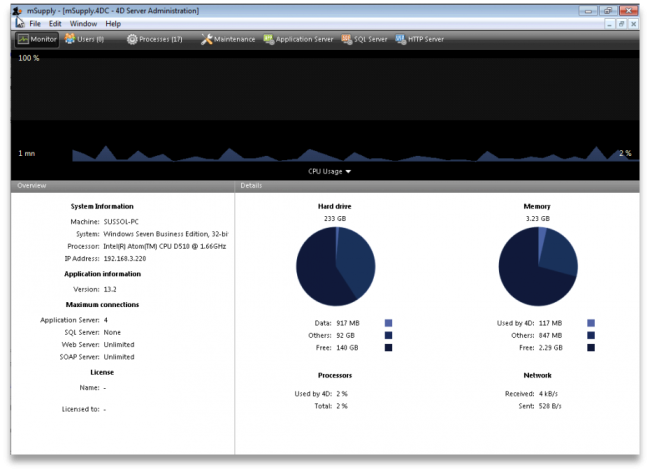

mSupply Server Requirements

OPERATING SYSTEM:

- Windows Server 2019 or above

- Windows 10 Pro can be used on laptop servers at smaller remote sites

MEMORY:

- New mSupply installation: 16GB minimum

- Migration of existing mSupply Server: multiply mSupply datafile size + index-file by 1.5 (e.g. datafile 20GB + index-file 2GB x 1.5 = 33GB RAM min)

PROCESSOR:

- 4 cores minimum

DRIVES:

- Root drive: 100GB min

- Data Backup: 100GB minimum allocated for mSupply backups (preferably on an additional volume rather than on the root drive)

NETWORK:

- Assign a local static IP address to server

BACKUPS:

- We can provide remote daily datafile backups to Backblaze cloud storage. We utilise an application on the server to encrypt all data before sending to the cloud storage so your is safe. This service will require urls to be whitelisted if your server restricts outbound traffic

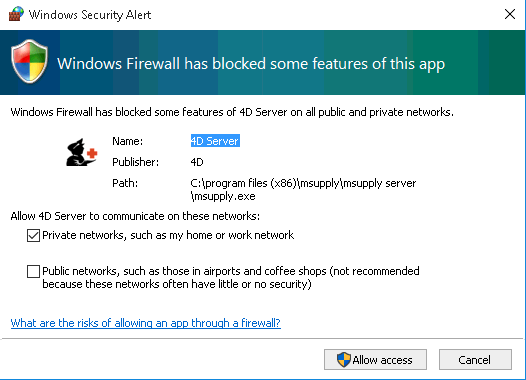

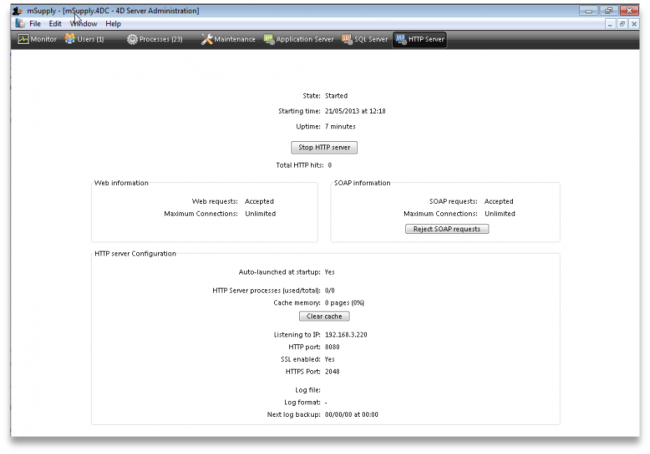

Port & Firewall Configuration

Central Sync Server

Our standard port configuration for an mSupply sync server (where remote sites need to connect to a central server over internet). Alternative ports can be used if required, for example if TSPlus remote kiosk access is not required then the mSupply web server can be configured to run over port 443

| Service | Allow Port | Protocol | Network | Requirement |

|---|---|---|---|---|

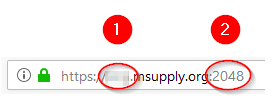

| mSupply Web Server | TCP 2048 | HTTPS | Public | mSupply web server traffic from remote mSupply sync sites |

| mSupply Dashboards | TCP 3000 | HTTPS | Public | mSupply Dashboard server traffic (if dashboards are to be accessible from the internet) |

| TSPlus Remote Web Kiosk | TCP 443 | HTTPS | Public | if running TSPlus for remote kiosk access to mSupply Client on the server |

| SSL renewal | TCP 80 | HTTPS | Public | Required for automatic SSL renewal via ACME http challenge (no other web traffic will use this port) |

| mSupply ColdChain API | TCP 8090 | HTTPS | Public | For mSupply ColdChain API (if used) |

| mSupply Application Server | TCP 19812, 19813, 19814 | Local | mSupply Client connections to mSupply application server over LAN | |

| mSupply broadcast | UDP 49157 to 65535 | Local | mSupply will automatically broadcast on the local network over this UDP port range to find the mSupply server |

mSupply Server (Central or Remote) with no syncing remote sites

All mSupply Client applications connect to the server over the LAN. There are no remote sites that need to sync to the central server.

| Service | Allow Port | Protocol | Network | Requirement |

|---|---|---|---|---|

| mSupply Application Server | TCP 19812, 19813, 19814 | Local | mSupply Client connections to mSupply Server over LAN | |

| mSupply Server broadcast | UDP 49157 to 65535 | Local | mSupply Server will automatically broadcast on the local network over this UDP port range so Clients can automatically find the server |

UDP Ports: If a local static IP address is assigned to the mSupply Server then mSupply Clients can be configured to find the server without needing to open the UDP broadcast ports. This Client configuration is covered in a section below

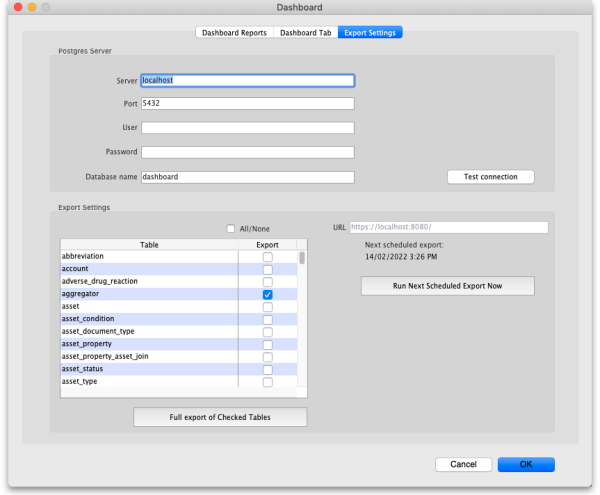

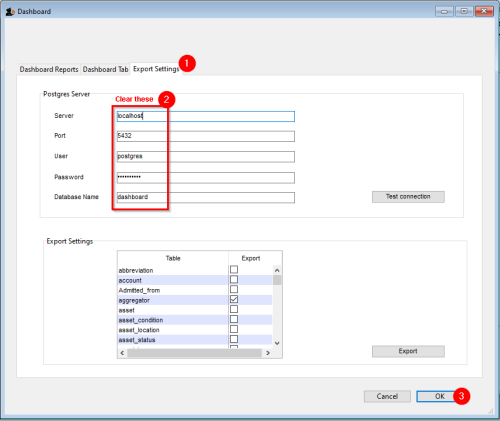

Separate Dashboard Server Instance

The mSupply Dashboard application uses a PostgreSQL database. It may be advisable to run the Dashboard and Postgres servers together on a separate server instance from the mSupply server so that each instance can be configured specifically for the application that it is running, and so server resources required by Postgres do not interfere with the smooth functioning of mSupply Server.

If mSupply Dashboards and PostgreSQL are running on a separate server instance to the mSupply Server the following configuration will be required for the dashboard server:

| Service | Allow Port | Protocol | Network | Requirement |

|---|---|---|---|---|

| PostgreSQL | TCP 5432 | Local | export of data from the mSupply db to the Postgres dashboard db | |

| mSupply Dashboards | TCP 3000 | HTTPS | Public | mSupply Dashboard server traffic (if dashboards are to be accessible from the internet) |

mSupply Client Requirements & Configuration

OPERATING SYSTEM:

- Windows 10 64 Bit

MEMORY:

- 4GB minimum, 8GB recommended

If the UPD ports on the server are not open, or the mSupply Clients are on a separate subnet to the mSupply Server, then the Clients will not automatically find the Server. In this case the Server will require a static local IP address (which is good practice either way).

There are two methods to direct mSupply Clients to the IP address of the mSupply server:

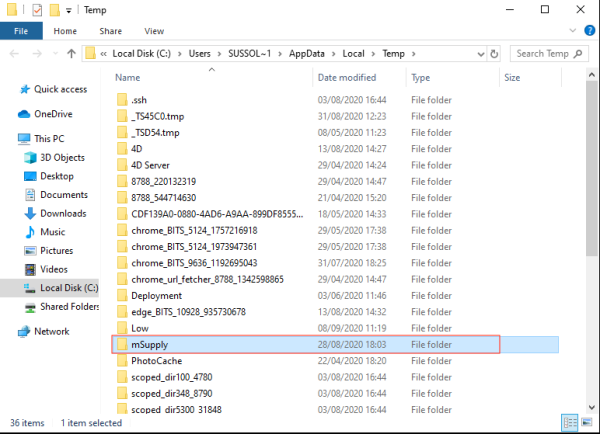

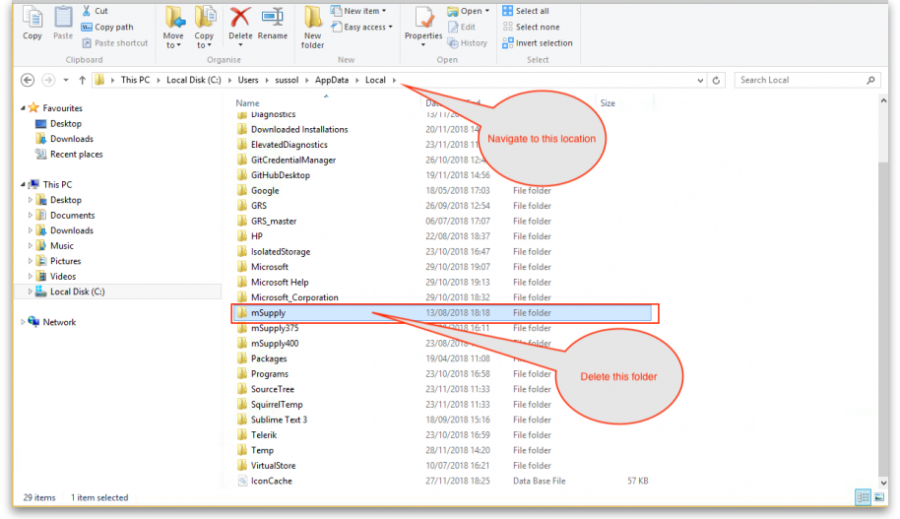

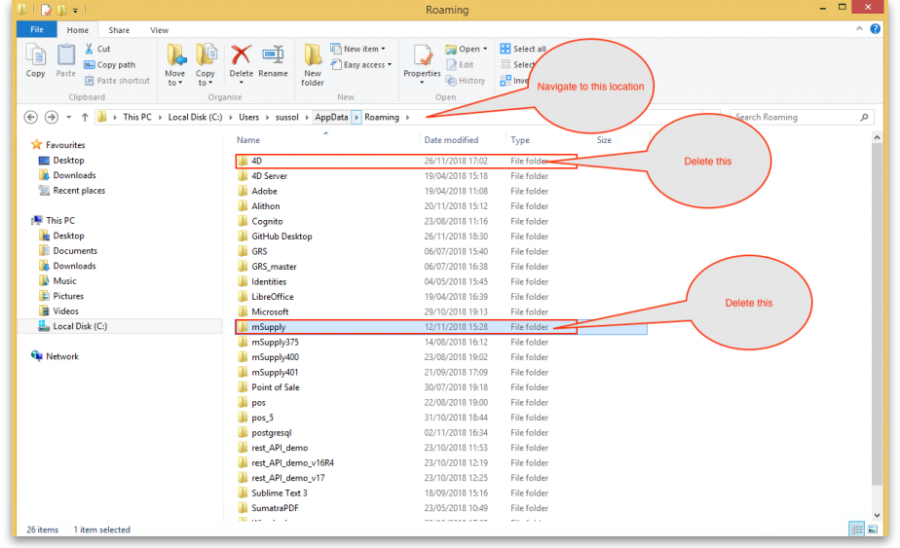

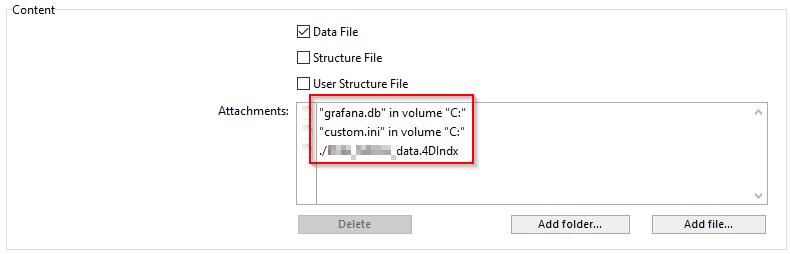

1) Client configuration file

After mSupply Client has been installed edit the EnginedServer.4Dlink found at this path C:\mSupply client\Database using notepad. Replace <SERVER IP ADDRESS> in the code below with the Server IP. This same edited file can then be deployed to the client database folder of all the mSupply Client installations on this LAN.

<?xml version="1.0" encoding="UTF-8"?><database_shortcut is_remote="true" server_database_name="mSupply" server_path="<SERVER IP ADDRESS>:19813" cache_folder_name="mSupplyClient"/>

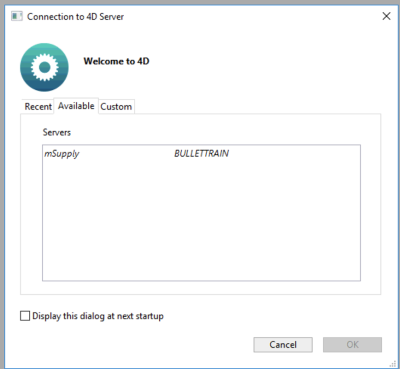

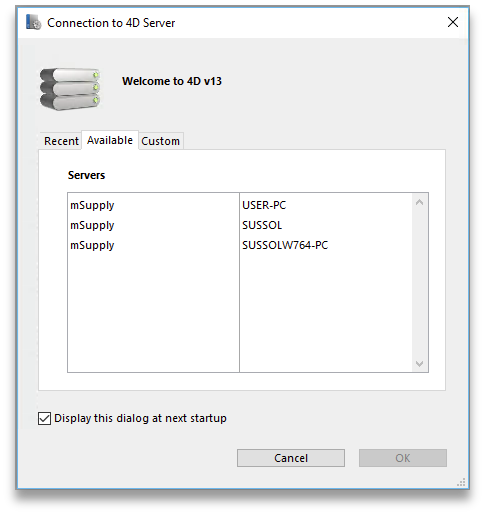

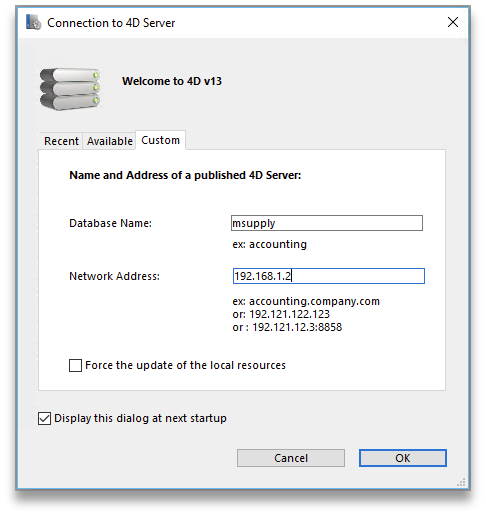

2) Client Server Connection Window

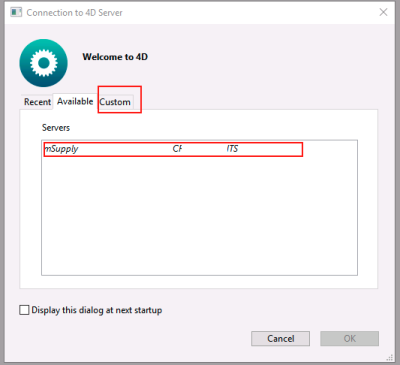

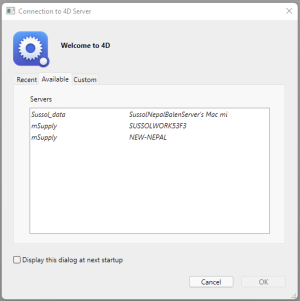

- Double click on the mSupply client icon but hold down the alt key just after double clicking (This will open Connection to 4D Server window)

- Go to the 'Custom' tab as per the screenshot attached

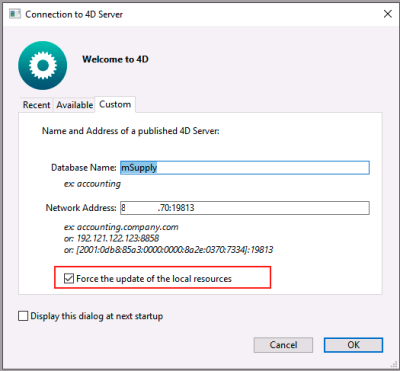

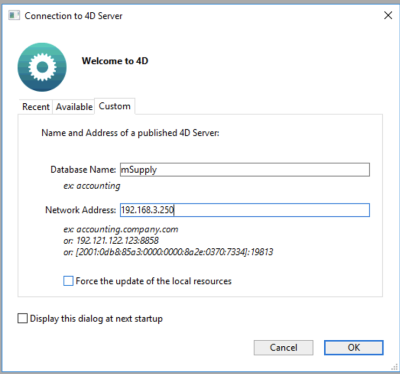

- In project name field enter mSupply

- In the Network address field enter the server ip address

- Click OK (if Client successfully connects the connection config will be saved and this process will not need to be repeated)

Standard Sync or Mirror Sync?

For more information on both our standard sync and mirror sync setups please see this page of our docs

2.02. Installation

Synced system

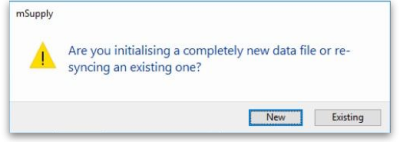

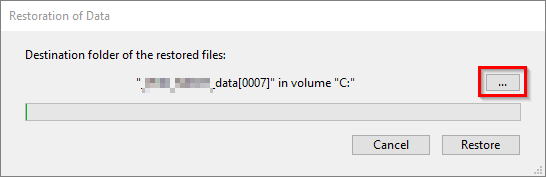

If you are installing mSupply within a synced system, then it is quite likely that you should not be installing the single-user version as described in the section below. The instructions to follow depend on which sort of site you are installing:

- Single-User sync satellite site:

- Contact the mSupply Foundation support to obtain the correct version of mSupply Single-User. It may not be the version on the mSupply Downloads web page

- Then follow the instructions for Sync Site Import

Contact mSupply Foundation support for clarification: support@msupply.foundation

Single-User system

We are assuming you have obtained mSupply from the mSupply Downloads web page.

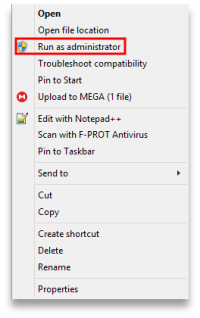

- If you are using a Windows machine, you have downloaded the file you need, and you have saved it to your desktop, it is important that you saved the file with an

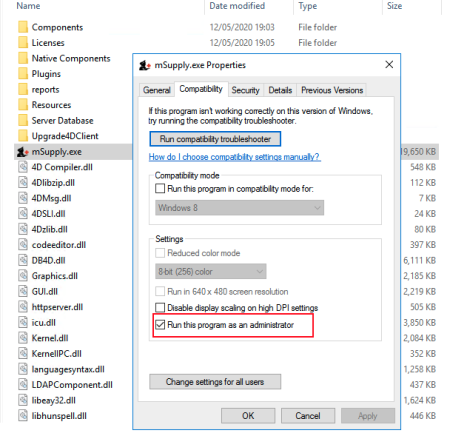

.exeextension or it will not run. You can rename a file by right-clicking on it. The name of the file should be something likemSupply_Single_User_V4-07-09. - It is possible to allow mSupply to be run from multiple Windows accounts (e.g. admin and non-admin accounts). However there are a few precautions / tweeks:

- If you are switching between admin and non-admin accounts, you will need to close mSupply before switching. Single user is intended to be used on one account at a time, and will throw an error if already open on another account.

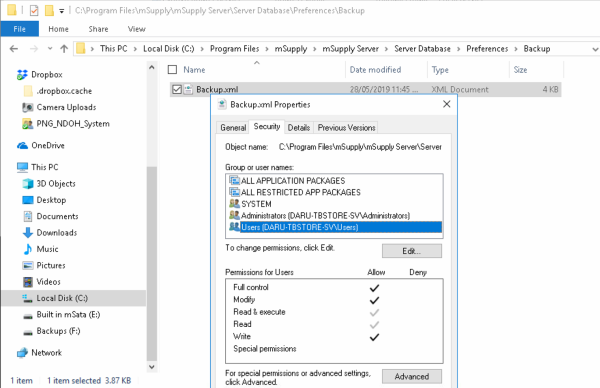

- Data file location needs to be in a commonly accessible location, e.g.

C:\mSupply_Datafile. - Any backup location needs to be in a commonly accessible location, e.g.

C:\mSupply_Backup.

It is strongly recommended that users who are not familiar with program installation adhere to these directions.

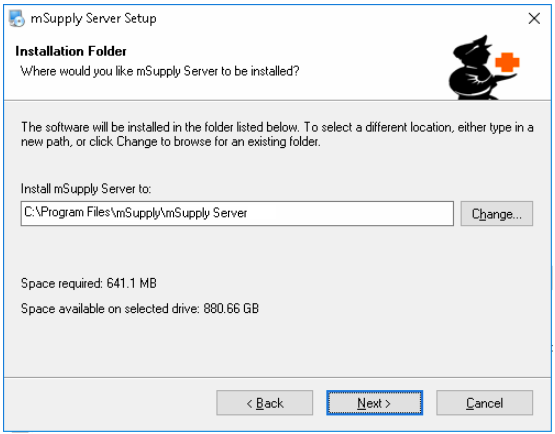

- Double-click the installer and it will automatically run the mSupply installer.

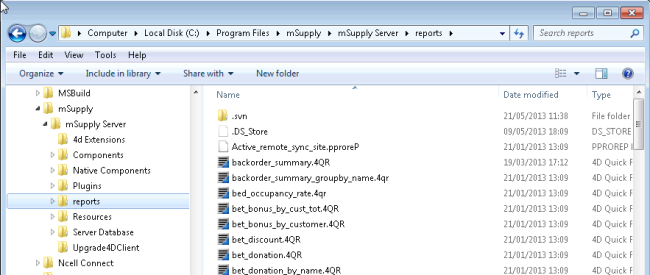

- The installer will do the following:

- Create a folder on your chosen drive called “mSupply”

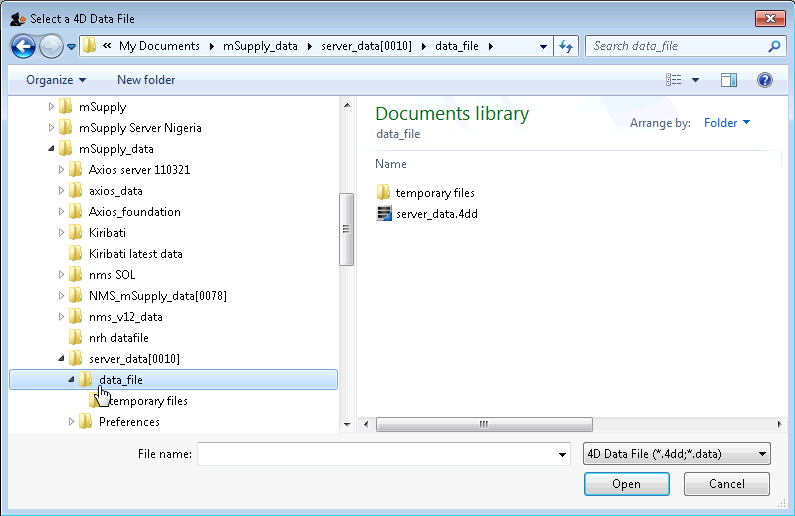

- On Windows the example data file is installed in the My Documents/mSupply/Example sub folder.

- NOTE: You can use this data file for practice. (Or use the tutorial at the start of the manual to learn the basics quickly)

- Install the “mSupply.exe” application and associated files. Double-clicking this file will do the same as double-clicking the “start mSupply” icon on your desktop.

- Install readme.txt - information on licensing and using mSupply.

- Create a shortcut on your desktop: start mSupply

- Create a mSupply folder entry in the Programs section of your Start menu.

Now you are ready to begin! Proceed to the section below on starting the example database.

Example data file

The mSupply installer treats Example data files in a special way. Re-installing mSupply on a previous installation will replace all the files except the Example data file. This is to prevent valuable data from being deleted as users may have started entering actual stock into the Example data file.

To install a fresh copy of the Example data file on Windows you can carry out one of the options described below:

- Un-install mSupply using the Windows menu Start > Program Files > mSupply > Uninstall mSupply . This will remove all installed files of mSupply which includes the Example data files. Re-installing mSupply now will install a fresh copy of the Example data file.

- You can manually delete the Example data file and re-install mSupply. The mSupply installer will install a fresh copy of the example database as the previously installed file has been deleted.

On Macintosh machines, simply replace the Example folder from the mSupply installer image.

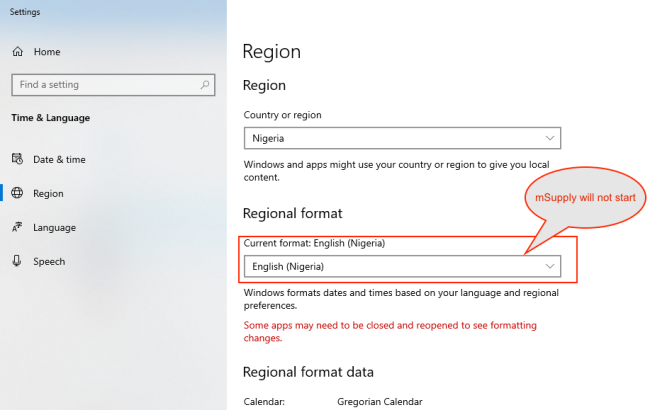

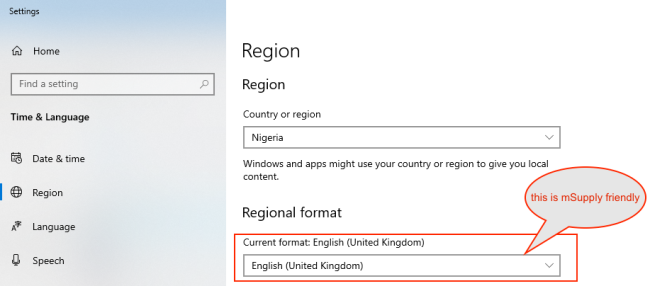

Notes for Windows users

Date format

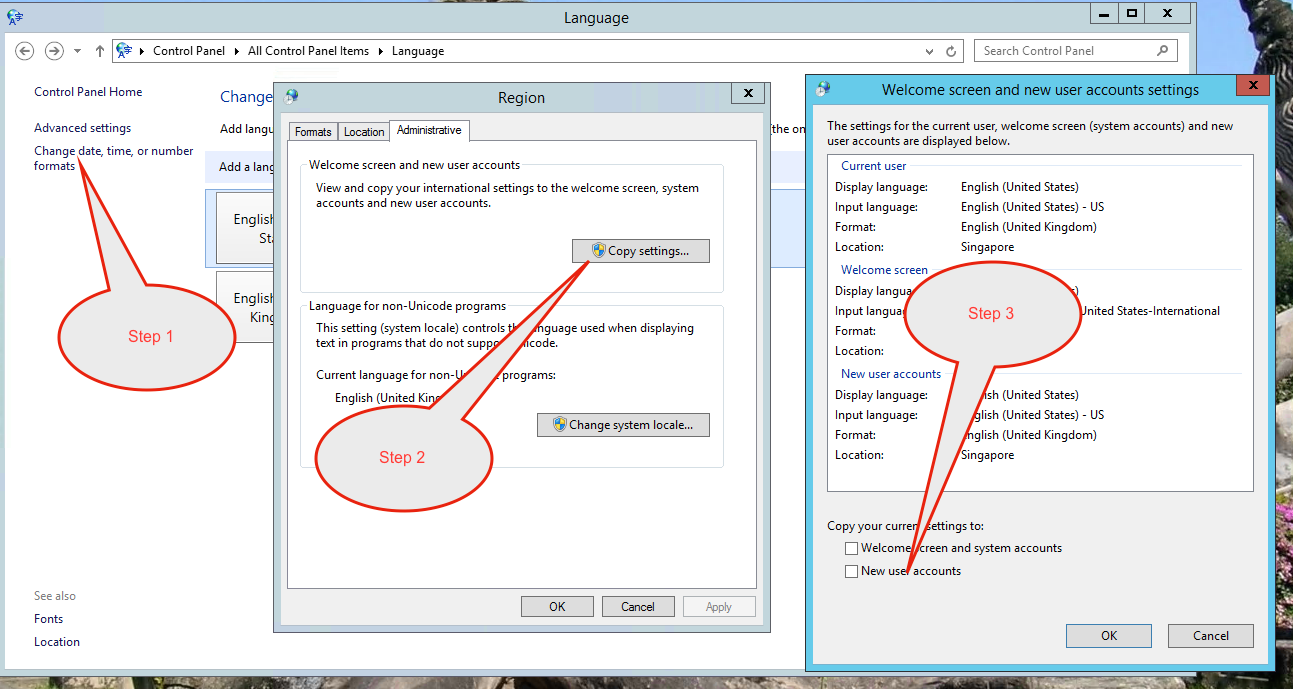

- In the regional settings in Control Panel, we recommend that the short date format is set to display only 2 digits for the year (YY, not YYYY).mSupply lists are set up to allow only enough space for 4 digits with most font sizes, but occasionally 4 digit years may be truncated. Having the wrong setting here will only affect display, not the actual data. It does not matter if you use DD/MM/YY or MM/DD/YY or YY/MM/DD

- If the display of lists in mSupply overlaps the separator lines, turn off large font in the display control panel.

| Previous: 2.01. Requirements | | Next: 2.03. Starting mSupply for the first time |

2.01. Requirements

For mSuppy Mobile, refer Requirements

For more detailed configuration information on mSupply Client/Server setups please see this FAQ page

Hardware requirements

General hardware recommendations

We have clients running mSupply on a wide range of hardware in a wide range of operating environments. We are happy to discuss hardware options further - please contact support@msupply.foundation, but here are our general recommendations:

- In environments with regular power outages, which is most institutions using mSupply

, it is highly recommended to procure Laptop machines rather than desktop machines - refer to why we now recommend that you use laptops below.

- A connected printer is not absolutely necessary in every situation, but for most situations it is a requirement. A laser printer or an ink 'tank' printer is preferable.

- Buy hardware for which good after sales support is available.

- Buy brands with a reputation for quality (even if it means buying a slower/older machine).

Hardware Requirements

Windows 10 is no longer supported by Microsoft, but Windows 10 still works with mSupply (for now). Please visit Microsoft Windows 11 system requirements to see if your system is eligible to upgrade to Windows 11.

As of version 7.17 and above, Mac OS is no longer supported for mSupply Client.

Hardware requirements vary widely depending on what you want to use mSupply for. Here's a rough guide:

| Machine | Minimum | Recommended |

|---|---|---|

| Windows Client Machine (For use with server) | 64 bit, Intel i5 or AMD Ryzen 5 Processor, 16GB RAM, 120GB of disk space, Windows 11 (or higher) | Intel i7+ AMD Ryzen 5+ Processor, 16GB+ RAM, 256GB+ of disk space |

| Windows Central Server (Central server on a synced system) | 64 bit, Intel i9 or AMD Ryzen 9 Processor, 32+ GB RAM, 4 x SSD/HDD volumes, 3 configured as RAID1 or RAID5 with hot spare plus daily backups to the fourth volume plus daily off-site backups, Windows Server 2016+ | Cloud hosted on a reputable service, Windows Server 2022 or above |

| Windows Remote Server (Remote server) | 64 bit, Intel i7 or Ryzen 7 Processor (or better), 16 GB RAM, 500 GB NVMe/SDD volume with daily backups to an external volume plus daily off-site backups, Windows 11 (or higher), Attached to a Smart UPS (see below) | 64 bit, Intel i9 or Ryzen 9 Processor (or better), 32+ GB RAM, plus regular off-site backups, Windows 11 (or higher) |

| Windows Single-User Machine | 64 bit, Intel i7 or Ryzen 7 Processor, 8 GB RAM, 256GB HDD/SDD volume plus daily backups to an external volume plus daily off-site backups Windows 11 (or higher) | 64 bit, Intel i9 or AMD Ryzen 9 Processor (or better), 16+ GB RAM, 500GB HDD/SDD plus daily backups to an external volume plus daily off-site backups |

For a Terminal server, the general specification changes in that

- More RAM is needed.

- Hard disks are less important, as no data is stored on the server (unless you are using the same server for both hosting the mSupply server and hosting the terminal sessions).

- An additional Gigabit Ethernet port could be useful

If you are running a server that is not in a datacentre with proper power protection: Beware of Solid State Drives (SSDs) without Power Loss Protection!

At least one country using mSupply on servers in health facilities with SSDs installed has had the bitter experience of the SSDs failing after ungraceful shutdowns due to failing UPSes.

The vast majority of ICT documentation on the internet is written from and for locations enjoying relatively stable power supplies. When the above-mentioned experience happened, there was precious little information available for facilities suffering from the sort of chronic power supply issues which the majority of mSupply users experience. Now there is more literature - refer here : Surviving SSD sudden power loss

We now recommend that you use laptops

Laptop machines, preferably with long battery life, will almost always be the best solution in terms of both cost and effectiveness. See below for the reasons why.

The problem with power cuts and UPSes

In our experience, the primary cause of mSupply database corruption is ungraceful shutdowns of the computer hosting the mSupply database. Ungraceful shutdowns occur when power to the computer is cut instantly, without any notification to the computer to shut down gracefully.

Ungraceful shutdowns on client computers will not result in mSupply database corruption. They may result in incomplete data record entry, but that can be rectified once power is restored.

A common mitigation to prevent ungraceful shutdowns is to use an Uninterruptible Power Supply (UPS). If the computer is protected by a normal UPS, then we can still have ungraceful shutdowns when the battery power runs out. A 'smart' UPS detects when the battery power is about to run out and sends a notification to software on the server which triggers a graceful shut down of the computer. To enable this, there needs to be a cable connection (normally USB) between the UPS and the computer combined with software running on the computer. Even if the machine is protected by a smart UPS, there are a number of circumstances where this UPS protection fails:

- Cable becomes disconnected

- Software isn't configured correctly or doesn't start up

- UPS batteries degrade (normally within 2 years of installation in environments with regular power cuts) and there is too little capacity to run long enough for the computer to shut down gracefully after receiving the notification from the UPS

The merits of laptops

Laptop computers tend to be much more resilient to power failure:

- A laptop's built-in 'smart' UPS is very reliable

- The internal batteries last much longer than UPS batteries

- Even if the laptop internal battery degrades, the 'smart' function appears to work much more reliably than a standalone UPS communicating with a 'tower' computer.

Here are some additional advantages of laptops vs. desktop computers:

- Can be more resilient to hot and humid working environments if you buy the right model.

- Lower cost of freight:

- To send the machine to site

- To send spare parts for repair on-site

- To retrieve the machine from site for any repairs that can not be undertaken on site

There are countries using mSupply where the cost of sending a 40kg traditional server computer to the site is comparable to the purchase price of the server.

- Wi-Fi capability normally included without extra cost

- Bluetooth capability normally included without extra cost

- 'Sound card', speaker, earphones and video camera normally included without extra cost

Battery life

While the consequences of running out of battery power on a laptop is not as catastrophic as on a desktop machine, it is still good to be able to keep your mSupply system running through long power cuts. Unfortunately most laptop manufacturers don't advertise how long their batteries last, even if they do last a long time! Fortunately, there are websites with reviews on laptops where the battery life has been tested and reported.

Security

A concern with laptop computers is security. It is easier to steal a laptop computer from an office than it is to steal a desktop computer. For this reason, laptops are normally configured with a physical locking feature such as Kensington lock slot or Noble wedge lock slot. Don't buy a laptop without one of these security lock features.

Keyboard

Because mSupply is dealing with lots of numbers (quantities of stock), it is highly recommended to have a keyboard with a numeric keypad. Smaller laptop computers (14“ screen or less) will not have this. Smaller laptop computers normally have an impractically small screen. It is therefore recommended to procure either:

- A laptop computer with a keyboard that includes a numeric keypad - which will necessarily entail a larger screen or

- A smaller laptop computer with an external keyboard, mouse and maybe even external screen. We don't recommend wireless external keyboard or mouse. Battery replacement is expensive and environmentally irresponsible.

Backup system

Once you start using mSupply, it is of crucial importance that you have a method of backing up your data. mSupply stores all its data in a file that rapidly becomes large. You need, therefore, to have a high capacity removable storage device. We strongly recommend the use of an external hard disk using either firewire (IEEE 1394) or USB2 to facilitate off-site storage of backups.

- See the section in Preferences that covers mSupply's built-in backup features that allow backup to another disk, and to an internet backup site… you'll find it here: Backup

- If not using our internet backup service, you need to be able to store backed up data off-site to prevent the risk of loss by fire, theft, etc.

Sustainable Solutions will not be able to help you recover lost data in the event of hardware failure if no backup is available.

Antivirus

Windows based operating systems are particularly prone to malware if precautions are not taken. We recommend the following precautions:

- Install a reputable anti-virus program, including web protection if the computer has access to the internet.

- Disable USB ports - refer to this site for suggested methods.

Ensure that access to passwords to allow exceptions to the above two measures are kept secure.

Upgrading mSupply from previous versions

If you open a data file that was created with a previous version, it will automatically be updated to the new format. Please note that this process may take some time.

Note that if you are using a version earlier than v1.96 you must first upgrade to v1.96 and then to version 2 or 3.

IMPORTANT! Always make a backup of your data file before upgrading, and preferably keep a copy off-site. We will not be able to help you in the event of some unexpected disaster if you haven't followed this advice!

| Previous: 2. Setting Up mSupply: Technical Guide | | Next: 2.02. Installation |

2.03. Starting mSupply for the first time

To start mSupply, either

- double-click the start mSupply icon on your desktop, or

- choose the start mSupply item from the mSupply menu in the programs section of the Start menu (on Windows). If this is the first time mSupply has been started after installation, then an example data file will be opened allowing you to follow the mSupply tutorial. mSupply will present you with a log in window.

Note that mSupply will “remember” the last data file used, and automatically present the log-in window for that file unless you move or rename your data file. If you do this, mSupply will show you a standard open/save window for you to choose the new name/location of your data.

Creating a new data file

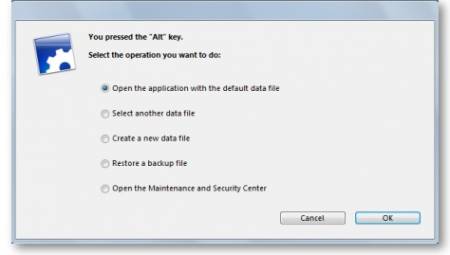

Create a new data file while opening mSupply:

- Quit mSupply if it is running.

- Choose the 3rd radio button Create a new data file.

- Another window will open where you can choose the location and name of your new data.

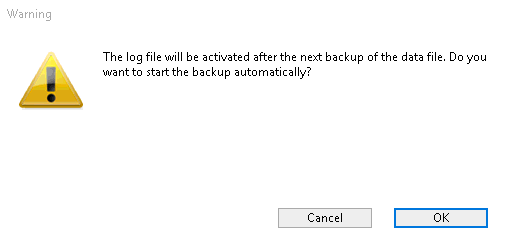

- You will be prompted for where to create the log file. Generally, it is OK to put the log file in the same location as the data file.

Default file location

- Once mSupply has opened a particular data file, that data file becomes the default data file, and will be opened on restarting mSupply.

- To open a different file, it must be chosen as described later.

- If the default data file is renamed or moved to a different location, it must be opened using its new name or location.

Log-in to mSupply

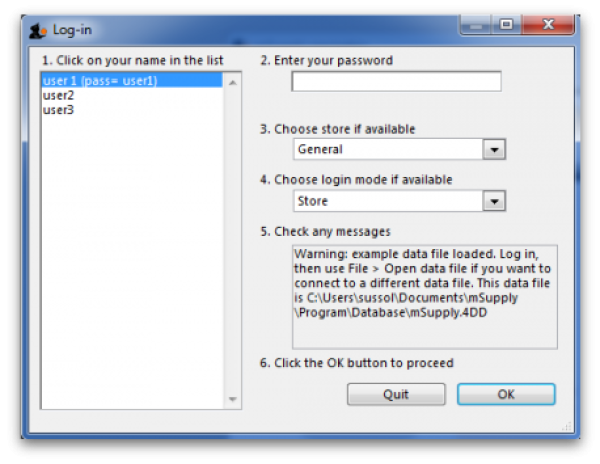

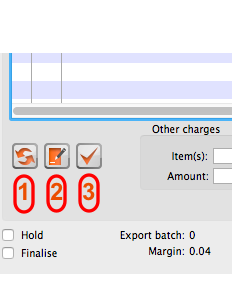

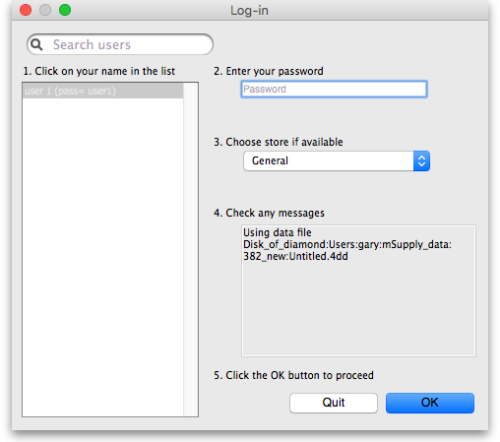

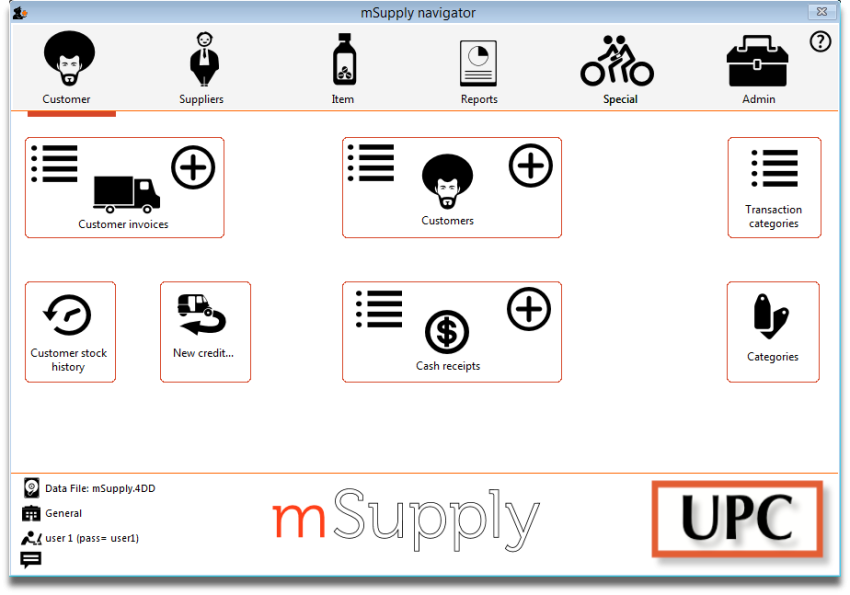

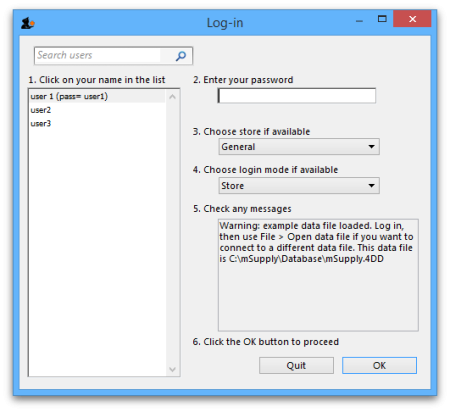

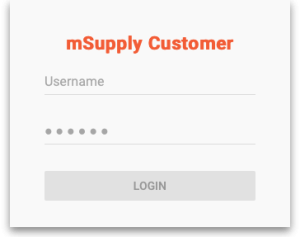

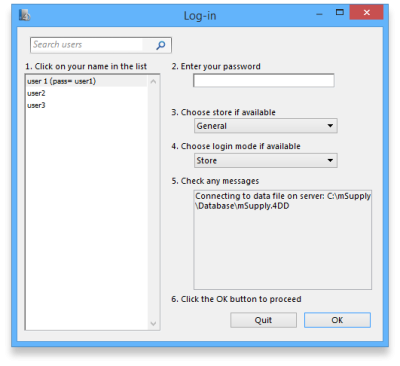

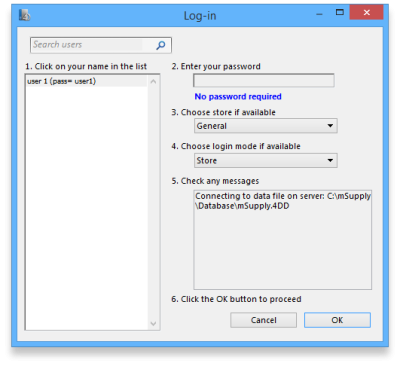

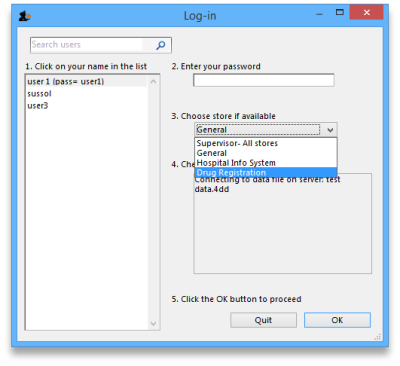

The first time you use mSupply, you will be presented with the log-in window like this:

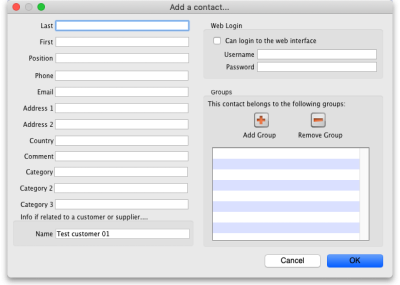

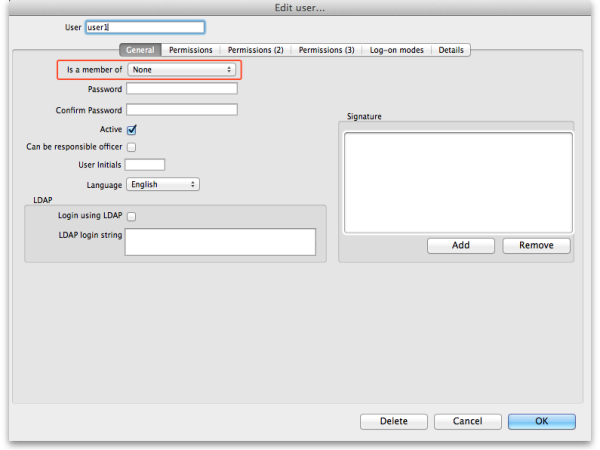

mSupply® ships with three users. “user 1” and “user 2” are the designer and administrator - these two users cannot be deleted, but they can be edited, allowing the use of appropriate names and making changes to their passwords and permissions.

- You should select user 1(pass=user1) from the list

- Enter the password “user1” (without the quotes). When different users with their own level of access have been set up, you will then log-in by selecting your user name and typing your own password.

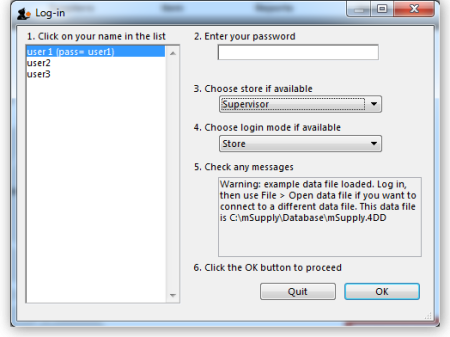

- From the drop down list, select the store with which you are working. Most mSupply users will be operating with a single store, but for users operating with more than one store, the login screen allows you to select any of the stores to which you have access. After selecting the desired store, all transactions will relate to that store until you return to the login screen and select a different store from the drop down menu.

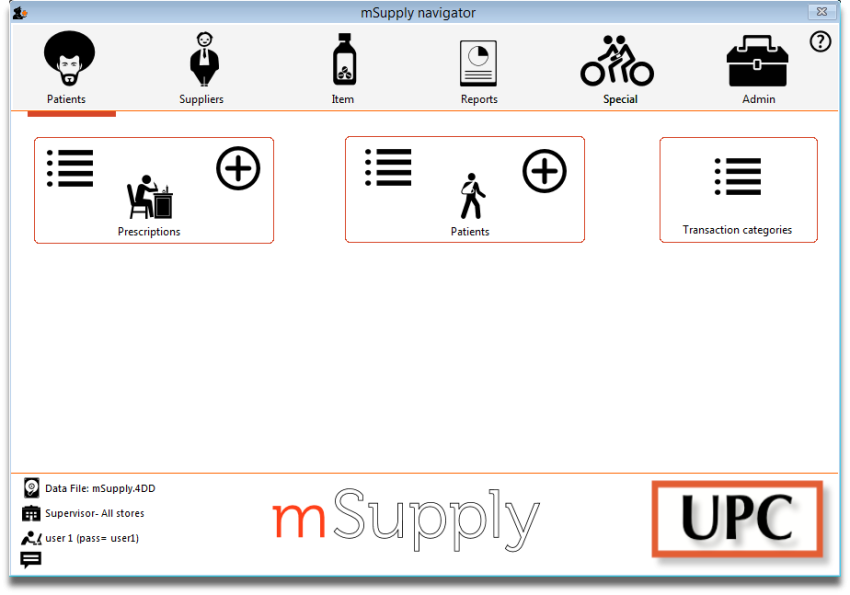

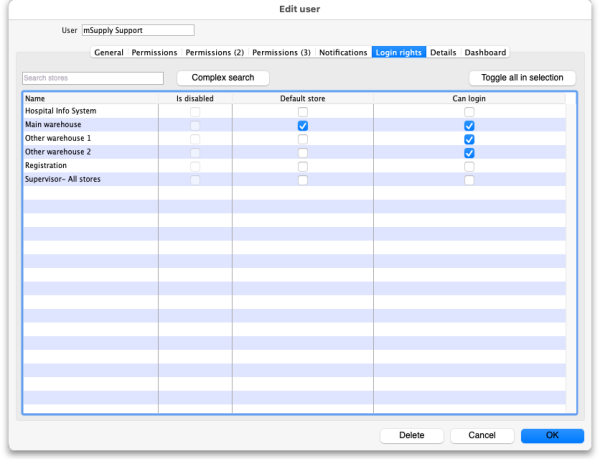

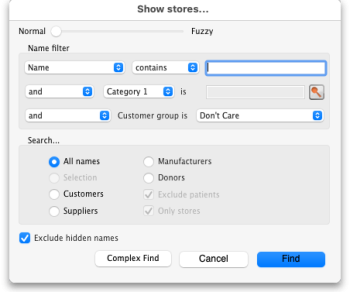

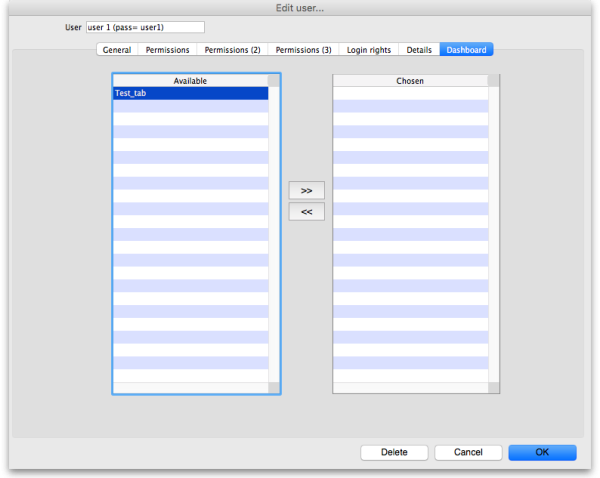

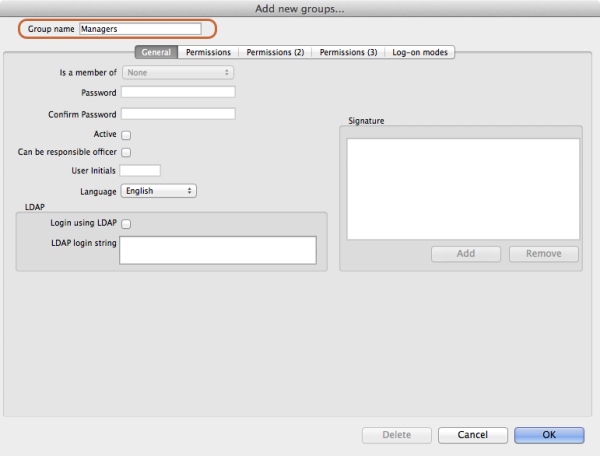

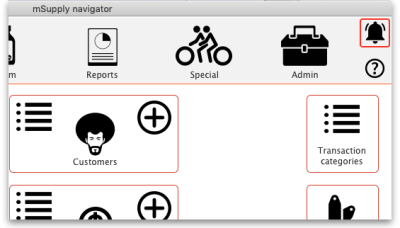

- Supervisors and other Level 1 users will have an additional menu item, Supervisor - All stores . In this mode, all stores are accessible, and you would use this mode, for instance, when placing an order for supplies which will be distributed to a number of stores. Further information is available here: Show stores

Finally, click OK to login

Preparing mSupply for actual use

The following 2 steps are necessary to start mSupply for the first time.

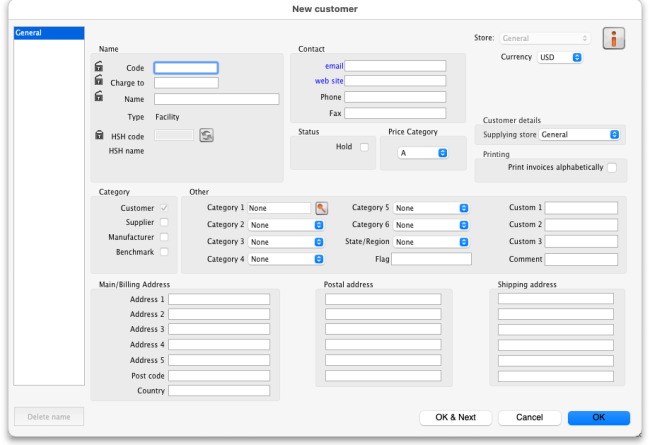

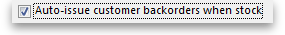

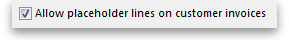

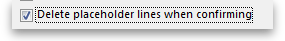

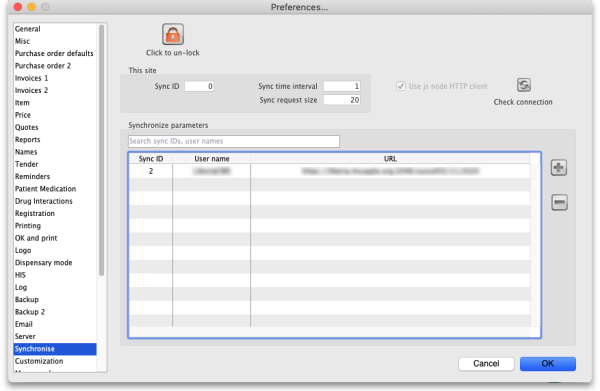

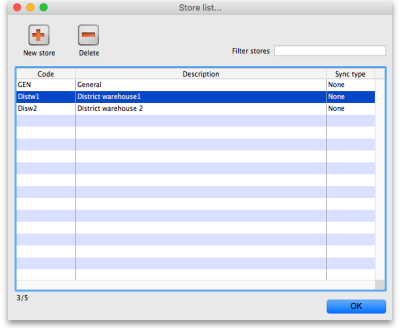

- Create a new data file

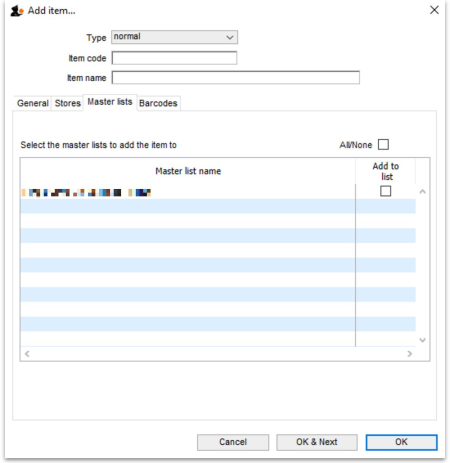

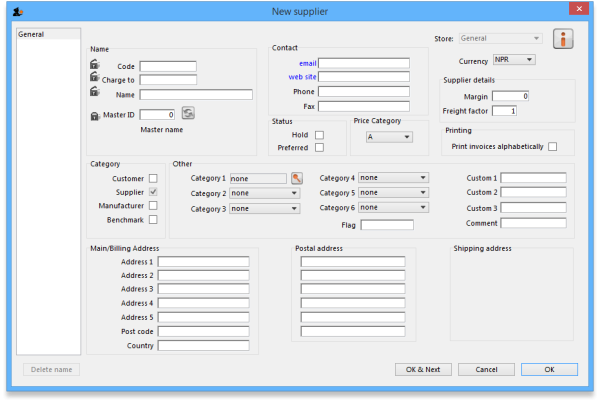

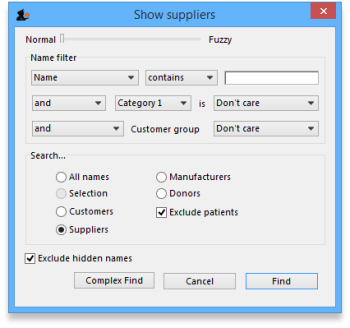

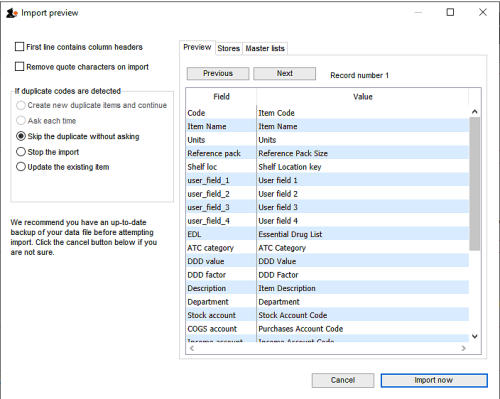

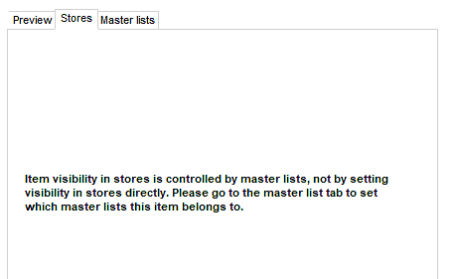

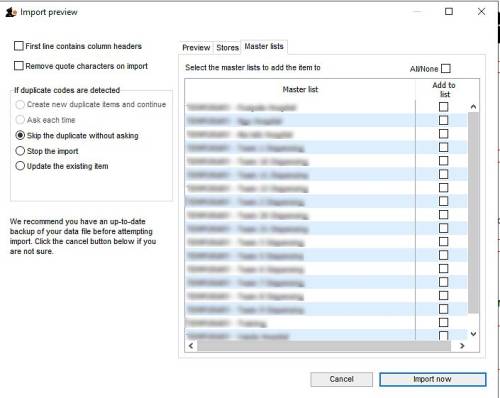

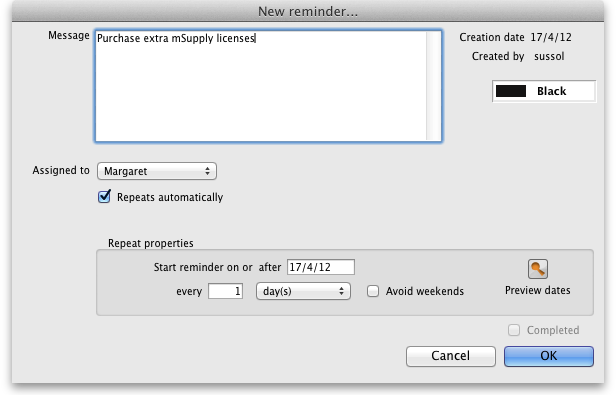

- Prepare the new data file for use